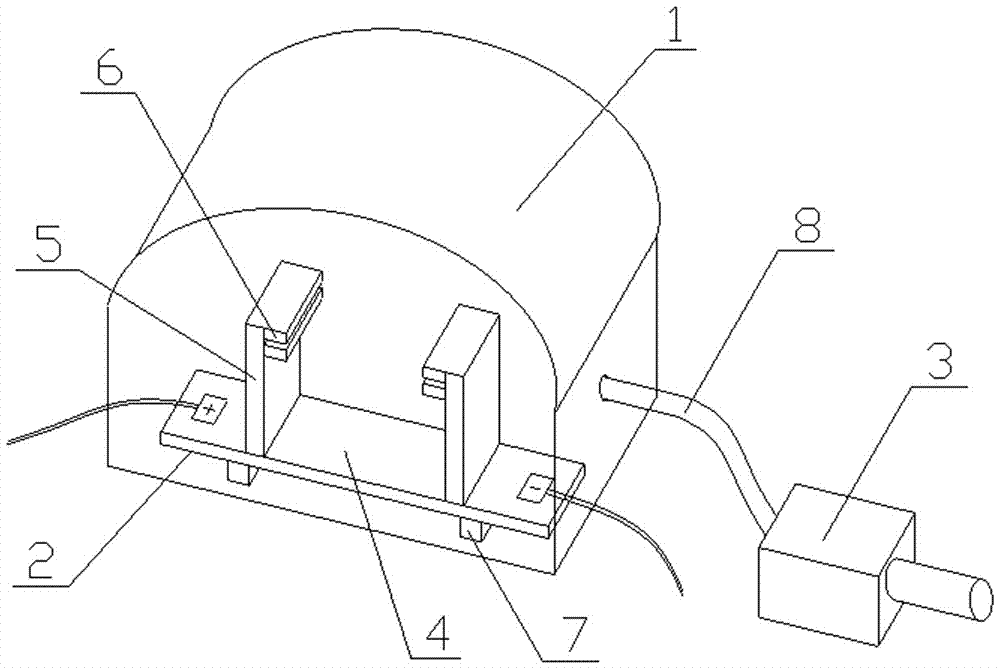

A vacuum evaporation device and a method for preparing an organic electroluminescent device using it

A technology of luminescence and evaporation, which is applied in the direction of vacuum evaporation plating, electric solid devices, electrical components, etc., can solve the problems of long time and high cost of evaporation, and achieve shortened time required for device preparation and high flatness , The effect of facilitating large-scale industrial manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

