Pipeline pressure tapping machine capable of being remotely controlled

A pressurized hole opening and remote control technology, which is applied to pipes, branch pipelines, mechanical equipment, etc., can solve the problems of low output power of the spindle, cumbersome operation, and high price, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

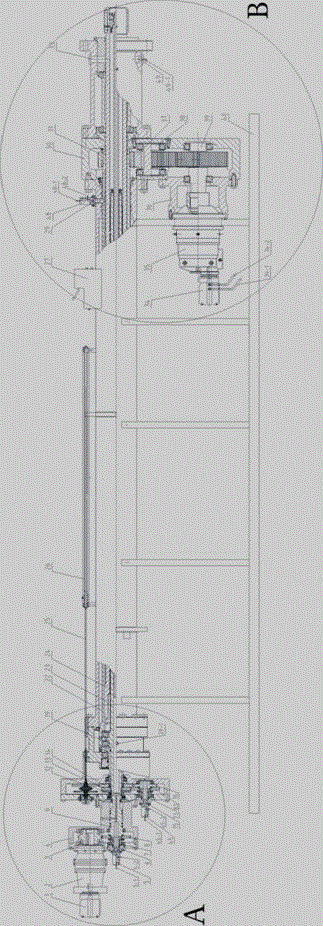

[0055] figure 1 It is a structural schematic view of the drilling machine of the present invention placed on the frame 40 .

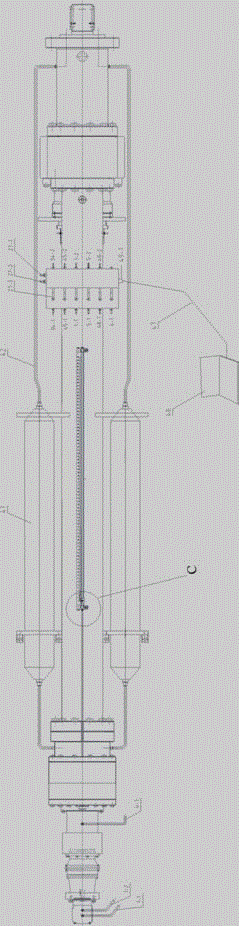

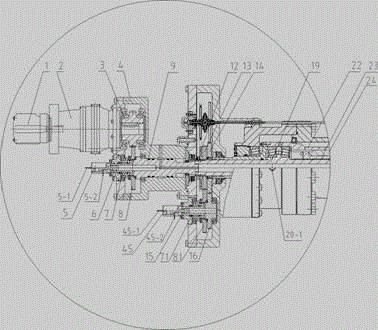

[0056] Such as Figure 1-Figure 5As shown, the present invention provides a remote-controllable pipeline pressure drilling machine, including a main body, a cutting feed drive device, a rotary drive device, an advance and retreat drive device, a hydraulic control device and a remote monitoring system; the main body Including drive sleeve 22, first lead screw 19, lead screw cover 23 and main shaft 24 installed in drive sleeve 22; Rotation and linear motion can be performed in the barrel 22; the screw sleeve 23 is fixedly installed in the upper inner hole of the main shaft 24; the first screw 19 is combined with the screw sleeve 23, and the screw sleeve rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com