Pipeline intersecting line projecting device and projecting method

A projection device and intersecting line technology, which is applied in measuring devices, active optical measuring devices, surveying and navigation, etc., can solve the problems of low stakeout accuracy of intersecting lines, strong pertinence of templates, troublesome follow-up processes, etc., and achieve reasonable design , improve the precision of stakeout, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

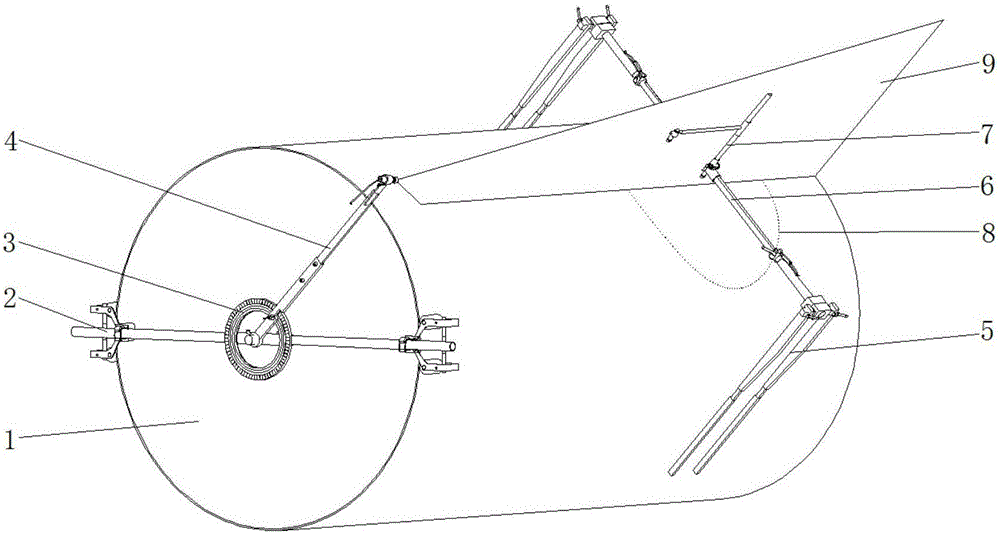

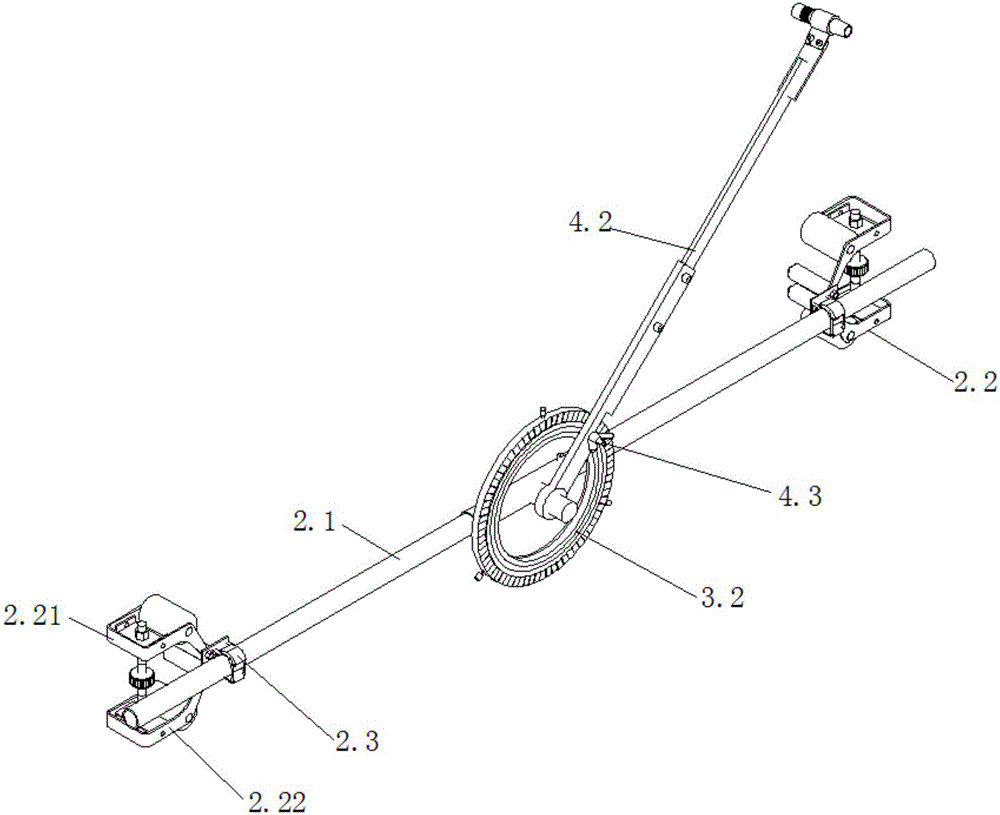

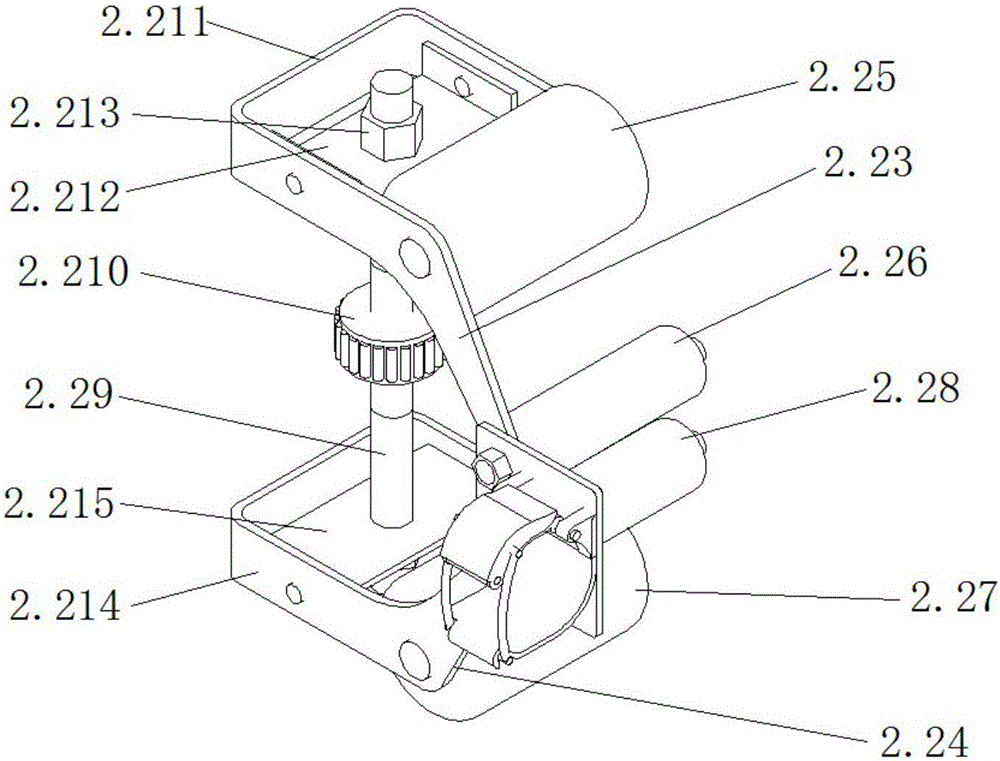

[0033] In pipeline installation engineering, multiple pipelines intersect to form intersecting lines. During installation, after the main pipe 1 is positioned, the large sample of the intersecting line 8 is released accurately earlier, and then the intersecting branch pipes are welded with the main pipe 1. Such as figure 1 As shown, the present invention provides a pipeline intersecting line pay-off system, the system includes a pipeline axis pay-off device and a pipeline intersecting line projection device, the pipeline axis pay-off device is installed on the end face of the main pipe 1, according to the branch pipeline At the intersection position with the main pipeline 1, the axis of the branch pipeline is set out on the outer wall of the main pipeline 1; the pipeline intersecting line pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com