Bilateral rotary laser-TIG electric arc welding method and clamping tool for cross joint

A welding method, cross-shaped technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as undercut, affecting product mechanical properties, stress concentration, etc., to increase melting area and increase penetration efficiency , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

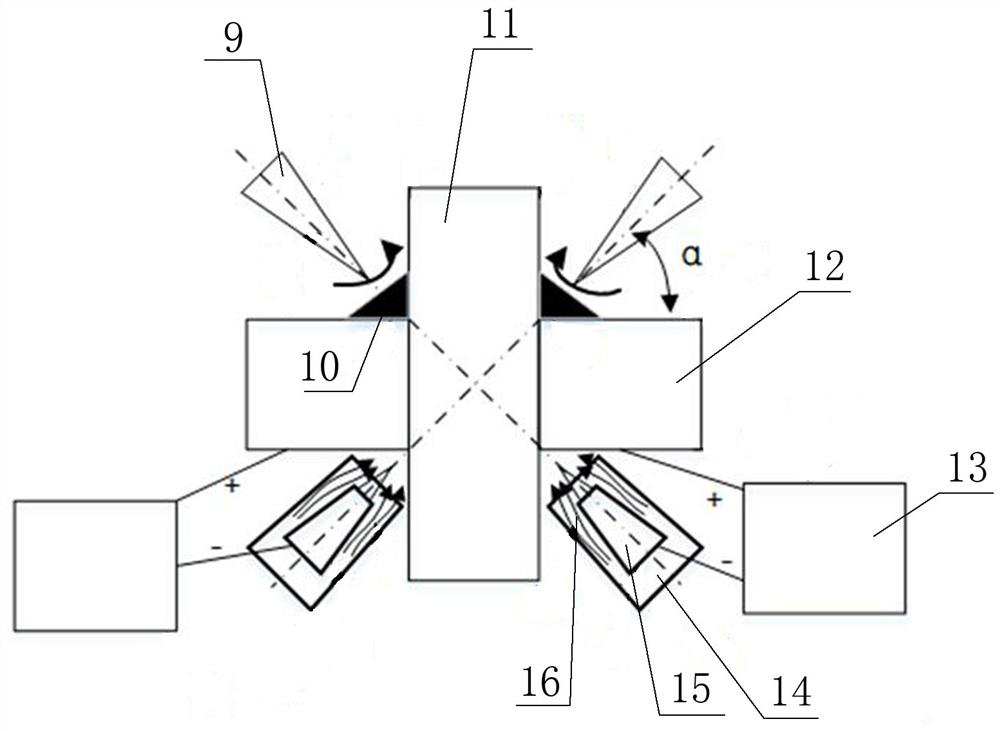

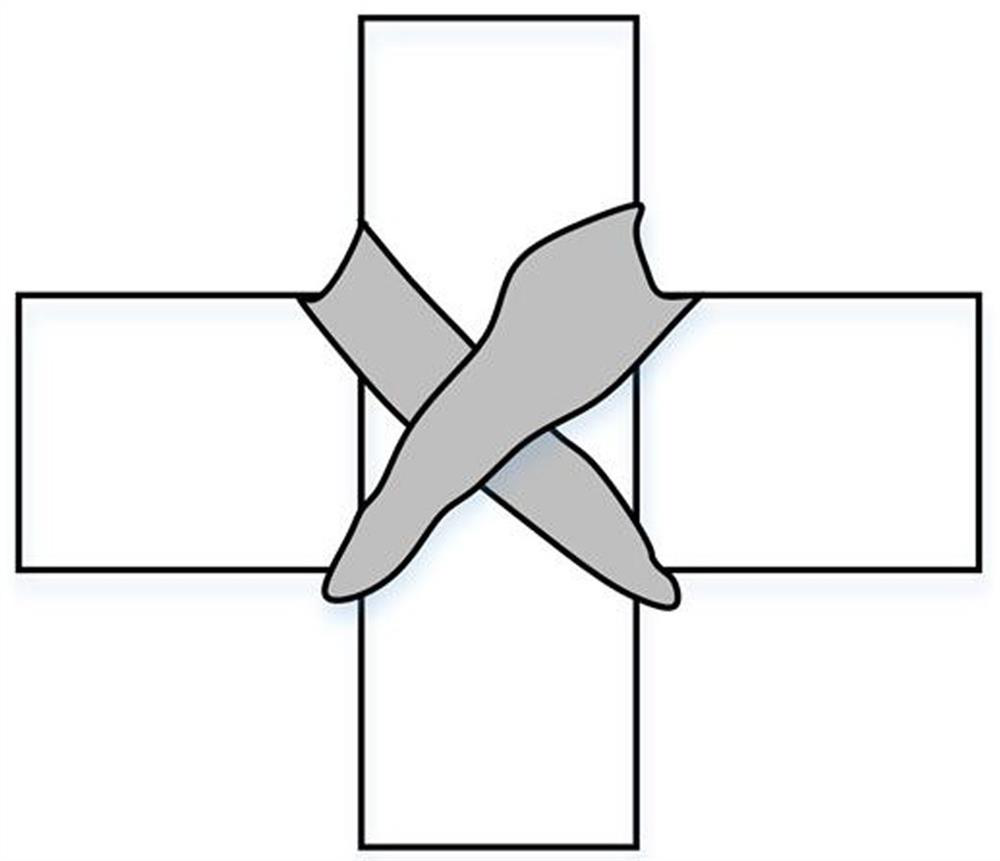

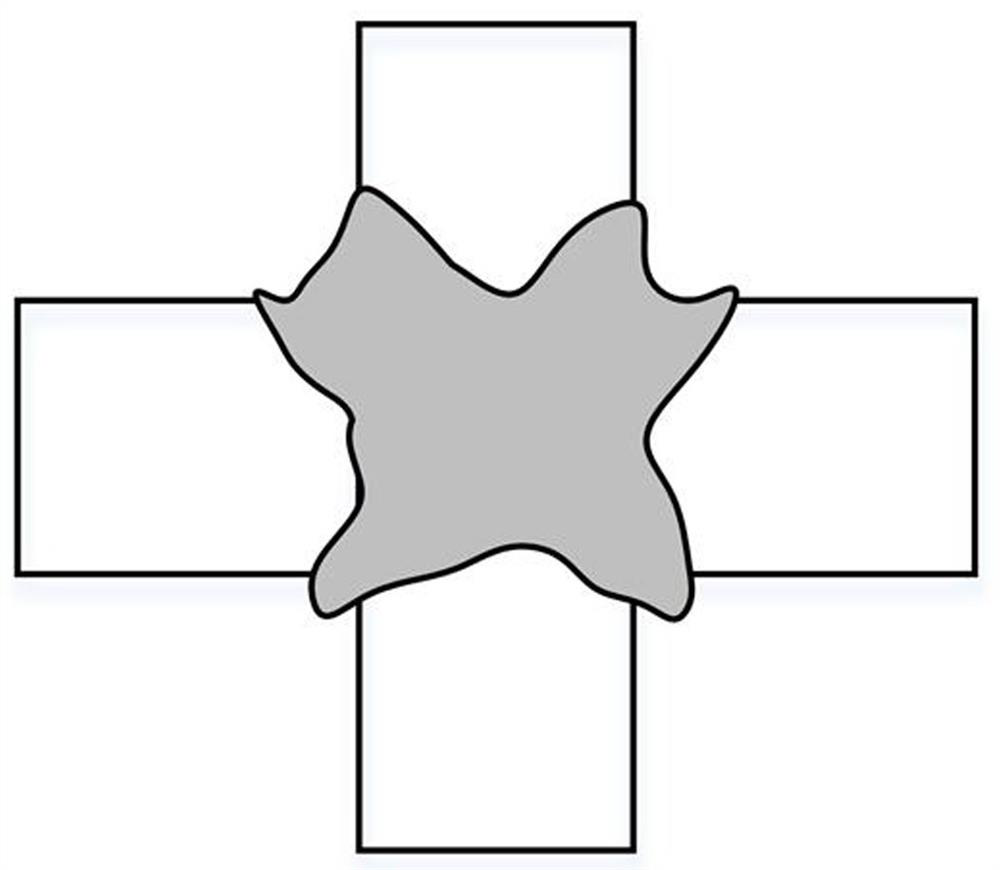

[0034] Such as figure 1 As shown, a double-sided rotating laser-TIG arc welding method of a cross-shaped joint of the present invention consists of two laser emitting heads arranged on both sides of the upper part of the cross-shaped joint and two TIG welding heads arranged on both sides of the lower part of the cross-shaped joint Welding torch 15 cooperates to weld the cross joint. The included angle α between the axis of the laser emitting head and the horizontal plane is 30-80°. The laser emitting head and the TIG welding torch 15 each rotate with a certain radius with a center line parallel to its own axis, and the laser emitting head and the TIG welding torch 15 at the diagonal position remain coaxial. Before welding, the metal powder 10 matched with the laser beam 9 emitted by the laser emitting head is preset on both sides of the upper part of the cross-shaped joint. Liquid metal lifts. The TIG welding gun 15 is coaxially distributed in the shielding gas nozzle 14 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com