A system and method for recovering sensible heat from molten solid matter

A sensible heat recovery and solid matter technology, applied in the field of waste heat recovery, can solve the problems of high-grade heat energy loss of high-temperature slag, small equipment investment, fresh water consumption, etc., achieve significant economic and social benefits, ensure continuity, and wide application market effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

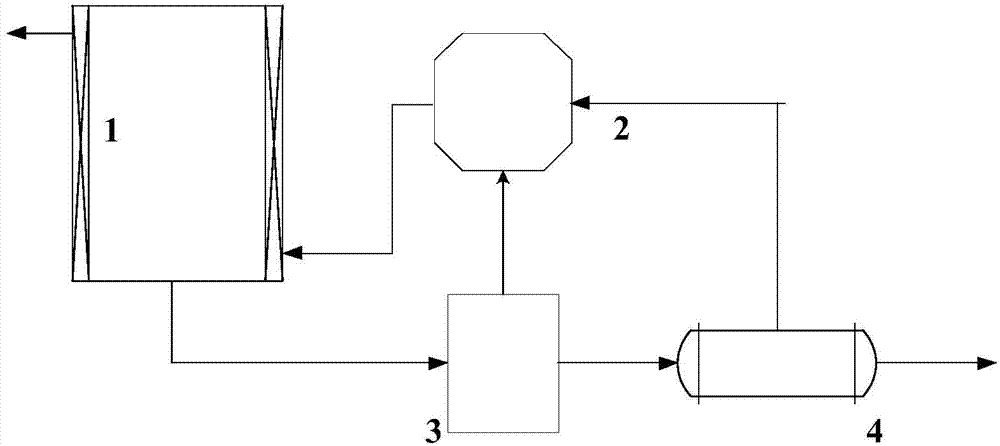

[0034] see figure 1 , a sensible heat recovery system for molten solids, comprising a pre-storage tank 1, a waste heat boiler 2, an air-cooled granulator 3 and a solid cooling device 4;

[0035] The inner wall of the pre-storage tank 1 is provided with a superheated surface, and a working fluid is passed into the superheated surface, and the molten solid enters from the inlet of the pre-storage tank 1, overheats the working fluid in the superheated surface, and then enters the air-cooled gas through the outlet. Granulator 3;

[0036] The air-cooled granulator 3 is provided with a cooling air inlet, and the molten solid is granulated in the air-cooled granulator 3 and exchanges heat with the cooling air. The cooling air is heated into hot air, and the hot air enters the waste heat from the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com