Laser double beam welding equipment and method

A welding equipment and welding method technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as insufficient stability, poor welding wire filling effect, and insufficient welding quality, so as to improve repeatability and improve The effect of welding quality and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail, but the present invention is not limited to the scope of the described embodiments.

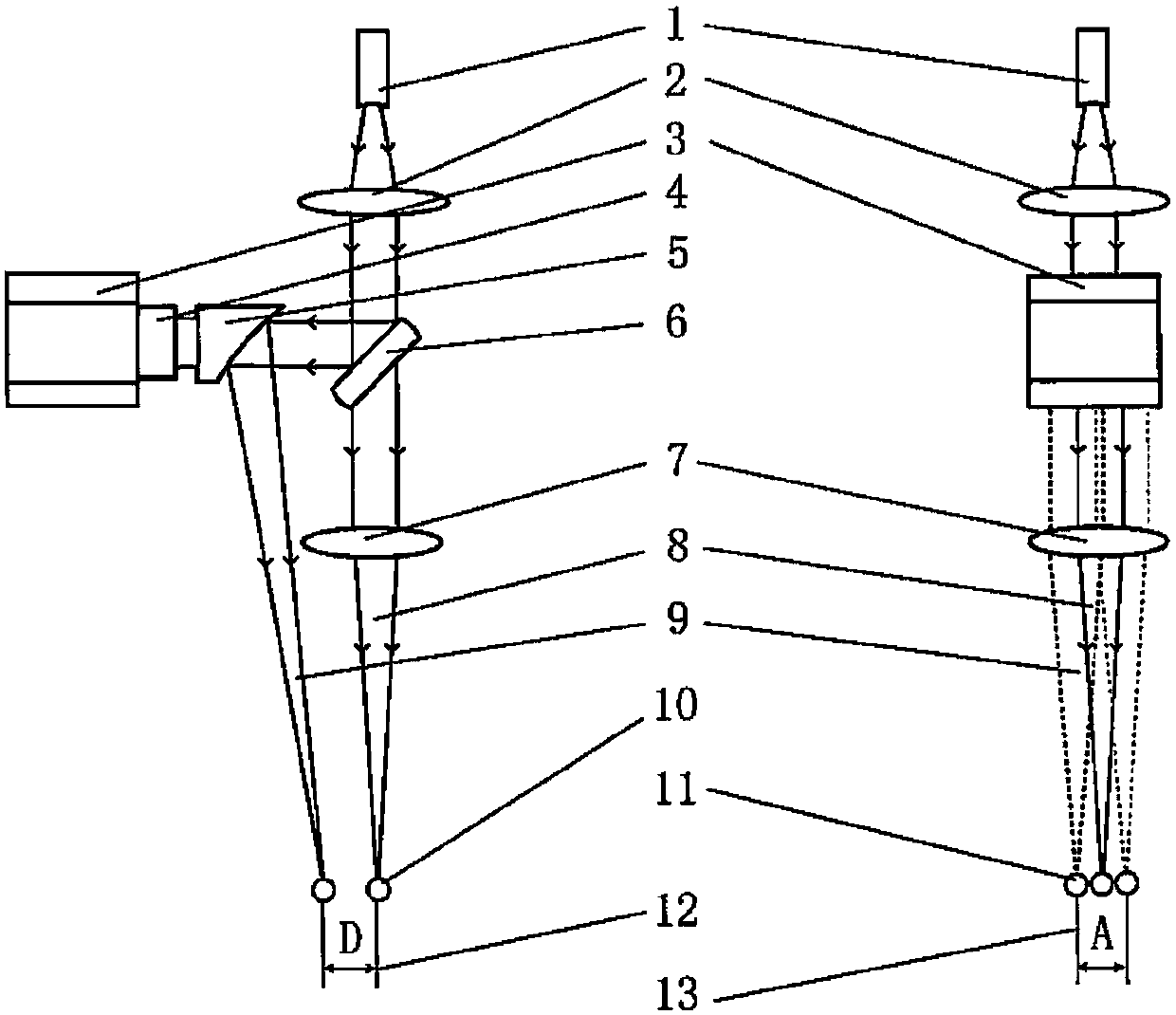

[0035] figure 1 The laser double-beam welding equipment of the present invention is shown.

