Method and device for co-production of coal gas and semi-coke by atmospheric-pressure high-temperature pyrolysis of pulverized coal with oxygen-enriched oxidation

A high-temperature pyrolysis and high-temperature gas technology, which is applied in the details of gasification units, granular/powder fuel gasification, and gasification processes, etc., can solve the problems of complex equipment system, high cost, and wide application of disadvantageous technologies, and achieve simple maintenance. , the effect of high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

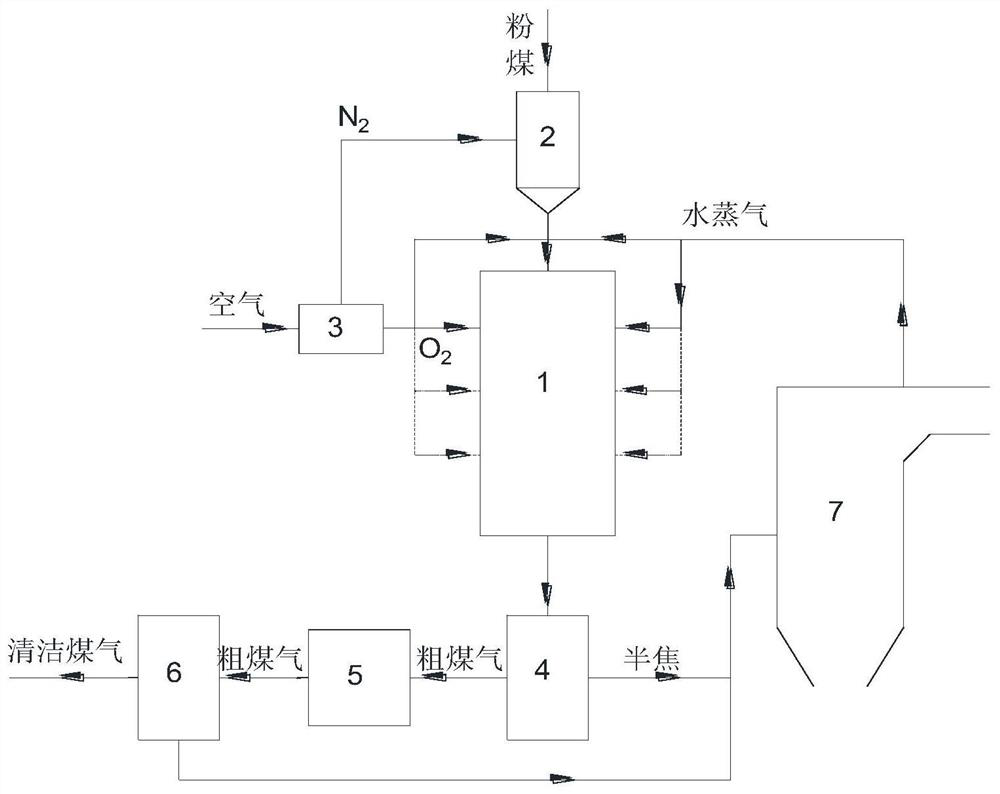

[0045] Specific implementation mode 1 ( figure 1 )

