Automobile roof stamping die and machining apparatus

A technology for stamping die and automobile top cover, applied in the field of automobile stamping, can solve the problems of increasing the manufacturing process of automobile top cover, prolonging the manufacturing time, reducing the production efficiency, etc., and achieving the effects of high development cost, shortening the manufacturing time, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

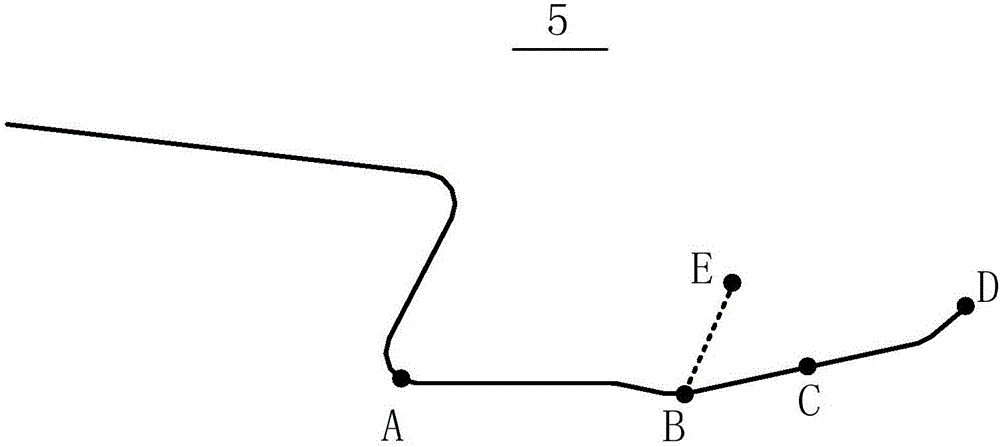

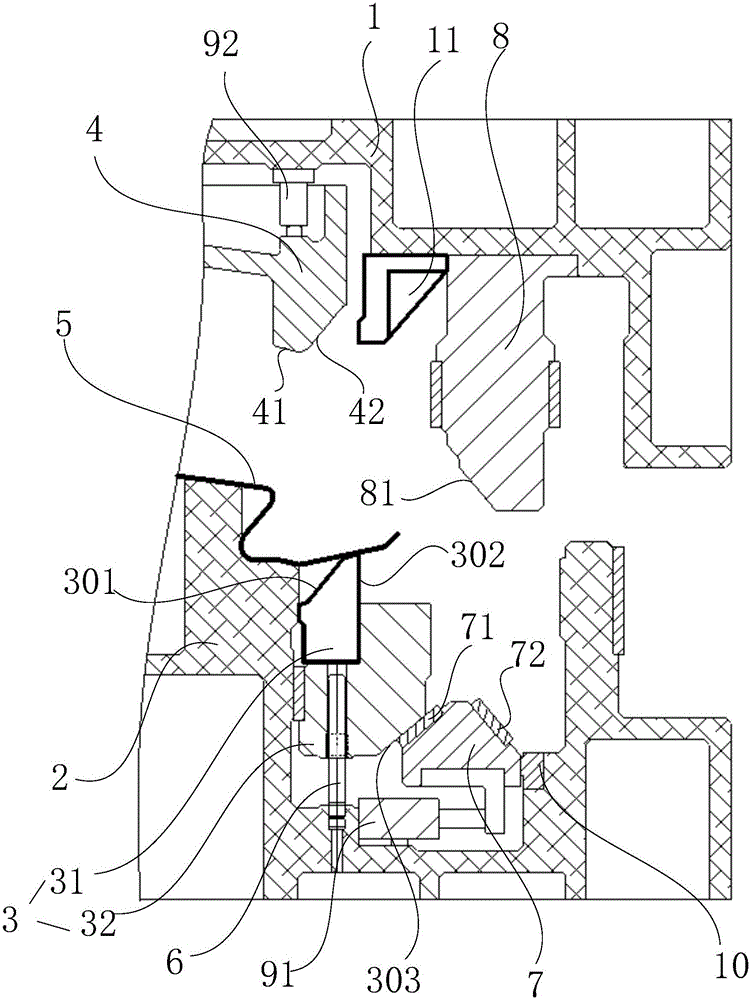

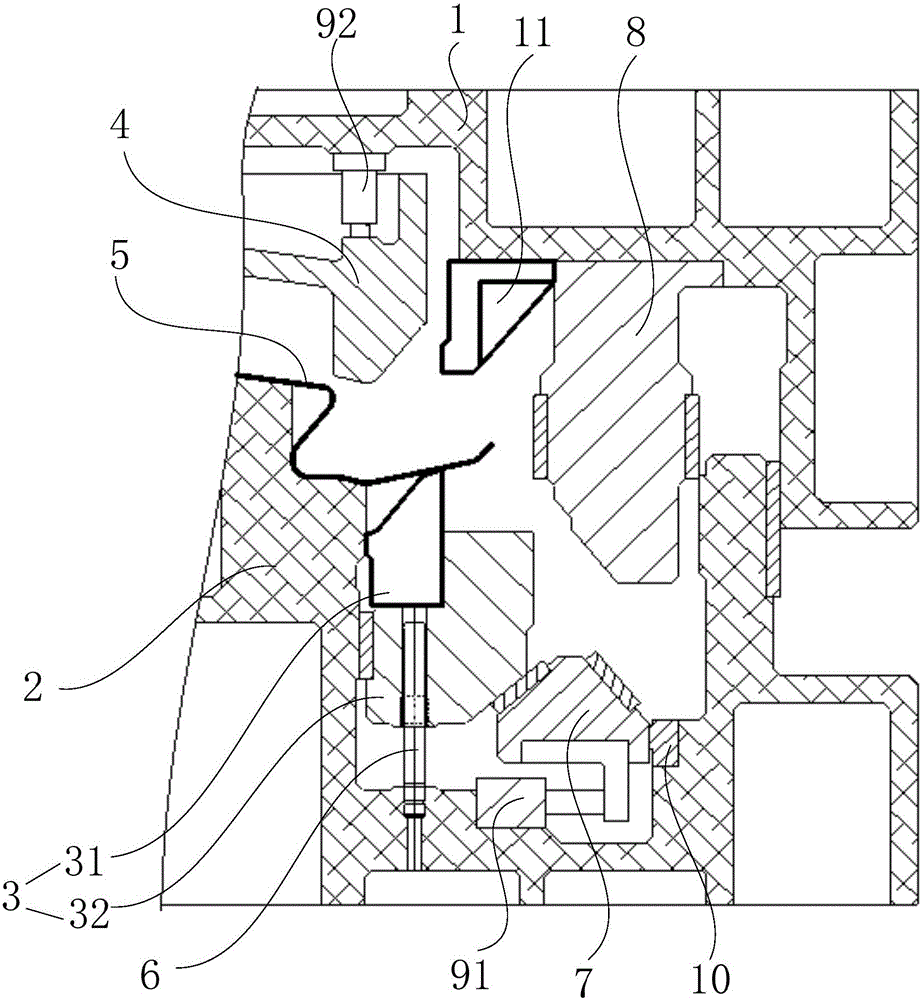

[0041] An embodiment of the present invention provides a stamping die for an automobile roof cover, see Figure 1-Figure 5 , the stamping die includes: an upper mold base 1, a lower mold base 2, a wedge 3, a pressing core 4 and a trimming tool 11;

[0042] The inclined wedge 3, the pressing core 4 and the trimming tool 11 are all located between the upper mold base 1 and the lower mold base 2, the inclined wedge 3 is arranged on the lower mold base 2, and the pressing core 4 and the trimming tool 11 are installed on the lower mold base 2 on;

[0043] The upper end of the wedge 3 is provided with an upper slope 301 and a vertical surface 302, the vertical surface 302 intersects with the top of the upper slope 301, and the vertical surface 302 is aligned with the cutting edge of the trimming tool 11;

[0044] The lower end surface of the die core 4 includes a first end surface 41 and a second end surface 42, and the second end surface 42 is aligned with the upper slope 301 of t...

Embodiment 2

[0097] The embodiment of the present invention also provides an automobile roof processing equipment, the processing equipment includes the automobile roof stamping die described in the first embodiment.

[0098] The automobile roof processing equipment provided by the embodiment of the present invention includes the automobile roof stamping die described in Embodiment 1. Through the automobile roof stamping die, the processing equipment can reduce the manufacturing process of the automobile roof and shorten the manufacturing process. time and increase production efficiency. Moreover, because the development cost of the automobile roof stamping die described in the first embodiment is relatively low, the cost of the processing equipment is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com