Automatic management system of intelligent instant dynamic factory

A technology of factory automation and management system, applied in the field of real-time dynamic factory management system, which can solve the problems of failed security inspection, affecting production efficiency, and loose monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

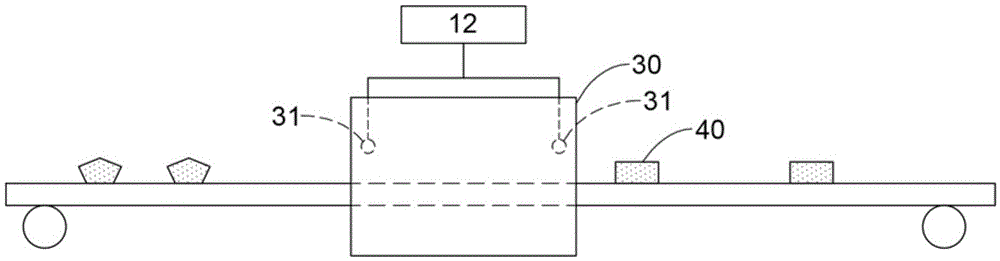

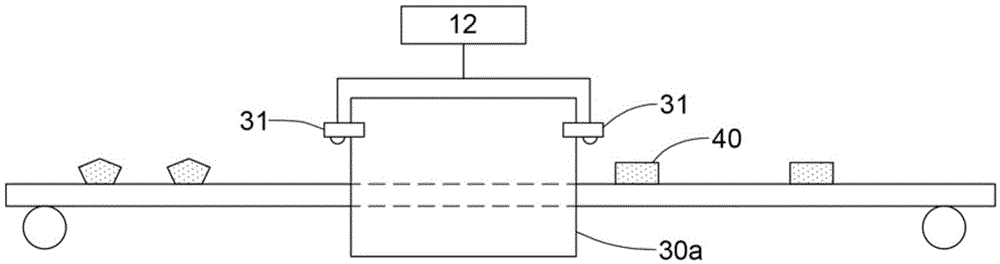

[0049] The present invention proposes an intelligent real-time dynamic factory automation management system, which can be applied to stand-alone production (such as injection molding equipment) or manual production of discontinuous production lines in factories, and can also be applied to continuous production lines (such as printing of printed circuit boards). , baking, etching and other continuous processes).

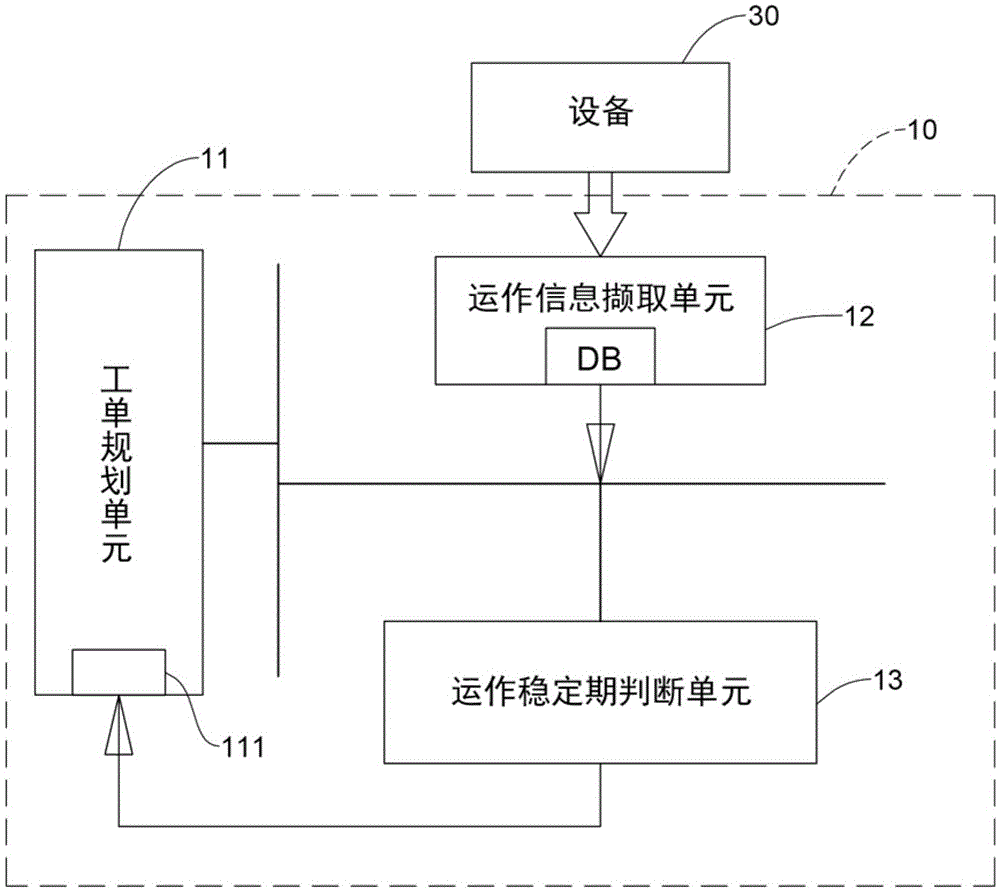

[0050] See first figure 1 As shown, it is an embodiment in which the intelligent real-time dynamic factory automation management system 10 of the present invention is applied to a single device 30 in a factory. The intelligent real-time dynamic factory automation management system 10 includes a work order planning unit 11 and an operation information acquisition unit 12 and an operation stable period judging unit 13 . After the management personnel of the factory set up the relevant production information according to the current products to be produced, the work or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com