Automatic air isolation device for feeding port of electric heating smelting furnace

The technology of feeding port and electric heating is applied in the field of continuous melting and continuous casting of oxygen-free copper rods by the upward-drawing method. The effect of fast, reducing labor intensity and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

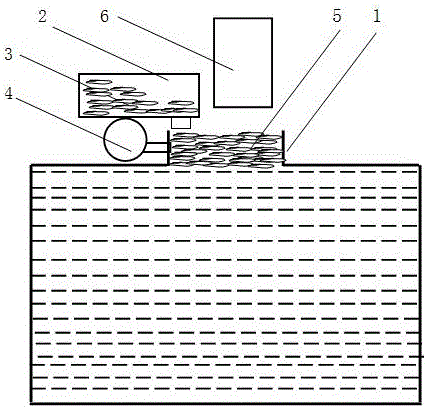

[0013] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0014] like figure 1 As shown, an electric heating melting furnace feeding port air automatic isolation device includes a charging port 1, a charcoal feeding machine 2 is arranged on the upper left side of the charging port 1, and a certain amount of charcoal 3 is stored in the charcoal feeding machine 2, and the charcoal 3 is cut into unequal lengths smaller than the diameter of the feed port, start the charcoal feeder 2, place the charcoal 3 in the feed port 1, make it evenly fill the feed port and become tightly covered Layer 5 of charcoal on top of melted copper water.

[0015] As a further improvement of the above technical solution, it also includes setting a charcoal thickness detector 4 on the left side of the feeding port 1, so as to add the charcoal 3 in time to ensure that the charcoal 3 always maintains a certain thickness.

[0016] Beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com