High-altitude operation platform based on PLC control and use method thereof

A high-altitude operation and platform technology, which is applied in the field of lifting platforms, can solve problems such as limited space for ladders, potential safety hazards, and the center of gravity of the platform deviates from the center position, so as to increase the safety of electricity consumption, reduce the loss of electricity consumption, and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

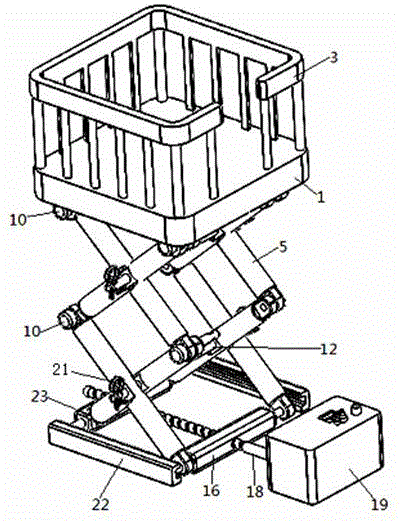

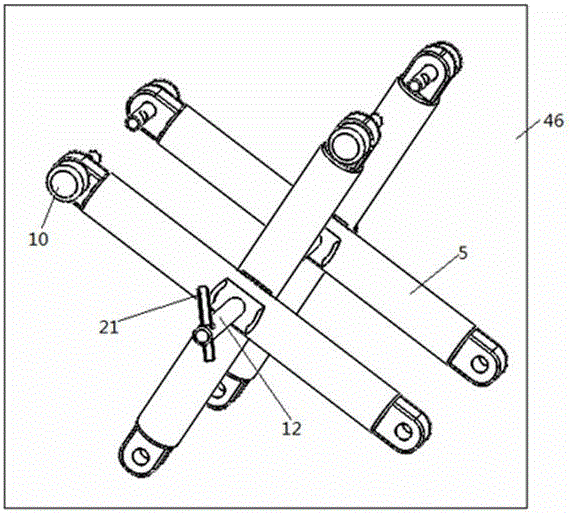

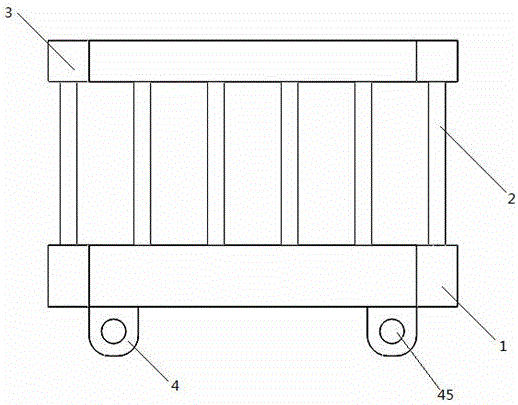

[0051] to combine Figure 1-15 As shown, a high-altitude operation platform based on PLC control includes a base plate 1, a support rod group 46, a screw 18, a power module 19, a control device 20, a front slide 16, a rear slide 23, a PLC controller 17, a slide Rail 22; railing 2 is installed around the upper side of the base plate 1; the other end of the railing 2 is connected with a guardrail 3; a pair of lug plates 4 are slidingly installed at the four corners of the bottom side of the base plate 1; lug plate holes are opened on the lug plate 4 45; each pair of ear plates 4 is connected with the ear plate joint 6; the support bar group 46 includes the support bar 5 and the synchronization bar 12; the lower side of the ear plate joint 6 is welded to one end of the support bar 5; the other end of the support bar 5 is connected to the other end A lug plate joint 6 is welded; a connecting hole 9 is opened at the center of the front of the lug plate joint 6; the connecting hole ...

Embodiment 2

[0054] A method for using a high-altitude operation platform based on PLC control, comprising the following steps:

[0055] a. Move the high-altitude operation platform based on PLC control to the accident / maintenance location;

[0056] b. Turn on the power supply; turn on the power button 29, and the circuit is powered on;

[0057] c. Select different gear buttons 30 to adjust the raising speed;

[0058] d. The control device 20 controls the action of the deceleration motor 35, and the screw 18 drives the front slide 16 and the rear slide 23 to move in opposite directions. According to the height of the point to be repaired / equipment to be repaired, the support rod group 46 raises the operating platform to the required height ;

[0059] e. The maintenance personnel maintain the equipment, and the maintenance personnel can move and change positions on the operation platform;

[0060] f. After the repair and maintenance is completed by the maintenance personnel, the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com