Automatic gram weight detecting and adjusting system for producing needled non-woven products

An automatic detection and adjustment system technology, applied in control/regulation systems, non-electric variable control, weighing equipment for materials with special properties/forms, etc., can solve problems such as uneven mixing of acupuncture machines, and achieve automation strength High, improve production efficiency, ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

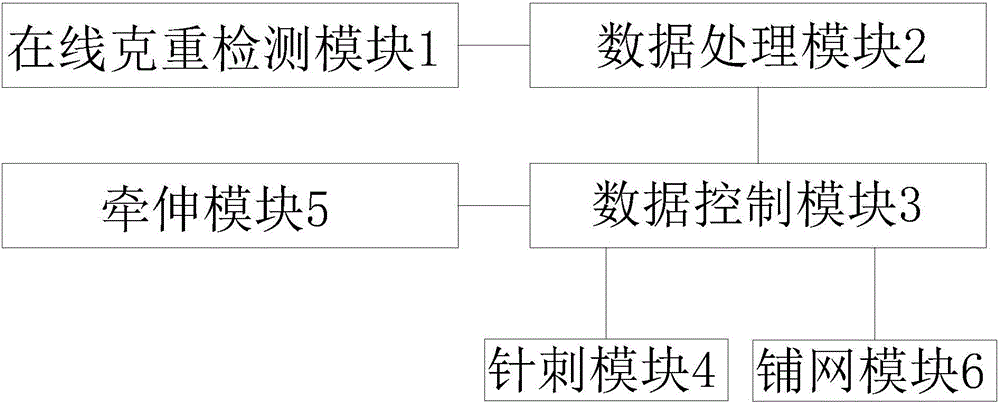

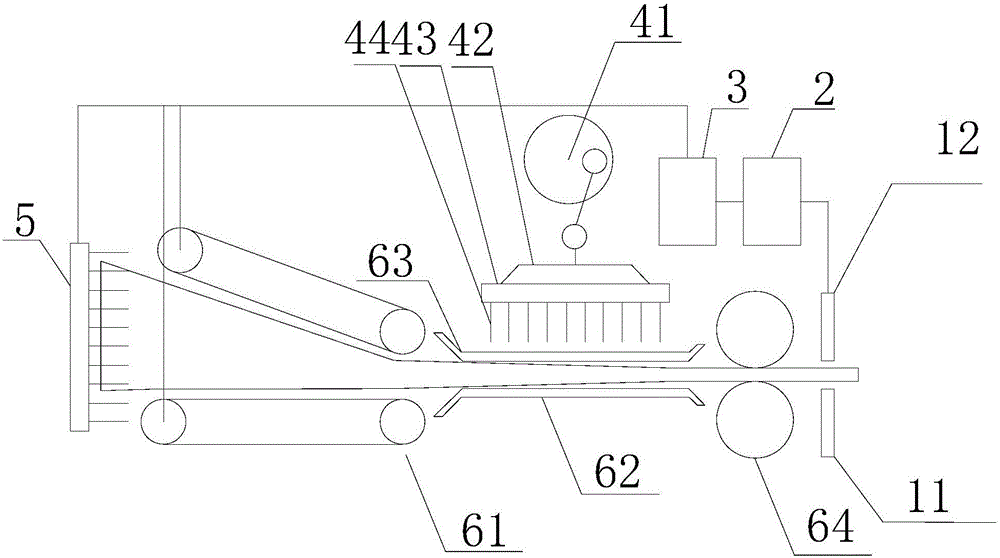

[0021] like Figure 1-2 As shown, the present invention includes a previous grammage detection module 1, a data processing module 2, a data control module 3, an acupuncture module 4, a drafting module 5, and a web laying module 6, and the online grammage detection module 1 is located in the web laying module 6 The rear end of the grammage detection module 1 includes a ray emitting part 11 and a ray receiving part 12, and the ray emitting part 11 and the ray receiving part 12 are respectively located at the bottom of the fiber net after acupuncture. The drafting module 5 is located at the front end of the web laying module 6, and when the fiber web needs to be drawn, the drafting module 5 and the web laying module 6 cooperate to stretch the fiber web.

[0022] The ray receiving part 12 is connected with the data processing module 2, and will process the real-time thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com