Method for panoramic inspection on substation

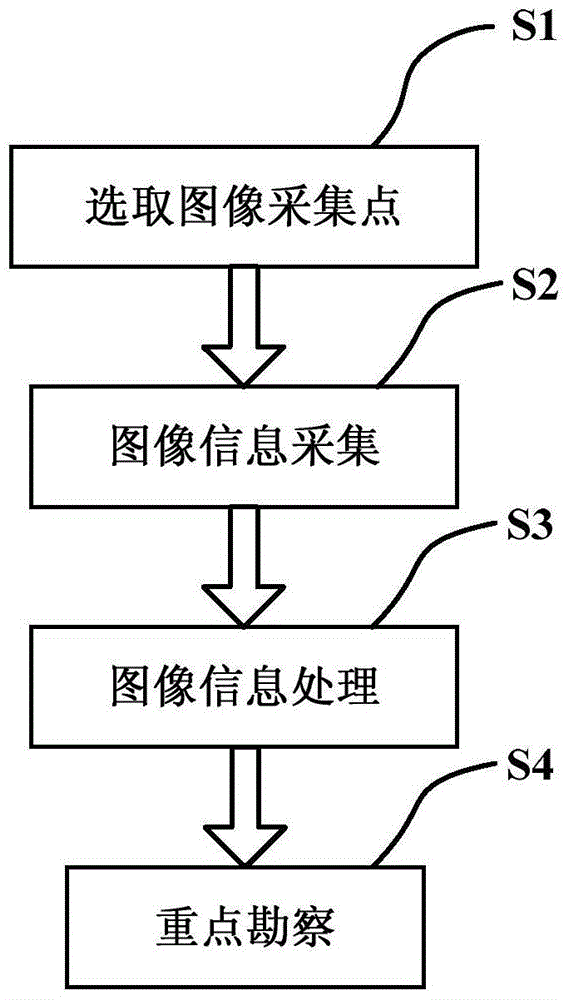

A substation and panoramic technology, applied in the field of electric power system, can solve the problems of inconvenient control of motion range, low efficiency, complex environment, etc., and achieve the effect of reducing inspection omissions and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

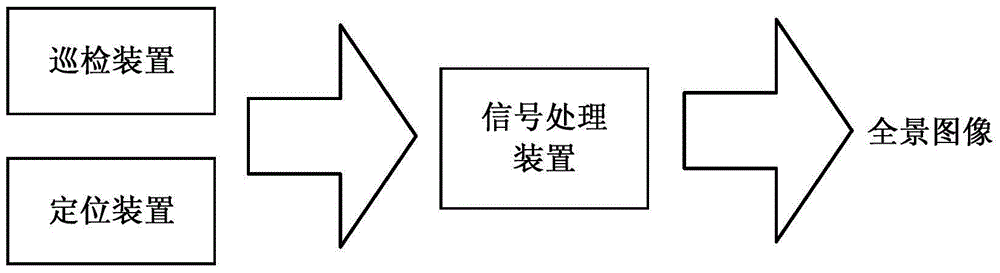

[0079] The inspection equipment uses a thermal infrared imager as the inspection device, GPS and gyroscope as the positioning device, and the positioning device and the lens of the thermal infrared imager are located on the same optical axis, so that the moving direction of the lens is consistent with the direction of the detected azimuth change. GPS and gyroscope are used to measure the coordinates of the shooting location and the orientation of the optical axis of the thermal infrared imager. When the inspector first takes a view at the center of the substation, the GPS records the geographical information at this time, and the gyroscope records the angle information.

[0080] The thermal infrared imager adopts panoramic image shooting algorithm, signal processing algorithm and positioning algorithm, among which:

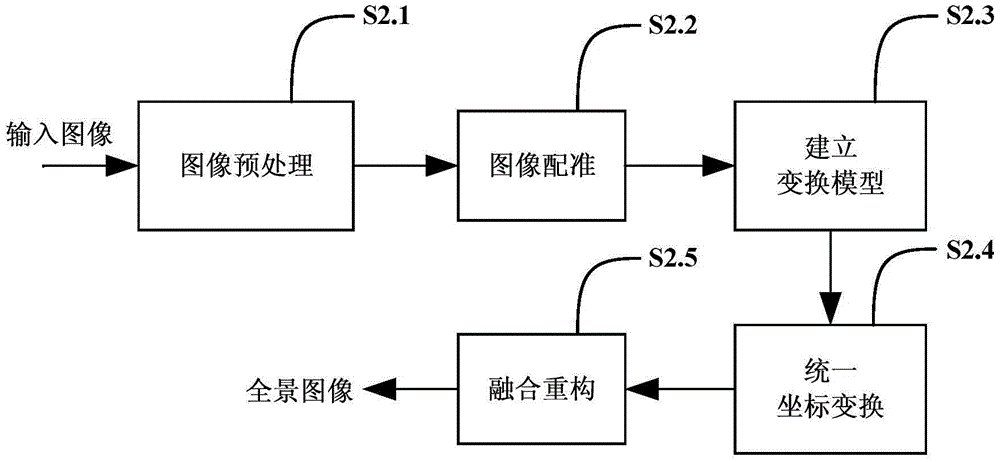

[0081] The panoramic image shooting algorithm can be implemented by extracting image edge features, first find out the overlapping parts of two adjacent images, an...

Embodiment 2

[0090] This solution can be applied to ultraviolet / infrared / visible three-channel portable inspection equipment. The inspection personnel carry out inspections in the substation with this system, which can detect the situation of the substation in all directions and all-weather, and match the fault points to the substation according to the image feature matching method. In the 3D model of the substation, guide the inspection personnel to go to the survey.

[0091] Ultraviolet detection technology is used for early fault detection of substation electrical equipment. Ultraviolet detection technology has the characteristics of no background and strong anti-interference ability, and has been widely used in substation inspection work; infrared detection technology is used for middle and late fault detection of substation electrical equipment ; Visible light equipment can directly observe the pollution of electrical equipment; combining the three, adding panoramic shooting algorithms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com