Wheel hub electric machine

A technology of in-wheel motor and motor cover, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of synchronous detection of in-wheel motor speed without consideration, poor working stability, small transmission torque, etc. The effect of transmitting large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

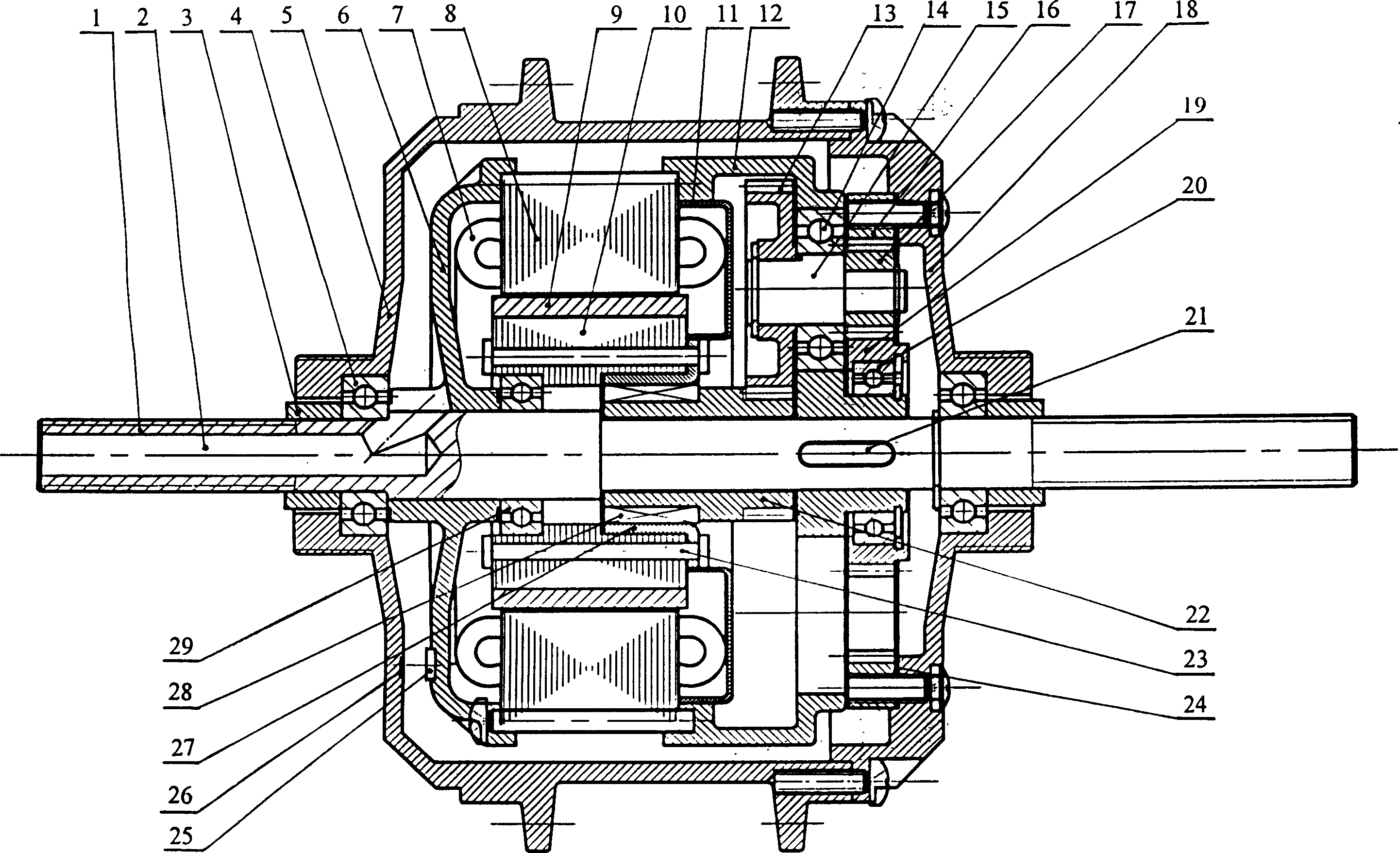

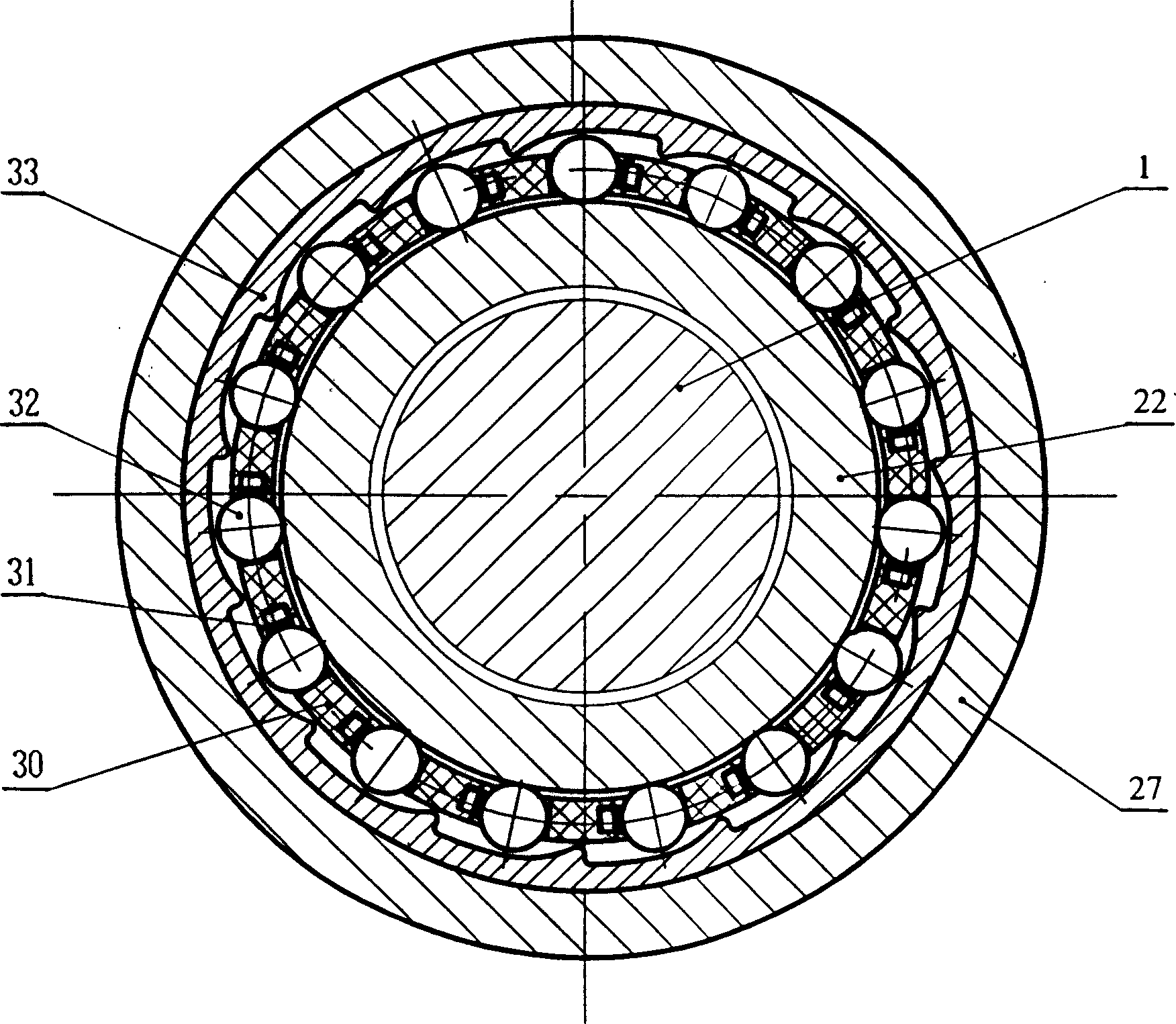

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] Such as Figure 1-Figure 2 As shown, the in-wheel motor has a shell composed of a motor main shell 5 and a motor cover 18 which are fixedly connected with each other by screws. A straight-through main shaft 1 is arranged in the symmetrical center shaft hole of the shell, and the two ends are respectively connected by bearings 4 and 1 in the shaft hole of the shell. The bushing 3 is used as a support, and the stator left end cover 6 and the stator right end cover 12 fixedly connected with it are set on the main shaft, that is, the stator right end cover is connected with the main shaft by a flat key 21, and the stator left end cover is connected with the stator right end cover through screws, so that the stator left , the right end cover and the main shaft form a static connecting body. In the left and right end covers of the stator, there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com