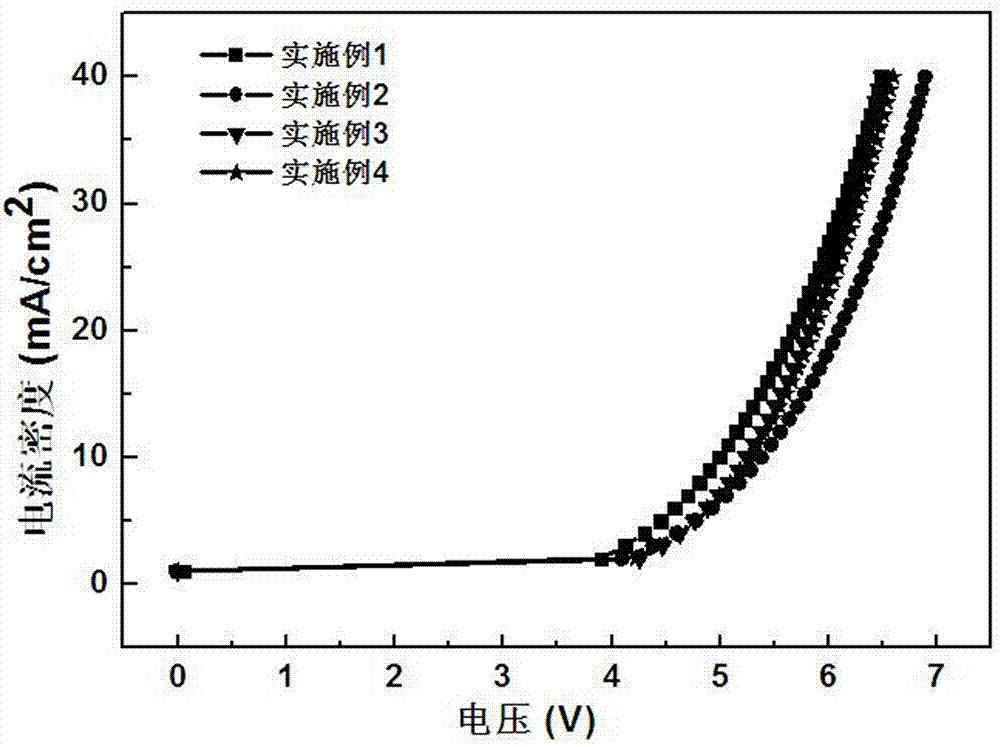

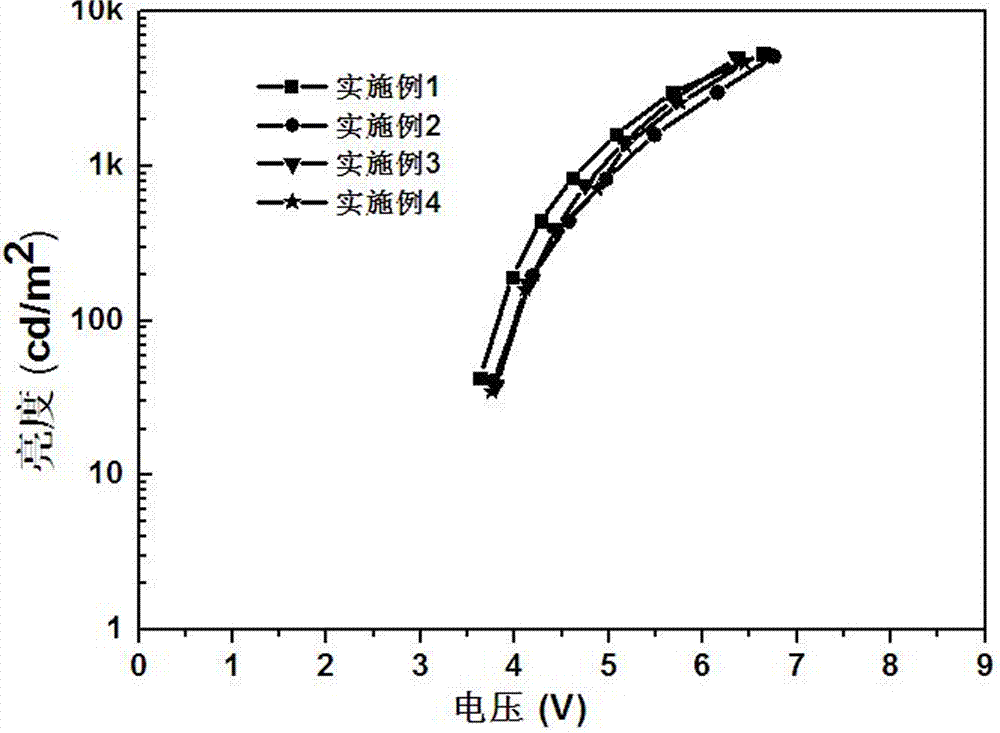

Embodiment 1

[0032] A method for preparing an organic electroluminescent device using a vacuum evaporation device, the method comprising the steps of:

[0033] Step 1: The ITO glass substrate is ultrasonically cleaned with acetone, ethanol and distilled water, then rinsed with distilled water and dried, then subjected to ozone treatment, and then spin-coated or scraped or ink-jet printed a layer of PEDOT on the ITO glass substrate : PSS, and then annealed, the annealing temperature is 160 ℃, and the annealing time is 15 min;

[0034] Step 2: Dissolve TAPC in chloroform and let it stand for 1 hour to obtain solution A, wherein the concentration of solution A is 30 mg / mL;

[0035] The third step: ultrasonically clean the silicon substrate I with acetone, ethanol and distilled water successively, then rinse with distilled water and dry, and then apply solution A evenly on the silicon substrate by spin coating, scraping coating or inkjet printing Ⅰ surface, forming a thin film with a thicknes...

Embodiment 2

[0042] In Example 2, the method for preparing an organic electroluminescent device using a vacuum evaporation device is the same as that in Example 1, the difference being that the vacuum pump 3 is used to pump the pressure in the vacuum evaporation cover 1 to 0.1 in the fourth step and the seventh step. Pa.

Embodiment 3

[0044] In Example 3, the method for preparing an organic electroluminescent device using a vacuum evaporation device is the same as that in Example 1, the difference being that in the fourth step and the seventh step, a vacuum pump 3 is used to pump the pressure in the vacuum evaporation cover 1 to 1 Pa. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com