Lily back pressure microwave continuous drying device

A drying device, Lily's technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve problems affecting water overflow, reducing drying efficiency, affecting product quality, etc., to achieve quick and convenient disassembly and enhanced load bearing Ability, tension-relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with accompanying drawing, the present invention is described in further detail.

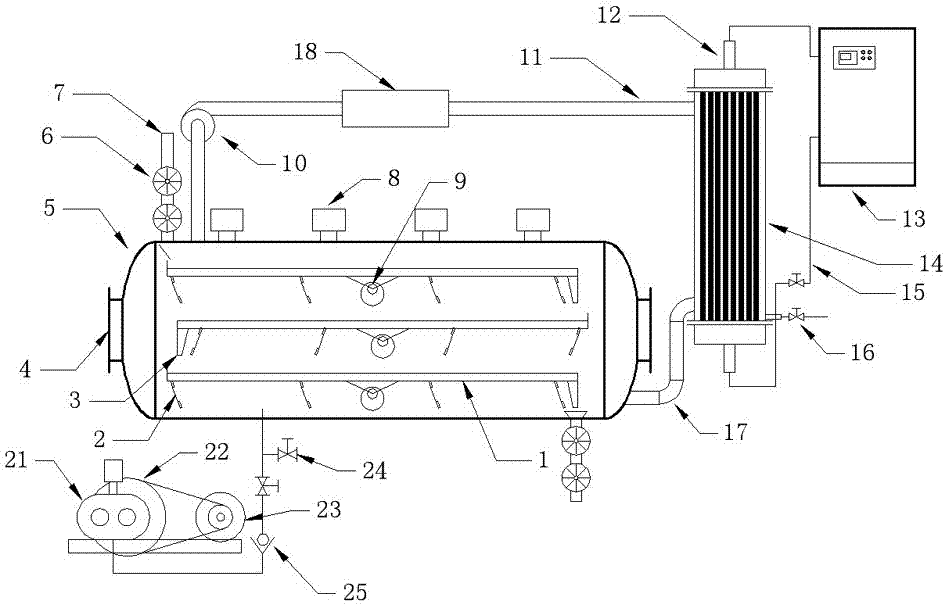

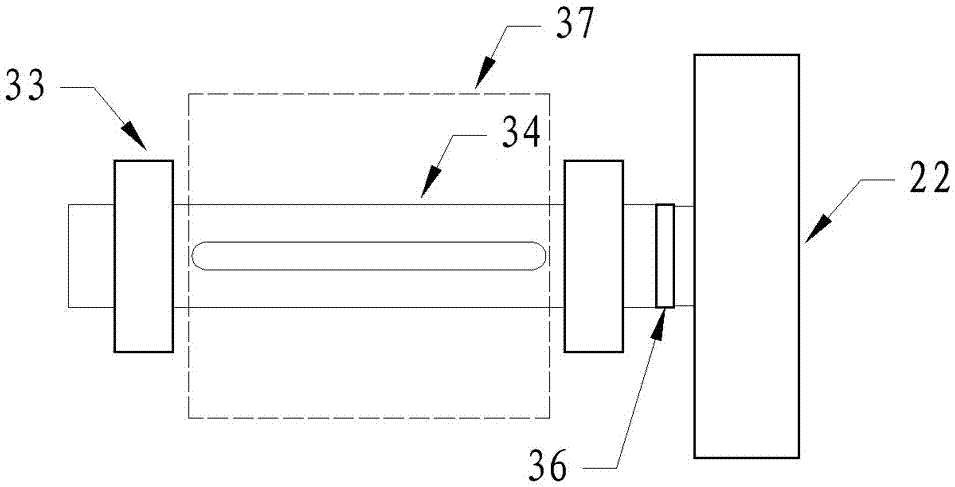

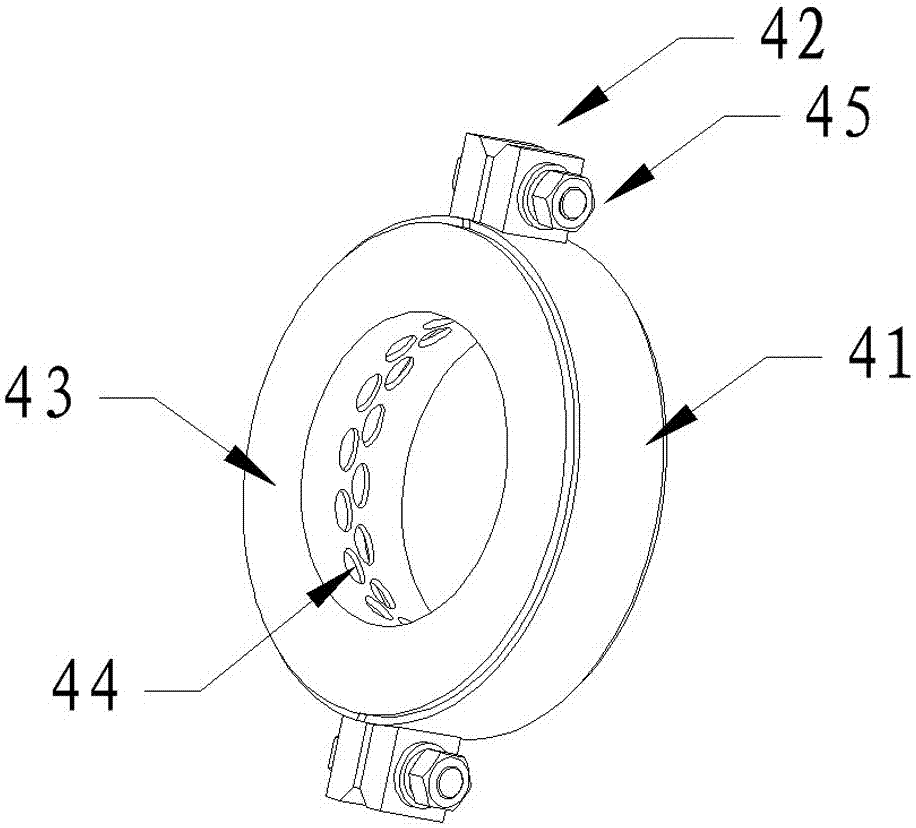

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown lily back pressure microwave continuous drying device includes a pressure tank body 5, and several microwave generators 8 are arranged on the upper part of the pressure tank body 5 and on the left and right sides; the pressure tank body is provided with a multi-layer vibration trough 1 and a vibration source 9; The lily is added from the feed port 7, and enters the pressure tank 5 through the two-stage feed valve 6 to isolate the air pressure, and gradually moves from left to right through the vibrating trough 1, and falls into the next layer of trough through the feed port 3 at the right end , layer by layer vibrating conveying whereabouts, and finally through the two-stage discharge valve to isolate the air pressure and discharge it out of the pressure tank 5; the compressed air pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com