A tungsten pole position correction method for narrow-gap rotating arc gtaw based on deep learning algorithm

A deep learning and rotating arc technology, applied in neural learning methods, arc welding equipment, computing, etc., can solve problems such as sidewall failure to fuse, and achieve the effects of ensuring stability, improving stability, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

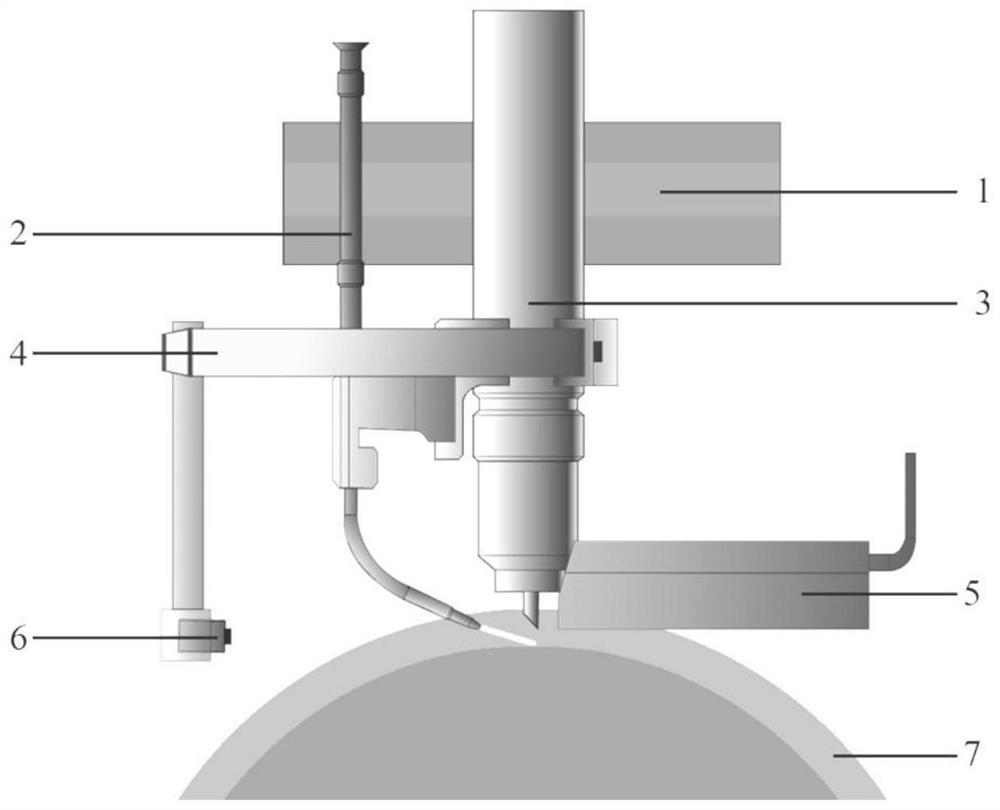

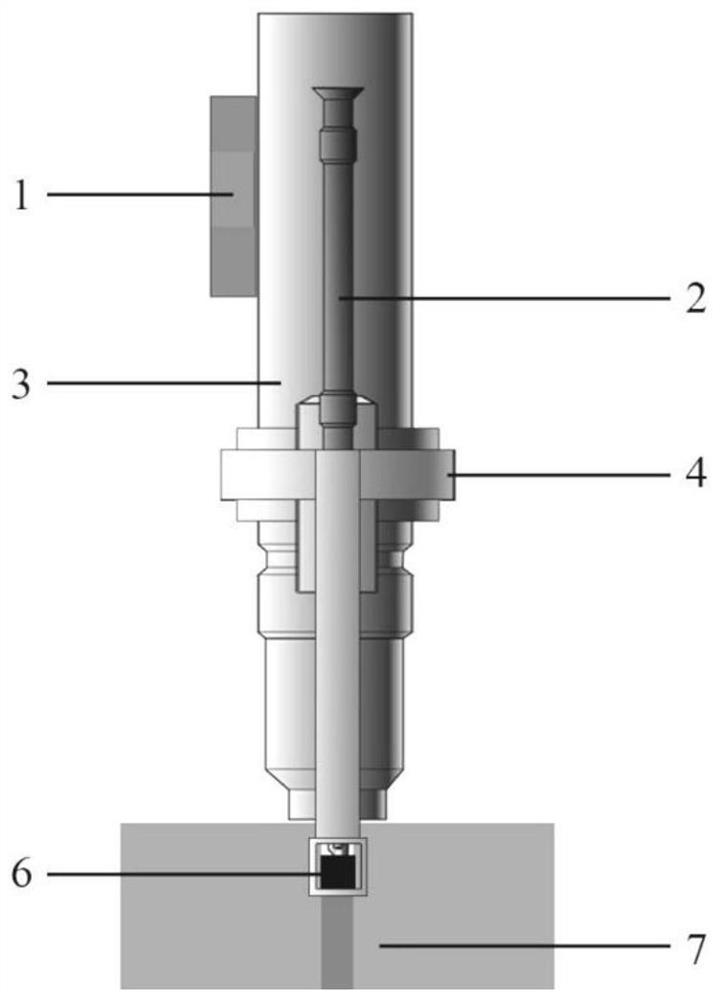

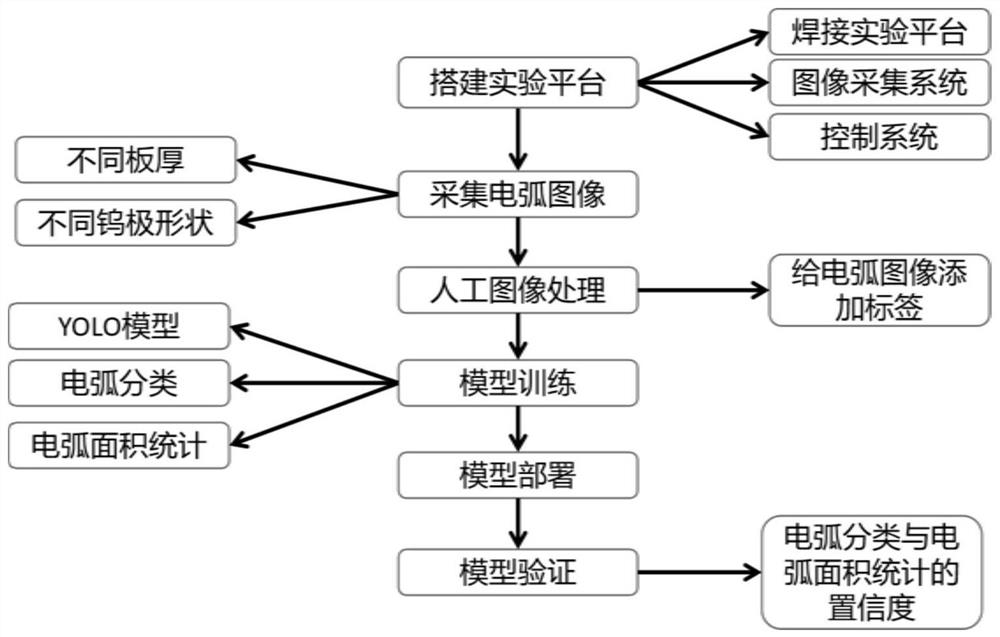

[0042] A method for rectifying the position of a tungsten pole of a narrow-gap rotating arc GTAW based on a deep learning algorithm, comprising a NAR-GTAW welding system, a visual image detection system, an image processing system, a communication system and a control system;

[0043] The NAR-GTAW welding system includes a NAR-GTAW welding power source, a PAW welding power source, a NAR-GTAW welding torch 3, a box-type chiller, a wire feeding device 2, an air supply device, a rear protective gas cover 5, and a collection and control system; The acquisition and control system described above includes a USB3.1 Gen1 expansion board and a PLC controller; the PLC controller controls the NAR-GTAW welding torch for position correction;

[0044] The visual image detection system includes a lens, a CCD camera 6, an optical filter, and a monitor;

[0045] The image processing system includes image processing hardware and image processing software; the image processing hardware is a comp...

Embodiment 2

[0058] A method for rectifying the position of the tungsten pole of a narrow-gap rotating arc GTAW based on a deep learning algorithm. The camera fixing frame 4 is fixed and moves with the movement of the welding torch along the moving carriage 1, which avoids the problem of unclear images caused by the change of the focal length due to the movement of the welding torch during the moving process, and is consistent with the horizontal direction of the welding platform. At an angle of 10° to 30°, it is beneficial to obtain a clear image of the welding arc.

Embodiment 3

[0060] A method for rectifying the position of the tungsten pole of a narrow-gap rotating arc GTAW based on a deep learning algorithm. 100FPS with a resolution of 640×640.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com