DC load isolation switch

A technology of isolating switch and DC load, applied in the field of DC switch appliances, can solve the problem of inability to meet the breaking capacity requirements of DC traction power supply system, and achieve the effect of light weight, convenient installation and maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

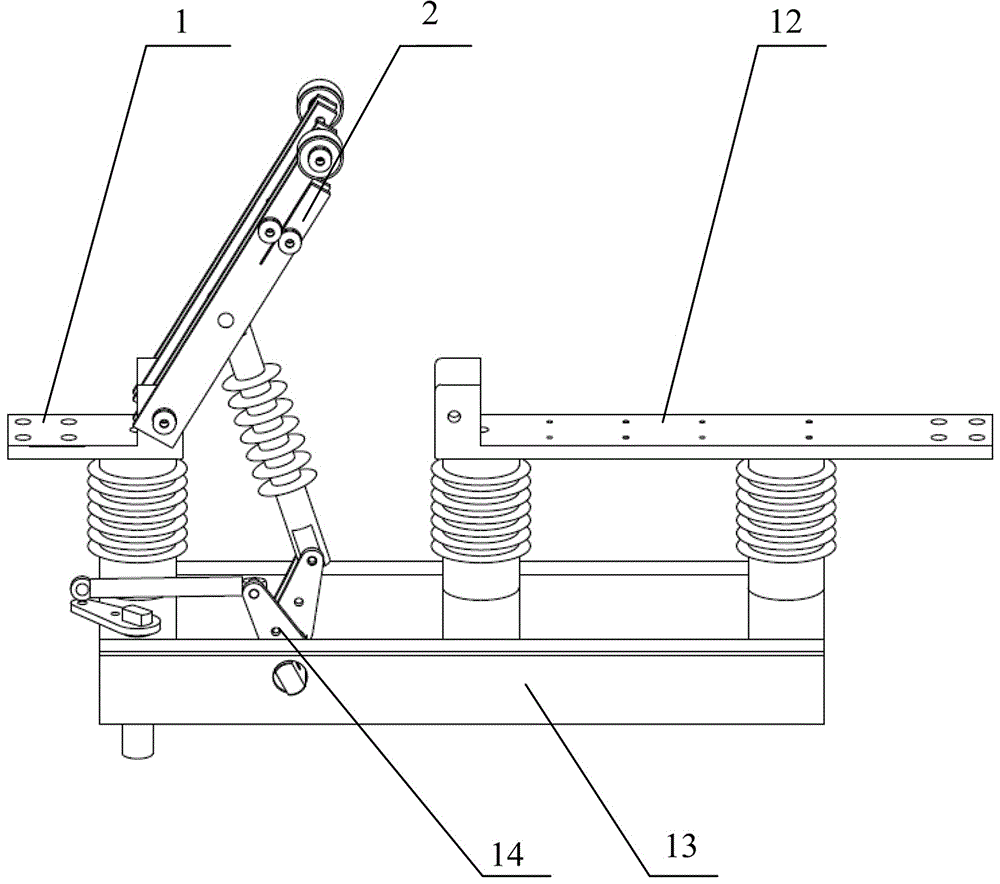

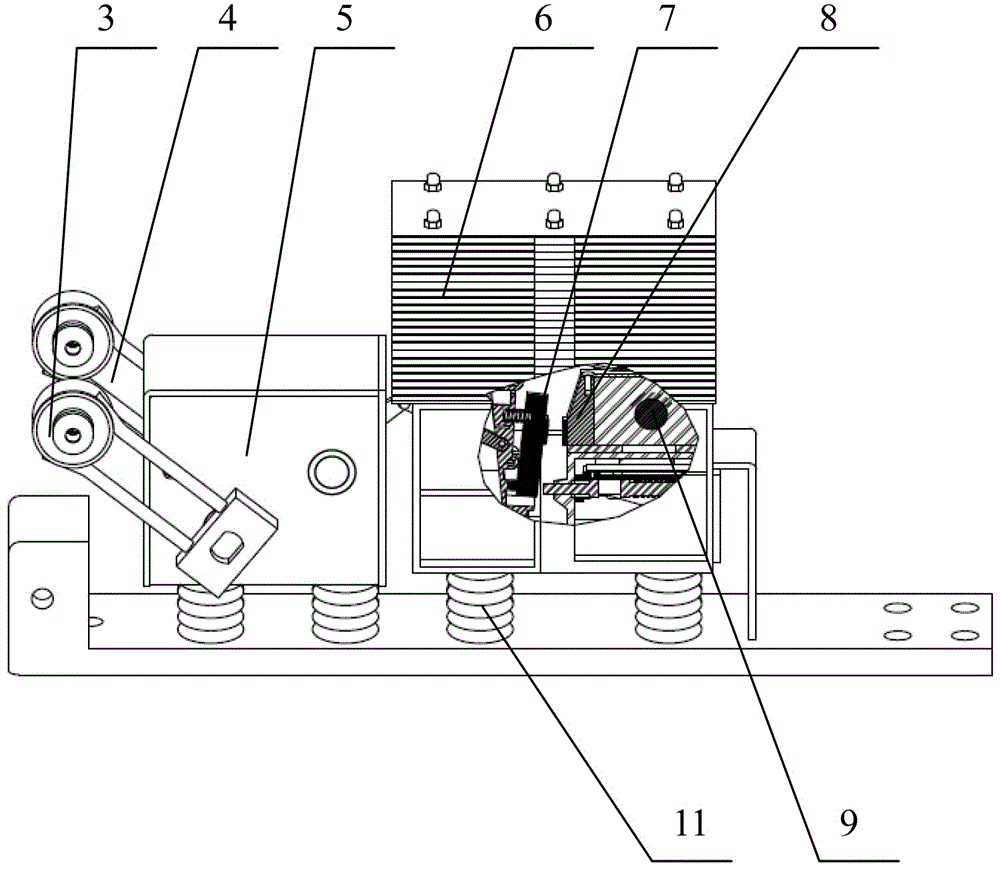

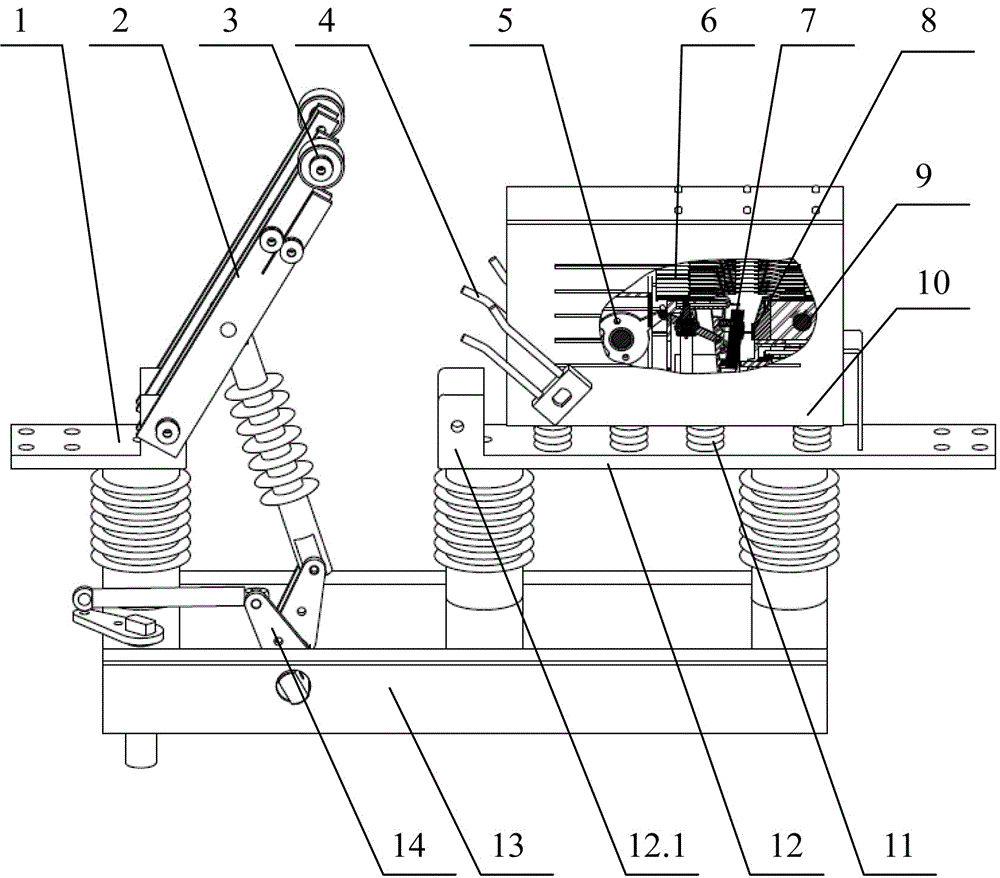

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] refer to Figure 1 to Figure 4 As shown, the present invention discloses a DC load disconnector, which is composed of a disconnector installed on an insulating support base 13 as a main switch and a load switch as an arc switch. The disconnector includes a connecting insulating support The moving contact busbar 1 of the base 13 and the crankshaft connecting rod mechanism 14, the crankshaft connecting rod mechanism 14 is connected with an insulating operating rod, the moving contact busbar 1 is movably connected with an isolating knife 2, and the isolating knife 2 consists of two sets of copper bars Formed side by side, the static contact 12.1 can be clamped in the middle and separated and closed in a sliding manner. The isolation knife 2 and the static contact busbar 12 are made of red copper, which improves the electrical conductivity and reduces the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com