A casing condenser

A condenser and sleeve type technology, which is applied to the field of sleeve type condensers for air source heat pump devices, can solve the problems of restricting water flow, extending the exchange path, and bulky condenser volume, so as to achieve increased flow and long heat exchange distance. , The effect of preventing insufficient heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

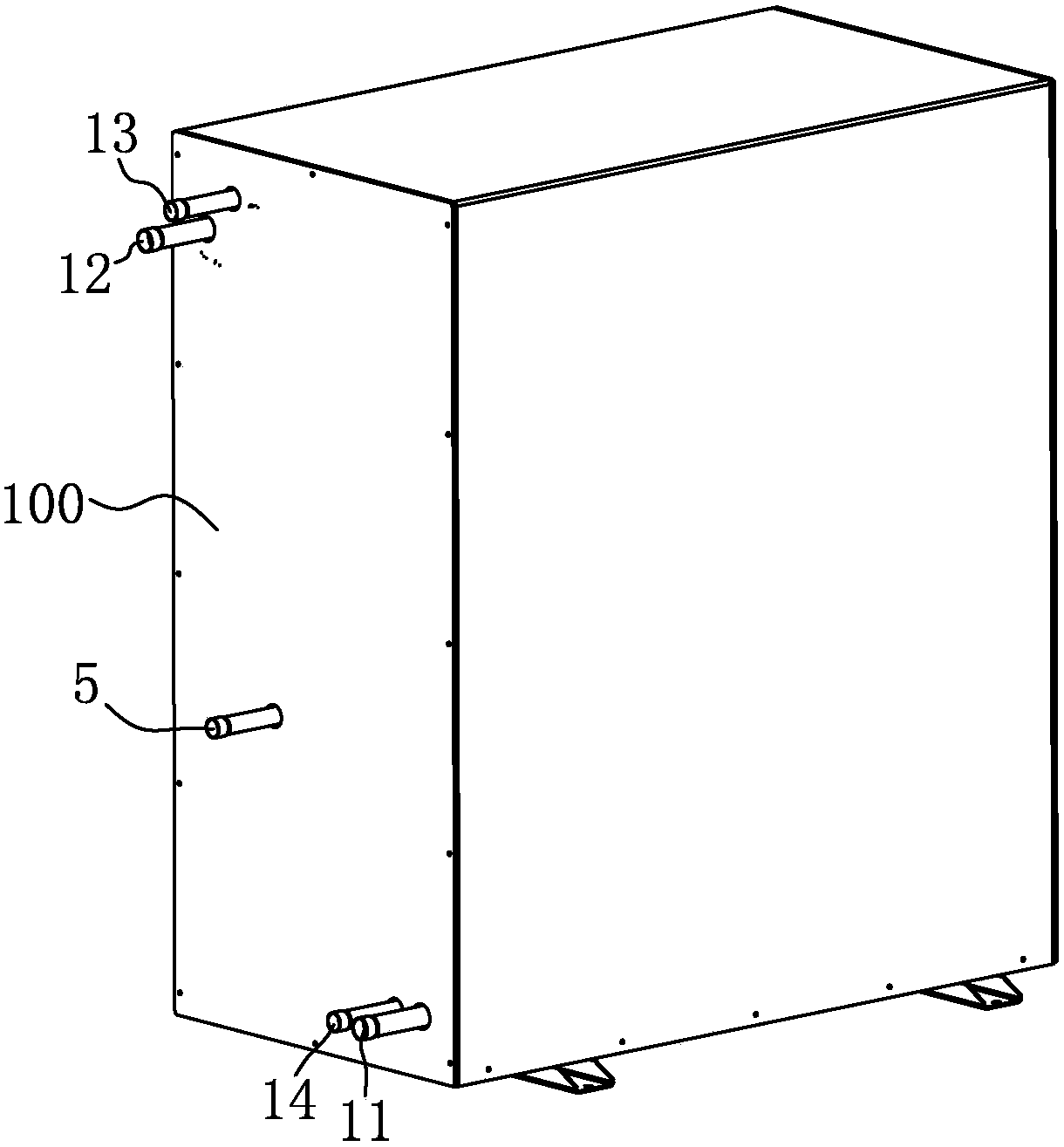

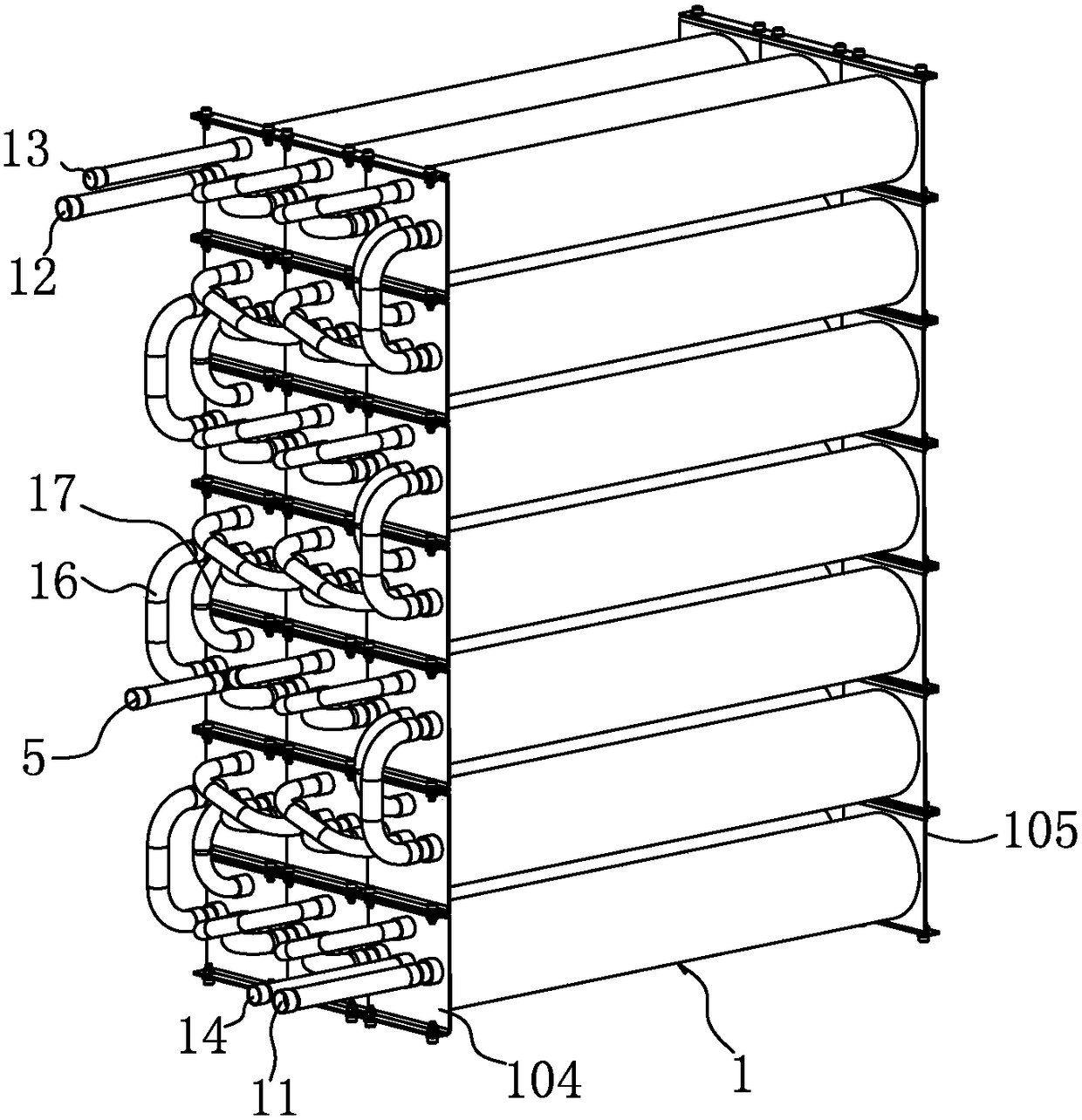

[0029] See Figure 1-6 As shown, the present invention is a casing condenser, which is composed of a plurality of condenser units 1 connected in series, and these condenser units 1 are neatly installed in the cabinet body 100 in an array.

