Spherical compressor

A spherical compressor, hemispherical technology, applied in the direction of mechanical equipment, machine/engine, swing piston machinery, etc., can solve the problems of increasing manufacturing and operating costs, spherical compressor stuck, piston rotation, etc., to achieve a small number of parts , simple structure and low machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] One, the first embodiment:

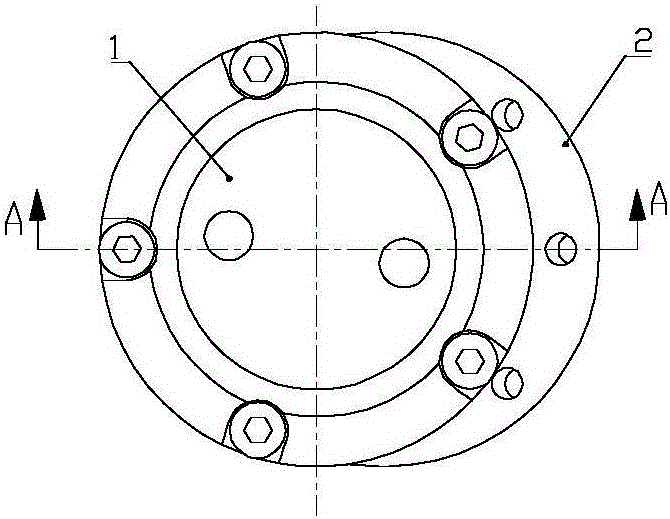

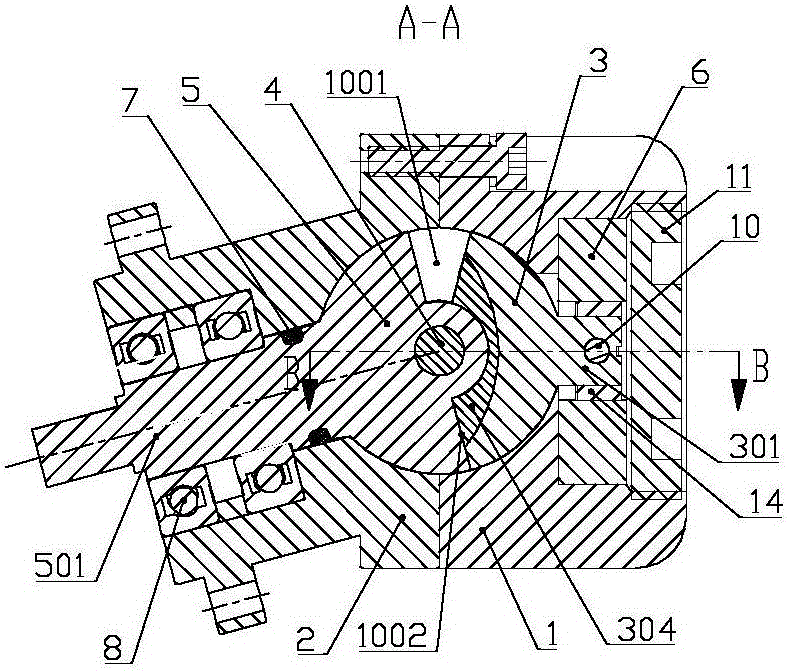

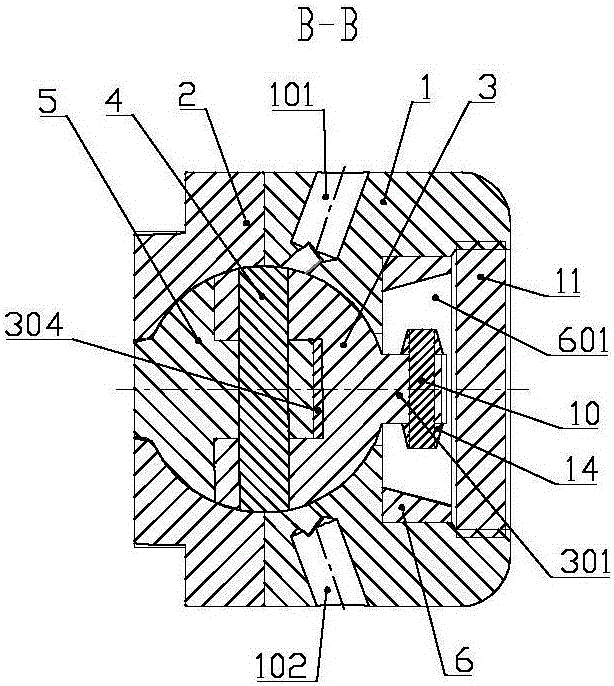

[0052] Figure 1 to Figure 13 Shown is the accompanying drawing of the first embodiment of the patent, as Figure 1 to Figure 8 As shown, the spherical compressor described in this patent includes a cylinder head 1, a cylinder body 2, a piston 3, a center pin 4, a turntable 5, etc., the cylinder body 2 and the cylinder head 1 have a hemispherical inner cavity, and the cylinder body 2 and the cylinder head 1 The casing of a spherical compressor with a spherical inner cavity is formed by screw fixing connection; an intake channel 103, an exhaust channel 104 and a piston shaft hole 105 are arranged on the inner spherical surface of the cylinder head 1; Through the turntable shaft hole 201 outside the cylinder, one side of the turntable shaft hole 201 is connected to the spherical inner cavity, and the other side is provided with a bearing seat hole, which is coaxial with the turntable shaft hole 201; the piston shaft hole 105 and the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com