Axial symmetry plug type spray pipe having afterburning function

An afterburner, plug-type nozzle technology, applied in jet propulsion, machine/engine, etc., can solve problems such as weight reduction, large airflow resistance, and large thrust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

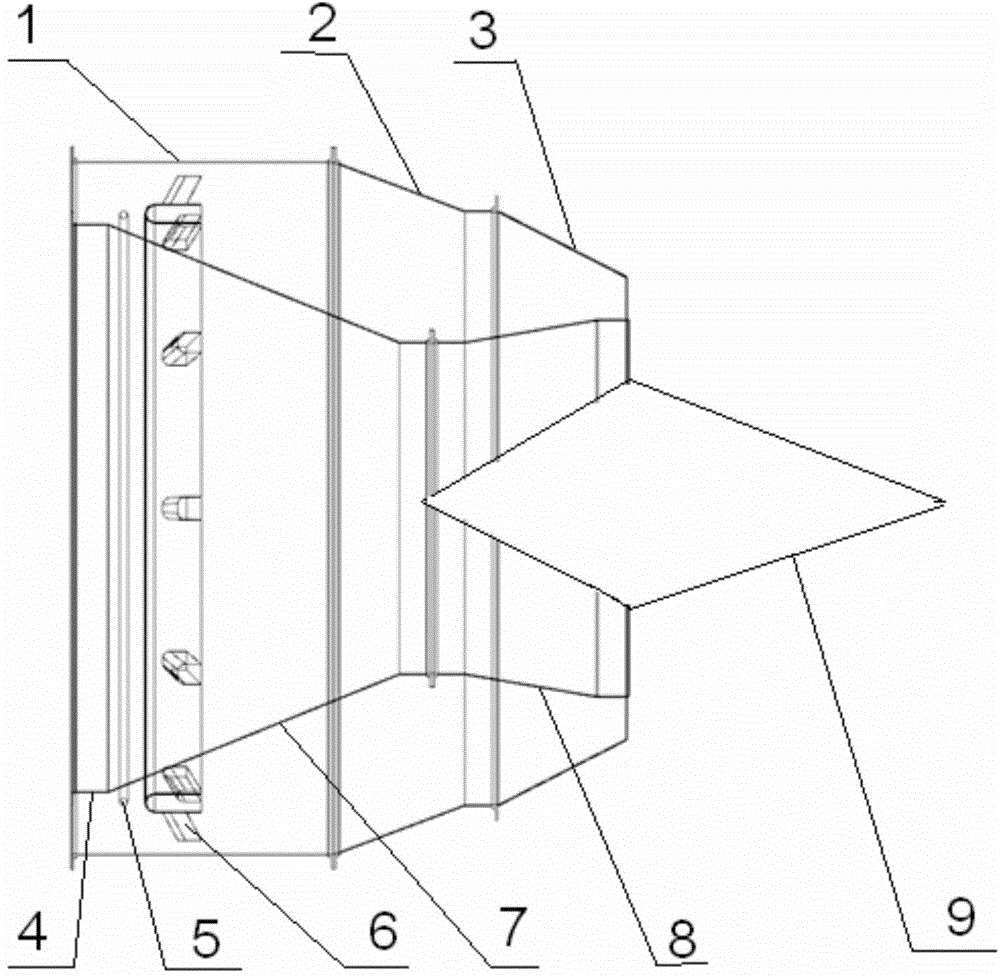

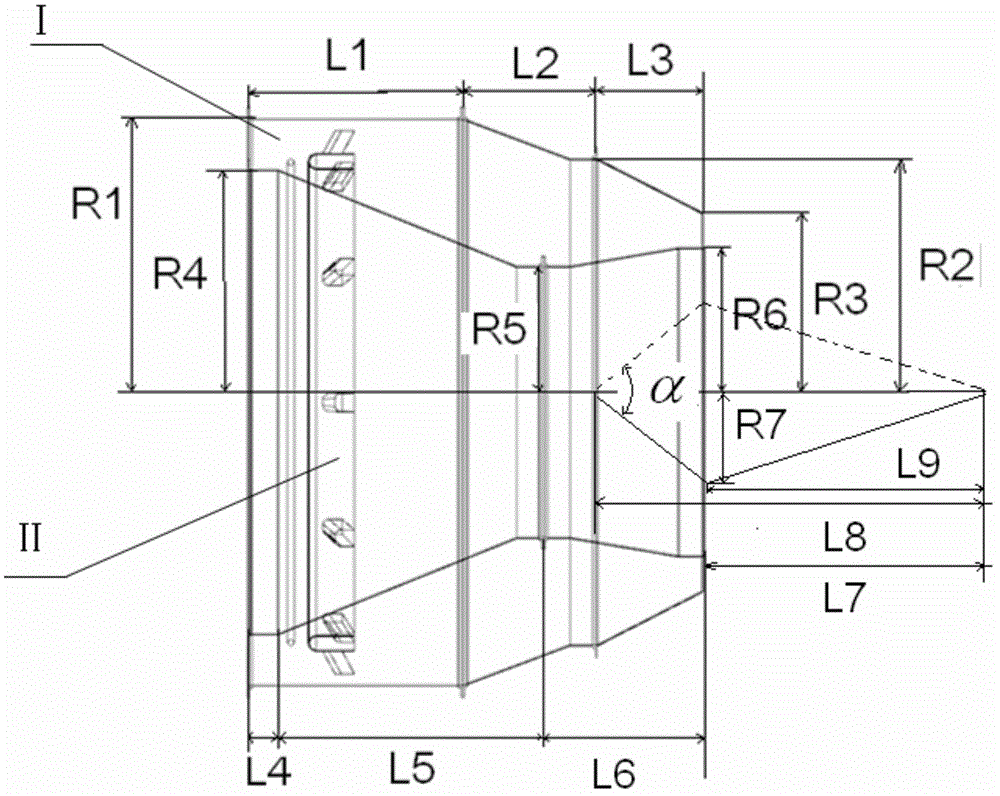

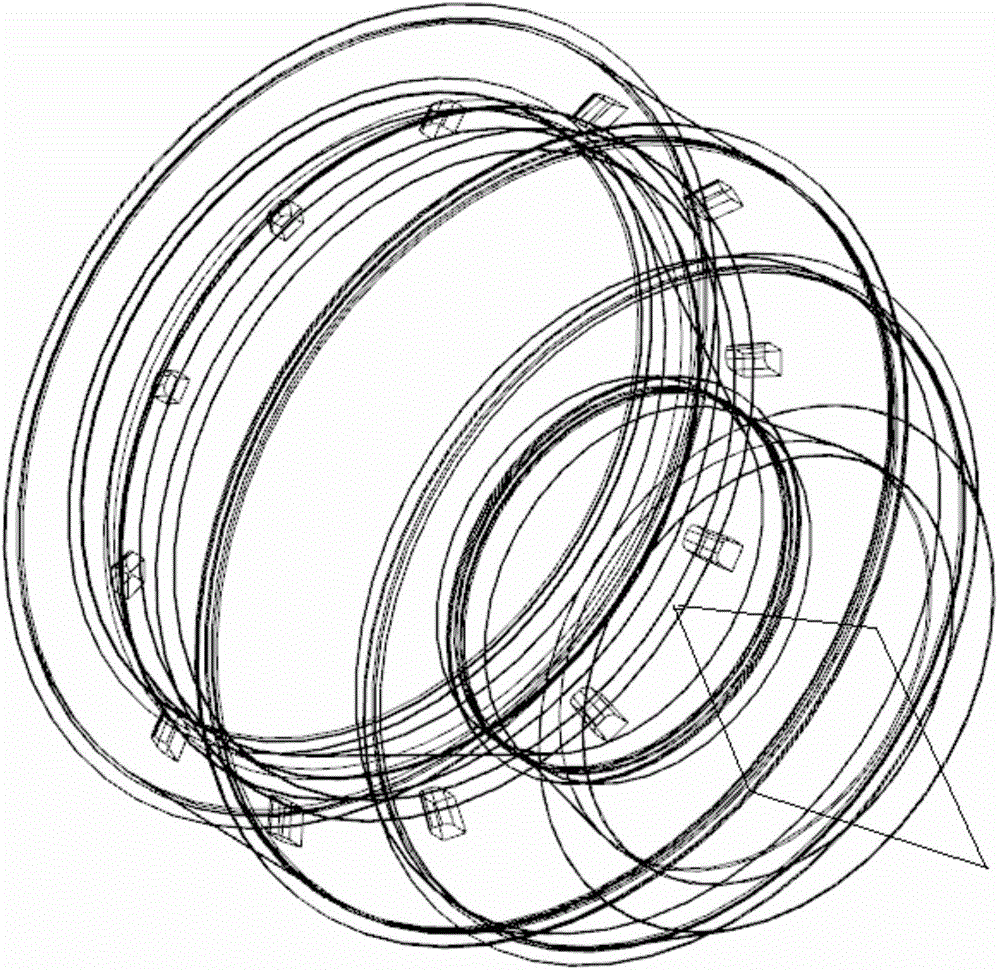

[0017] This embodiment provides an axisymmetric plug nozzle with afterburner function, which is characterized in that: nozzle outer wall barrel 1, nozzle outer wall convergent section 2, nozzle outer wall convergent section 3, nozzle inner wall barrel Body 4, fuel injection ring and ignition device 5, flame stabilizer 6, nozzle inner wall convergence section 7, nozzle inner wall expansion section 8, plug body 9, nozzle outer wall barrel 1, nozzle outer wall convergence section 2 and nozzle The converging section 3 of the outer wall of the pipe is connected with each other through the flange mounting edge to form an annular outer wall channel wall, and the inner wall cylinder 4 of the nozzle, the converging section 7 of the inner wall of the nozzle, and the expanding section 8 of the inner wall of the nozzle are connected through the mounting edge of the flange to form an annular inner wall channel Wall surface, fuel injector ring and ignition device 5, flame stabilizer 6 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com