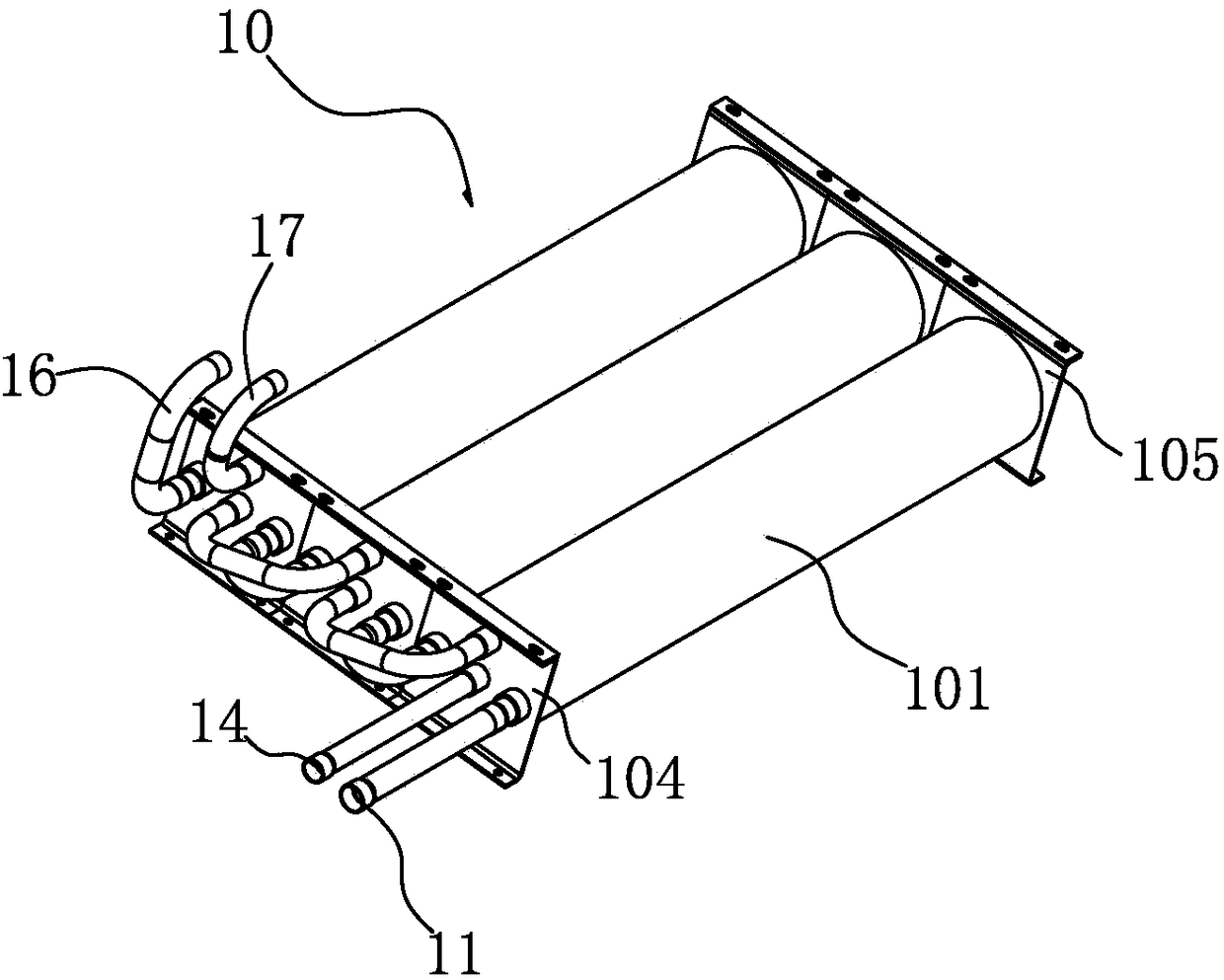

[0030] see Figure 2-5 As shown, the condenser unit 1 has a water inlet 11, a water outlet 12, a refrigerant inlet 13 and a refrigerant outlet 14, and a mutually isolated tube-side channel and a shell-side channel are formed in each condenser unit 1. The tube-side channel communicates with the water inlet 11 and the water outlet 12; the shell-side channel communicates with the refrigerant inlet 13 and the refrigerant outlet 14.

[0031] The condenser unit 1 includes: a tubular shell 101, in which at least two parallel and coiled water pipes are arranged. A front cover 104 and a rear cover 105 are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com