Cooling air guide for a friction lining brake of a motor vehicle

A technology of cooling air and guiding system, applied in the direction of brake components, brakes, brake types, etc., can solve the problems of expensive design, excessive structural space requirements, affecting the vibration characteristics of the brake cover, fatigue strength, etc., to achieve stable conveying, Improved effect of convection cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

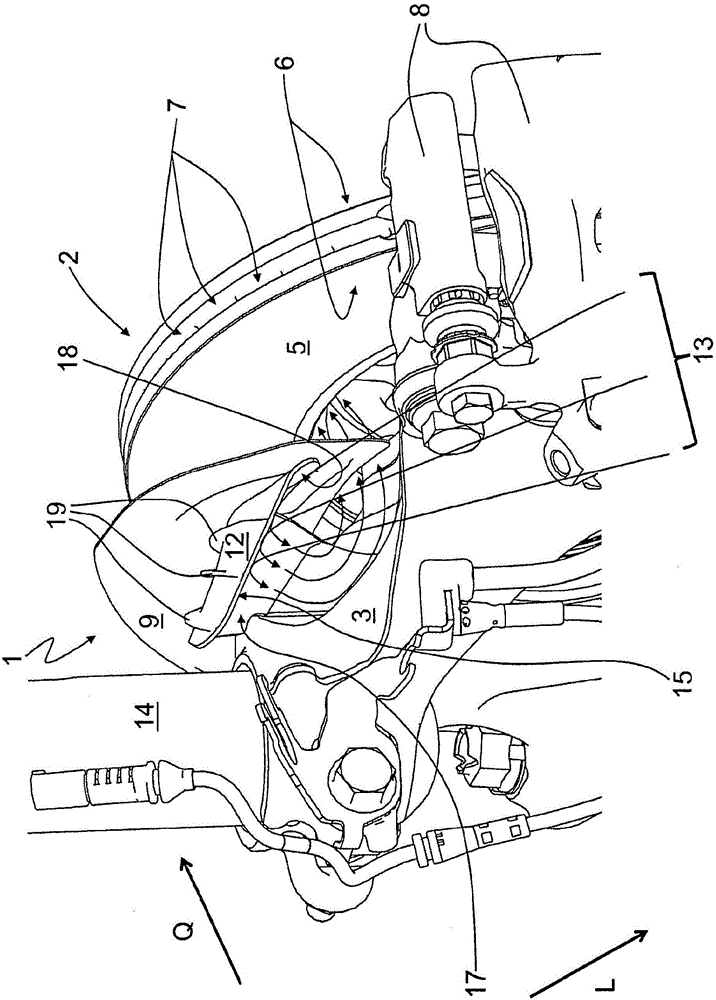

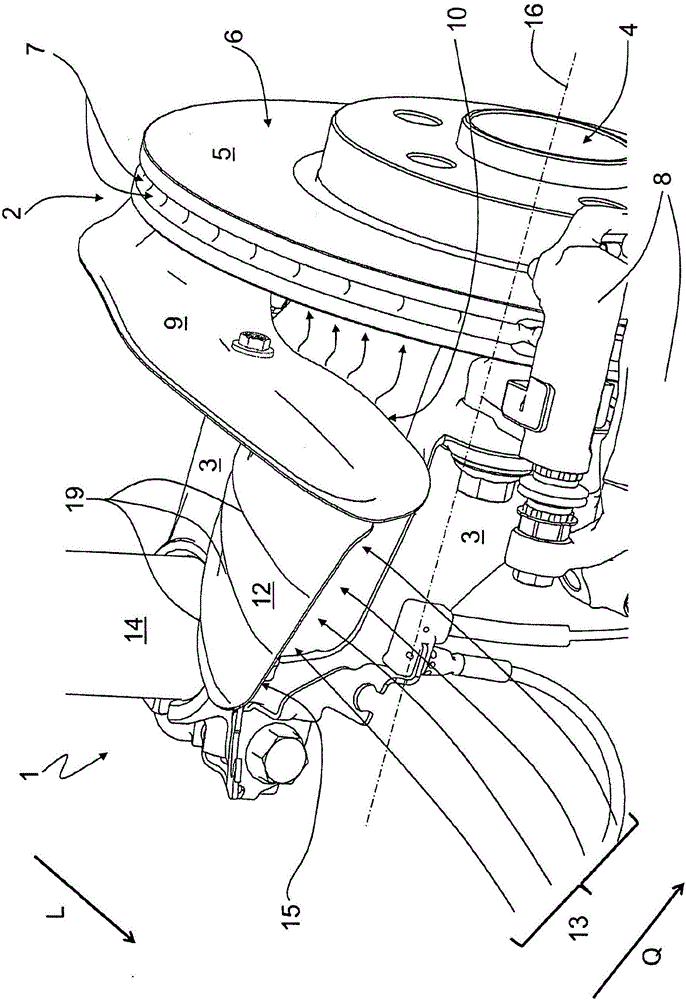

[0039] here figure 1 and 2 An exemplary embodiment of a cooling air guidance system 1 according to the invention is shown for a friction lining in the form of a disc brake 2 in a functionally installed state on the left side of the front axle of a passenger vehicle, which is formed as a strut axle. brake 2. The front axle has a damper strut 14 , which is supported with its lower end on the wheel carrier 3 or on the wheel carrier 3 , wherein, in the functionally installed state, the wheel carrier 3 passes through the damper strut 14 and a plurality of link rods (not shown here) are connected to the vehicle structure or body. Via hub 4 (reference figure 2 ), the wheel can be fastened on the wheel frame 3. exist figure 1 and 2 The damper strut shaft shown partially in the center is designed as a steerable shaft, that is, the wheel carrier 3 , which can also be referred to as pivot carrier 3 in this case, can pivot about a so-called support axis in order to be able to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com