High-efficiency rotating injection mechanism for electrolyte

An electrolyte and high-efficiency technology, applied in circuits, electrical components, structural parts, etc., can solve the problem of insufficient electrolyte absorption, and achieve the effects of not easy to deteriorate, absorption, and contact probability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

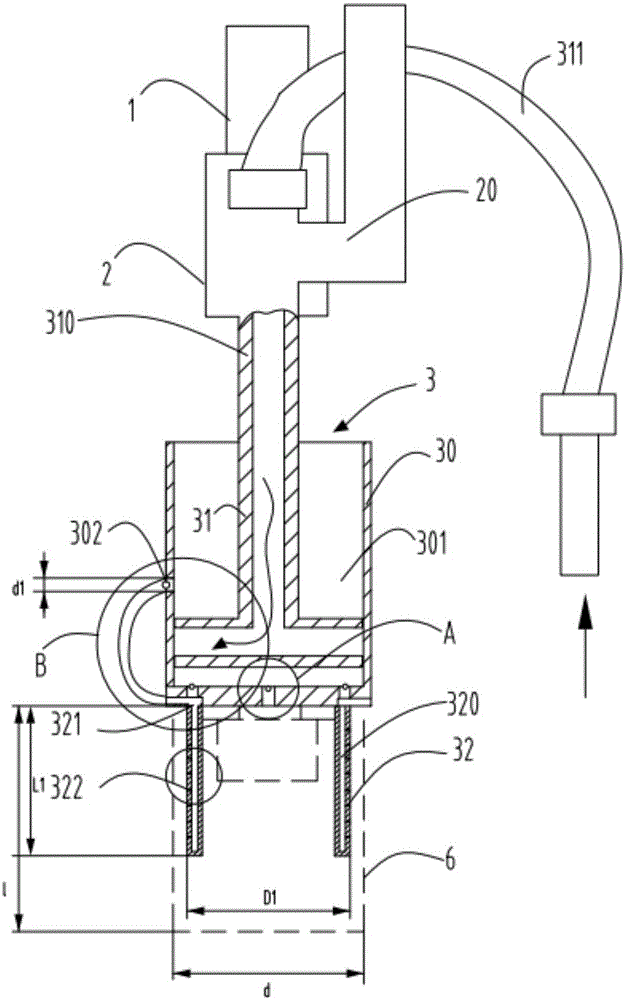

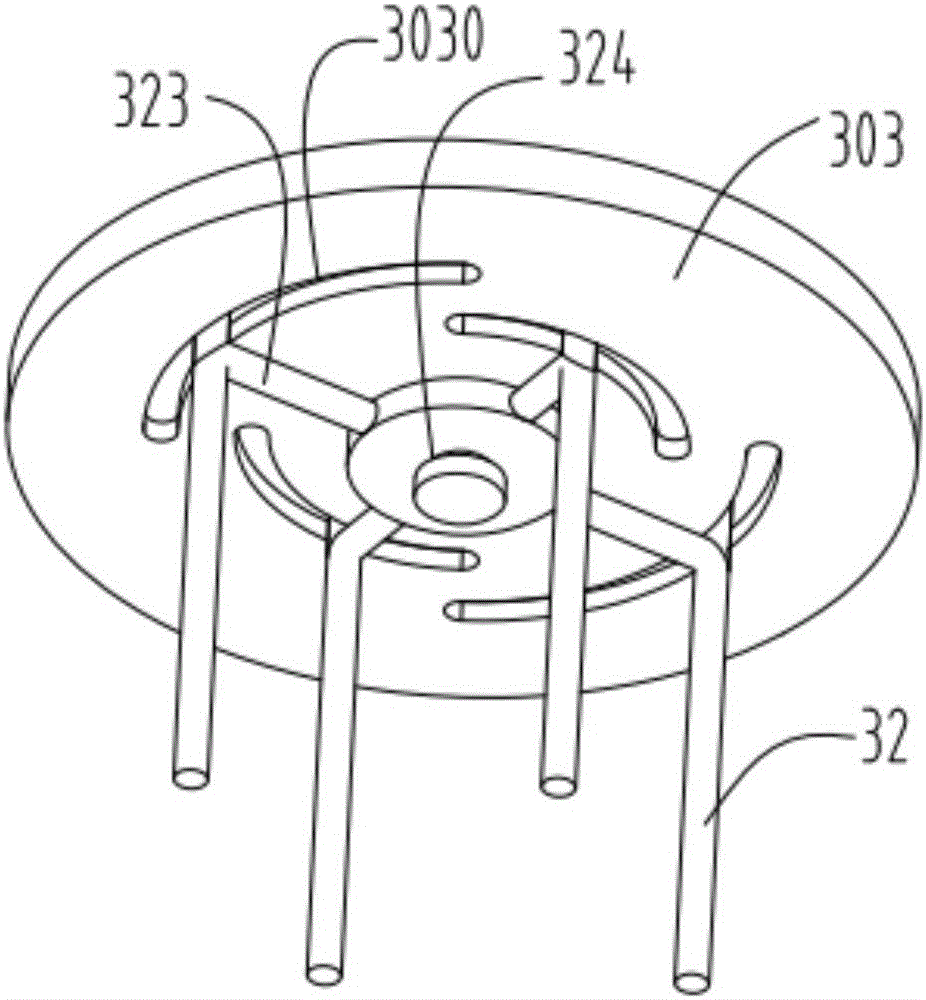

[0033] An electrolyte high-efficiency rotary injection mechanism, including a workbench 1, a slider 2 and a syringe 3, the slider 2 is movably arranged on the workbench 1, and the syringe 3 includes a first cylinder 30, An injection rod 31 and a spray gun 32 , the injection rod 31 includes a first rod body 310 and a second rod body 311 .