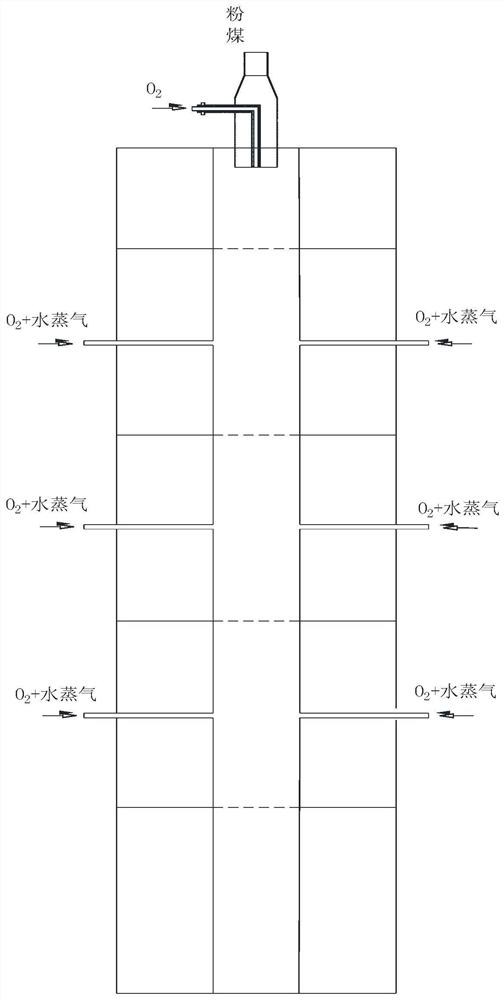

[0046] The dry pulverized coal is transported into the high-temperature cracking gasifier 1 through the nitrogen generated by the air separation device 3, and undergoes cracking and gasification reactions with the oxygen generated by the air separation device 3 in the environment of high temperature and normal pressure in the furnace to produce coal gas and semi-coke . The inlet of the gasification medium is arranged on the top of the high-temperature cracking gasification furnace 1 and along the furnace body, which can realize the centralized or segmented feeding of oxygen and water vapor. After the reaction product is separated by the high-temperature gas-solid separator 4, the gaseous crude gas enters the waste heat recovery device 5 and the gas purification device 6 to recover the sensible heat of the high-temperature gas and output clean gas; the solid semi-coke is sold as high-quality activated carbon raw material or ...

specific Embodiment approach 2

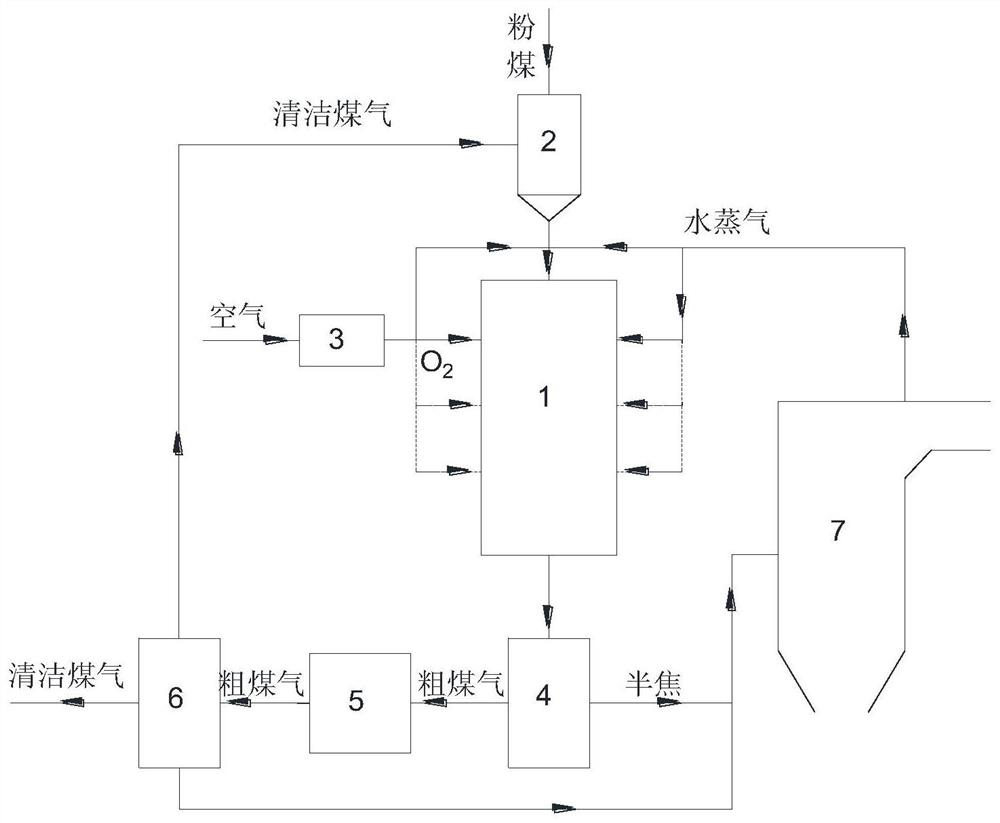

[0047] Specific implementation mode 2 ( figure 2 )

[0048] The dry pulverized coal enters the high-temperature cracking gasifier 1 through the clean gas from the gas purification device 6, and undergoes cracking and gasification reactions with the oxygen generated by the air separation device 3 in the furnace at high temperature and normal pressure to produce coal gas and semi coke. The inlet of the gasification medium is arranged on the top of the furnace and along the furnace body, which can realize the centralized or segmented feeding of oxygen and water vapor. After the reaction product is separated by the high-temperature gas-solid separator 4, the gaseous crude gas enters the waste heat recovery device 5 and the gas purification device 6 to recover the sensible heat of the high-temperature gas and output clean gas; the solid semi-coke is sold as high-quality activated carbon raw material or sent to combustion The boiler 7 is used for combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com