Heat-dissipation type copper bar

A heat-dissipating, copper-bar technology, used in conductors, insulated cables, electrical components, etc., can solve the problems of wasting electric energy, easily causing failures, and poor heat dissipation, shortening installation time, improving heat dissipation efficiency, and achieving high overall strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

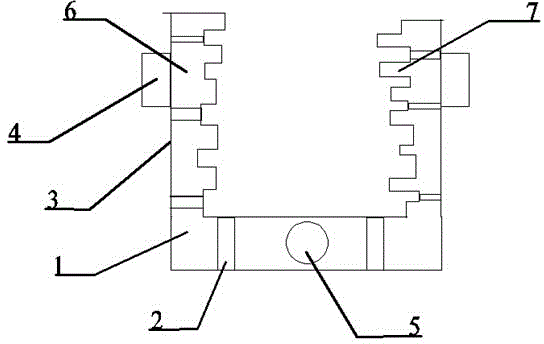

[0019] A heat-dissipating copper bar, which has a copper bar body 1, the cross section of the copper bar body 1 is a U-shaped structure, the surface of the copper bar body 1 is provided with a number of heat dissipation through holes 2, and the surface of the copper bar body 1 is coated with oxidation-resistant Membrane 3.

Embodiment 2

[0021] Example 2 as figure 1 As shown, it is improved on the basis of Example 1, and the surface of its copper bar body 1 is coated with an oxidation-resistant film layer 3 . Protect copper bars from oxidation. At the same time, the wear resistance is increased, the service life of the copper bar is extended, and the cost is reduced.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1, and two silver-plated protrusions 4 are provided on the side of its copper bar body 1 . Silver-plated material increases conductivity, reduces resistance, and increases power. At the same time, it is suitable for occasions with special shape requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com