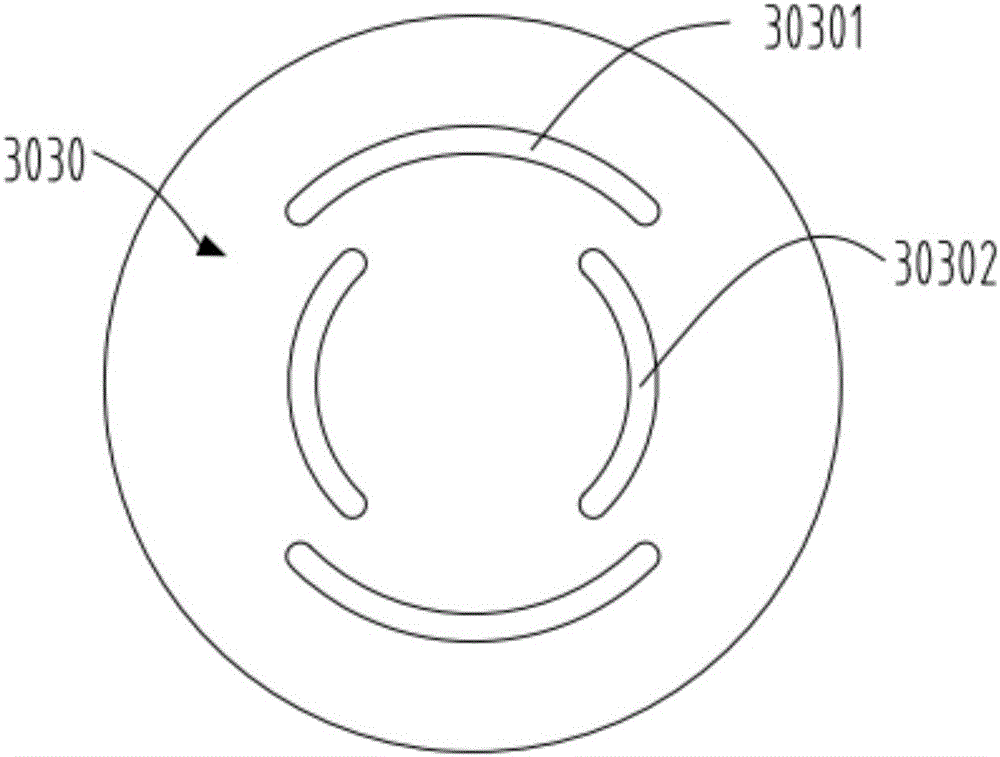

[0034] Such as figure 1 and Image 6 As shown, the first rod body 310 includes a piston part 3100, a vertical part 3101 and an electrolyte channel 3102, and the second rod body 311 is a flexible tube; the first cylinder body 30 includes a cavity 301 and a liquid outlet 302 , the piston part 3100 is movable and sealed with the cavity 301; the spray gun 32 is arranged below the first barrel 30, and the spray gun 32 is provided with a liquid channel 320 for the flow of the electrolyte, a liquid inlet A port 321 and a capillary hole 322 arranged on its outer wall; the liquid outlet 302 of the first cylinder communicates with the liquid inlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com