550-DEG C high-temperature metal material electromagnetic ultrasonic flaw detection method and device

A metal material, electromagnetic ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, and analysis materials, etc., can solve the problems of few reports, achieve high detection accuracy and real-time performance, high conversion efficiency, The effect of reliable high temperature flaw detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described on the front side in conjunction with the accompanying drawings.

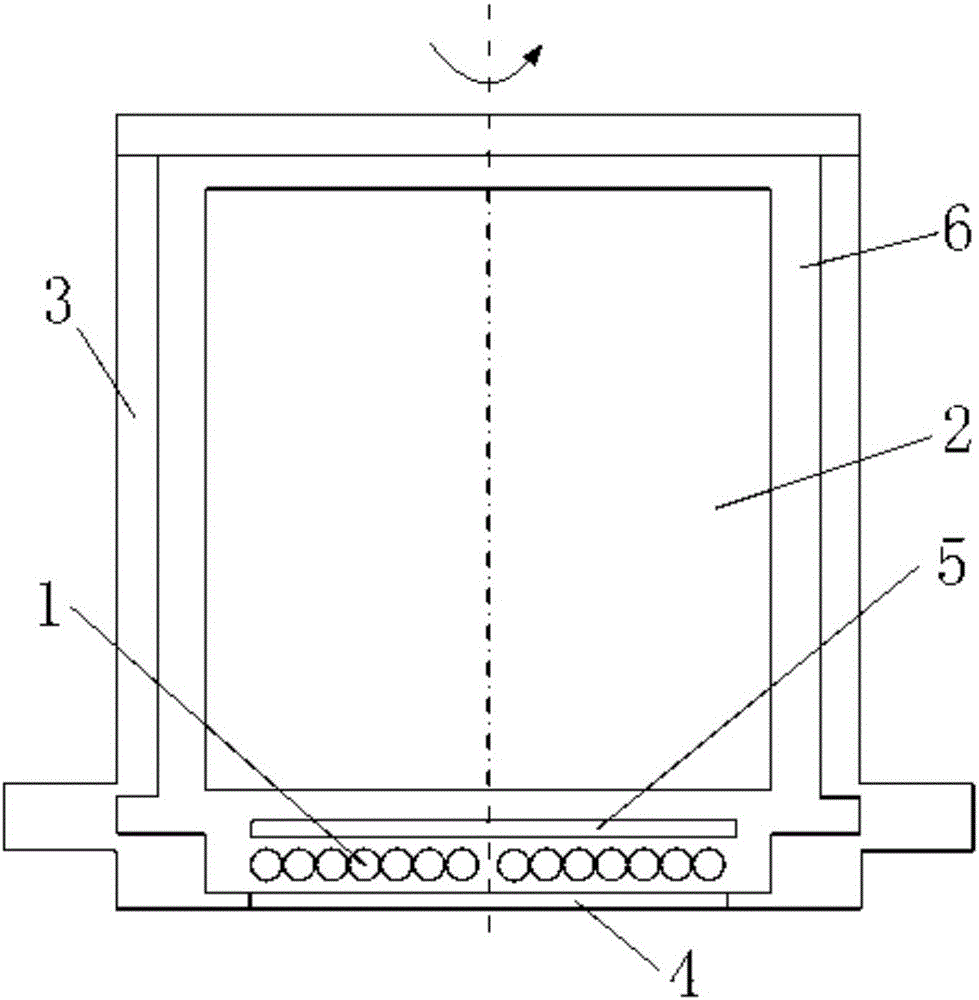

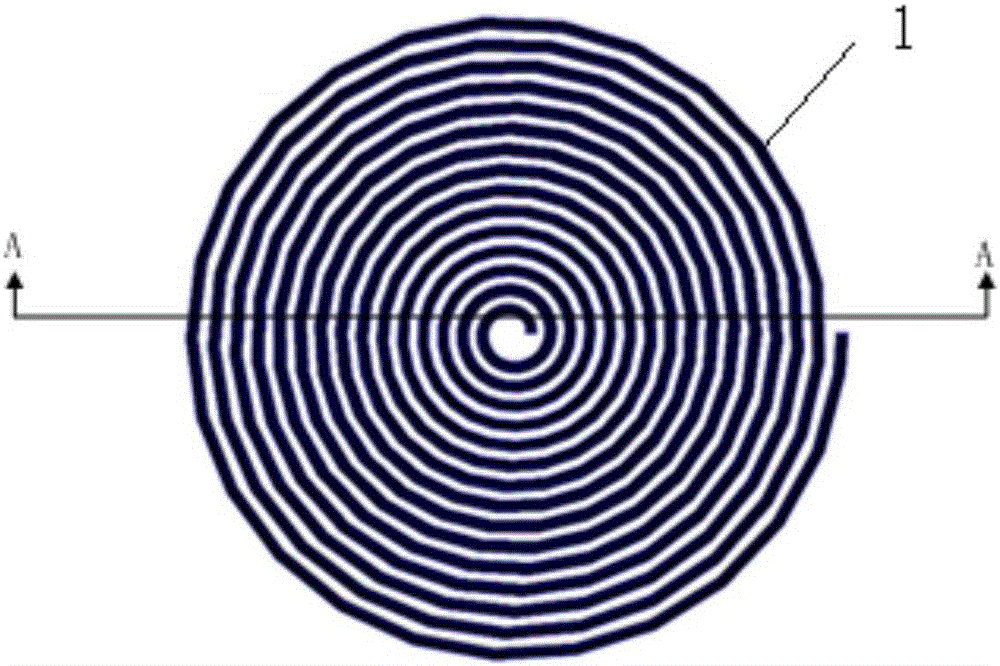

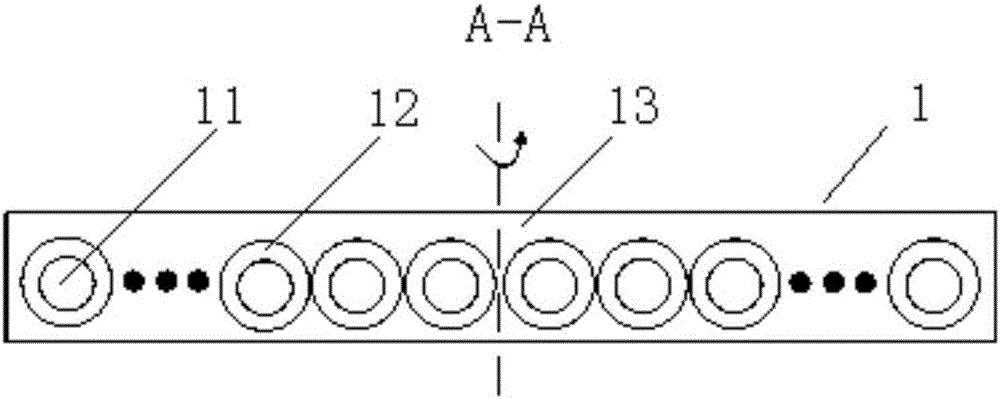

[0034] see figure 1 , figure 2 and image 3 , a device for implementing the electromagnetic ultrasonic body wave flaw detection method for metal materials at a temperature of 550°C, including a high-temperature electromagnetic ultrasonic probe. The structure of the high-temperature electromagnetic ultrasonic probe is: a ceramic coil 1, a copper plate 5 and a high-temperature-resistant permanent magnet 2 pass through a first ceramic adhesive 6 Pouring in the brass shell 3 , the copper plate 5 is between the ceramic coil 1 and the high temperature resistant permanent magnet 2 , and the corundum sheet 4 outside the ceramic coil 1 is provided at the working end of the brass shell 3 .

[0035] Preferably, the direction of the coil wire of the ceramic coil 1 is perpendicular to the direction of the bias magnetic field provided by the high temperature resistant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com