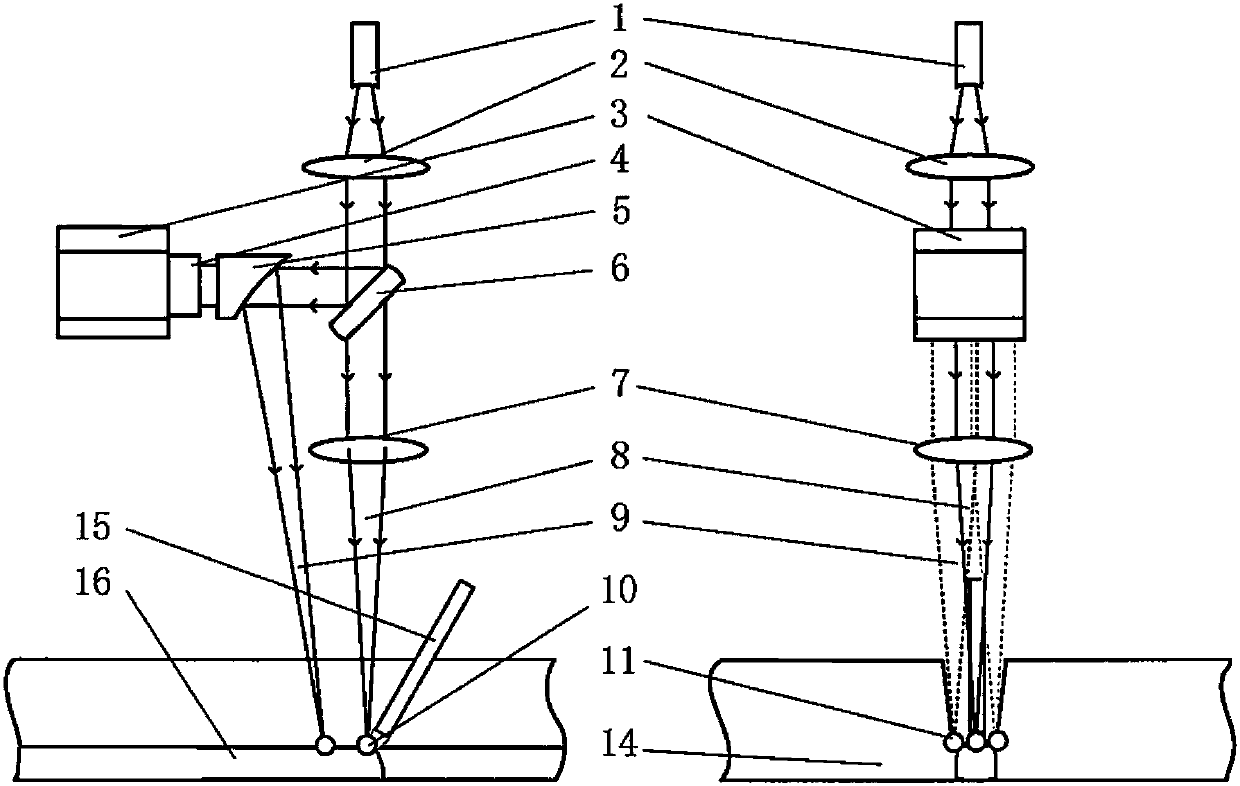

[0036] refer to figure 1 As shown, the laser double-beam welding equipment of the present invention includes a transmission fiber coupling interface 1 , a collimation system 2 , a laser scanning device, a beam splitter 6 and a convex lens 7 . Wherein the laser scanning device includes a stepping motor 3 , a retractable transmission shaft 4 and a reflective focusing mirror 5 .

[0037] The transmission fiber coupling interface 1 and the collimation system 2 are used to generate a collimated initial laser beam and transmit it to the beam splitter 6 . The beam splitter 6 is used to split the initial laser beam int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com