T-method motor speed measurement method of four-way parallel sampling

A technology of motor measurement and speed measurement, which is applied in the direction of devices using optical methods, can solve the problems of reducing the accuracy of speed measurement, and achieve the effects of high dynamic response speed, low dynamic speed measurement error, and high speed measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

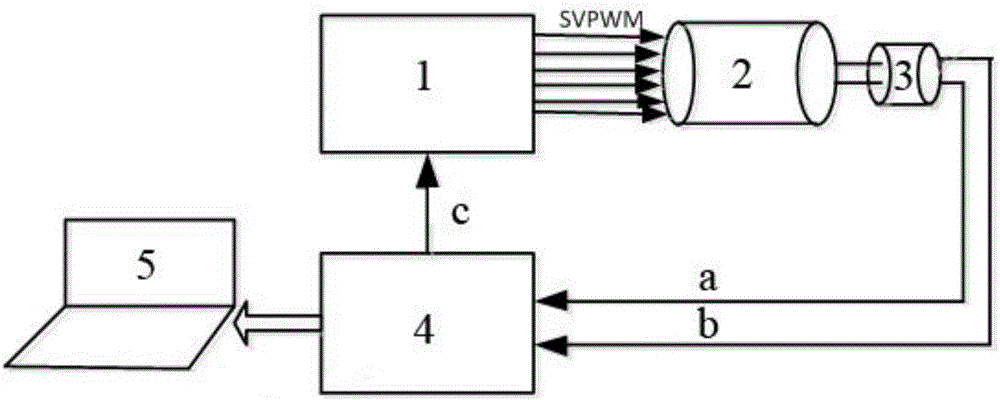

[0026] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

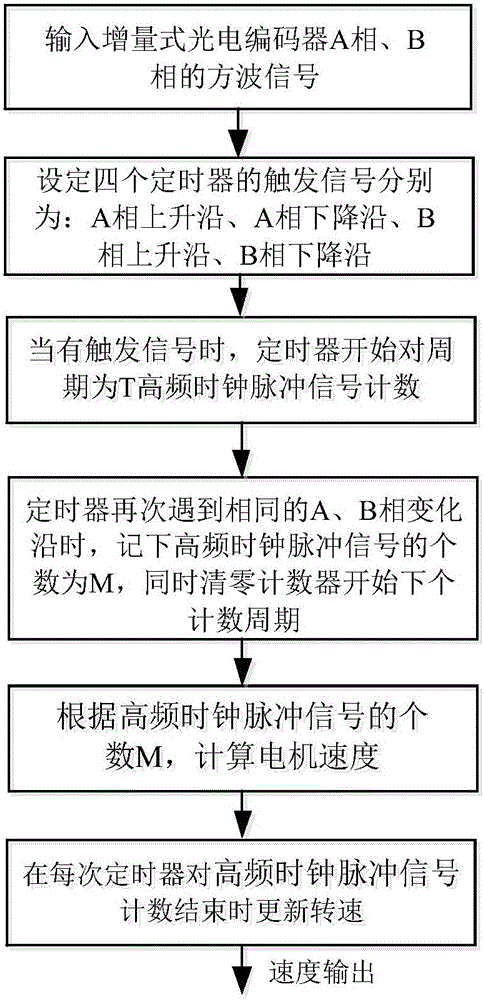

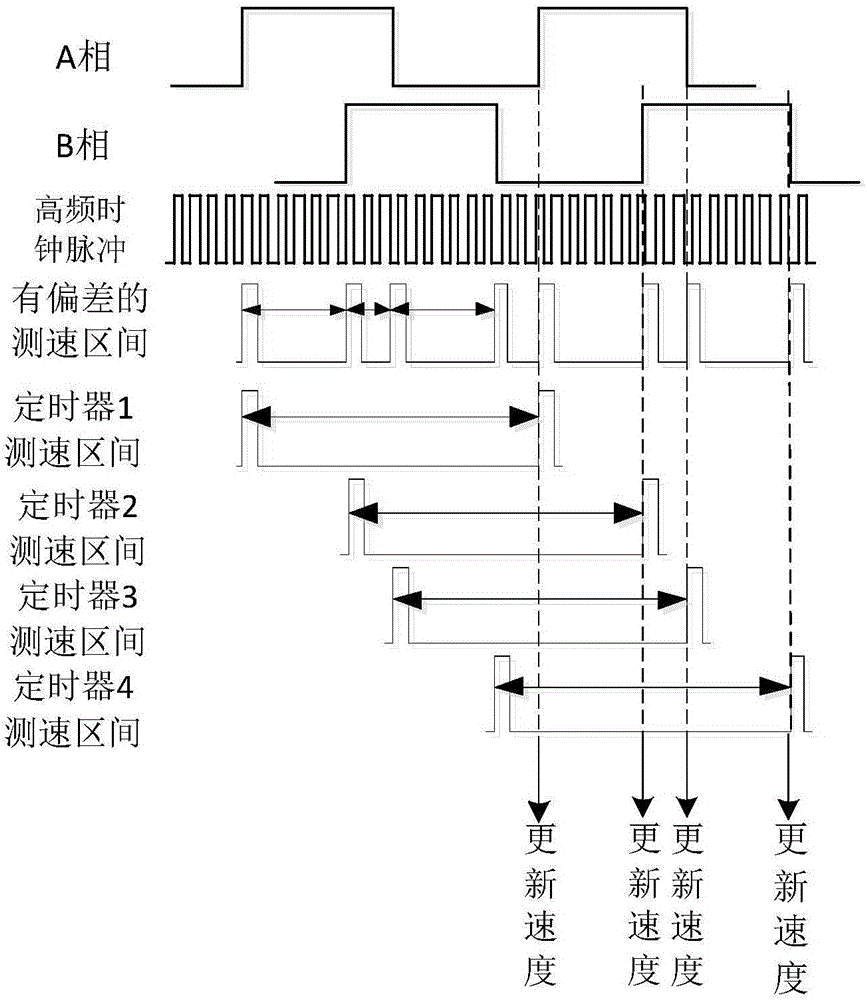

[0027] The present invention is a four-way parallel sampling T method motor speed measurement method, the speed measurement method is as follows: figure 2 shown, and the specific description is as follows:

[0028] 1) The incremental photoelectric encoder outputs square wave signals of phase A and phase B to input the signal processing controller, and the trigger signals of the four timers are set as: rising edge of phase A, falling edge of phase A, rising edge of phase B , Phase B falling edge;

[0029] 2) When step 1) ends and when there is a trigger signal, the timer begins to count the period as T high-frequency clock pulse sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com