Large rotary disk type stone machining equipment

A stone processing and large turntable technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of single processing procedure, large occupation area, low work efficiency, etc., to reduce the overall volume and occupy a small area. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

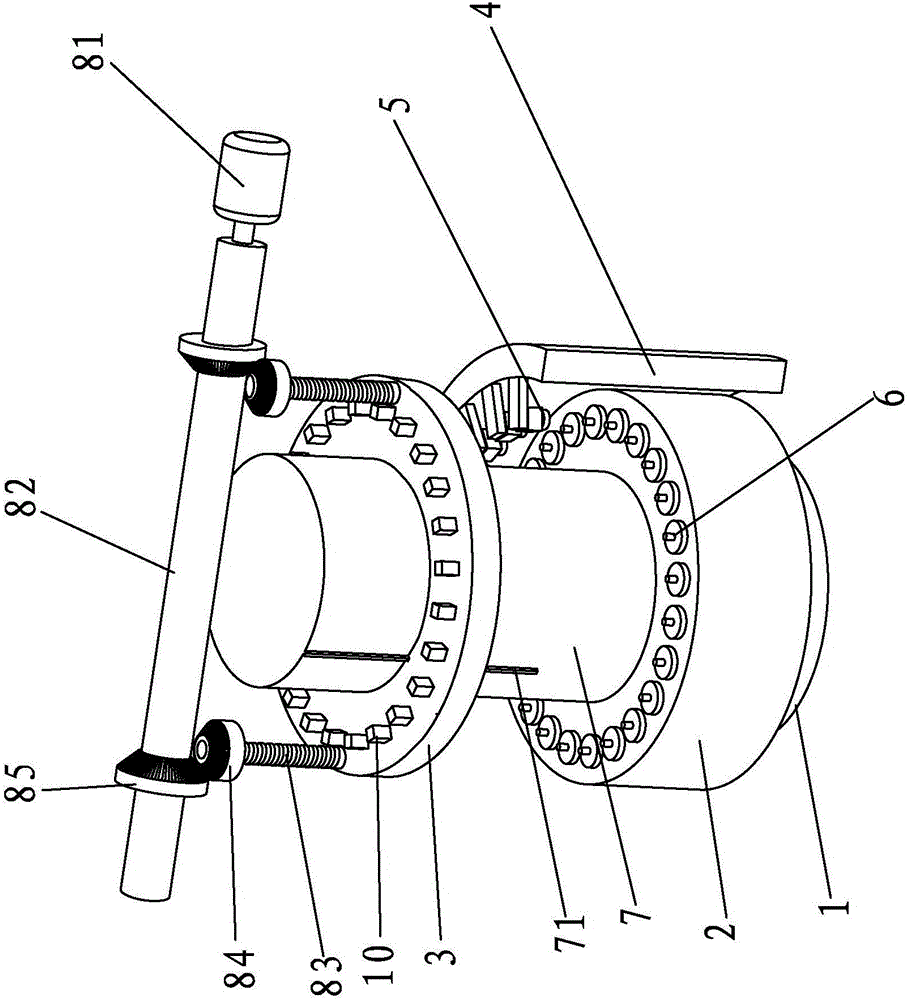

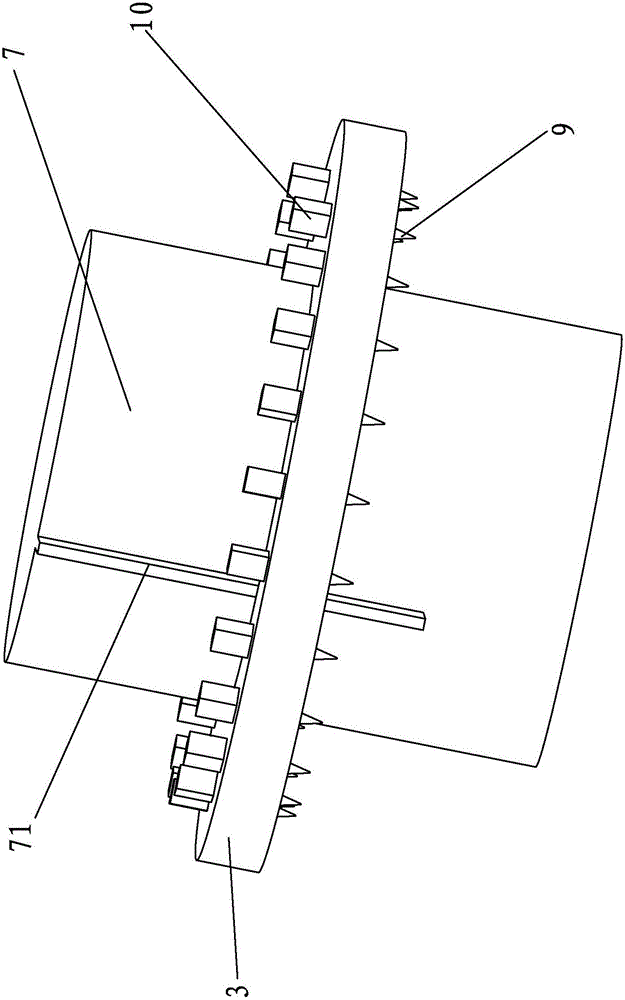

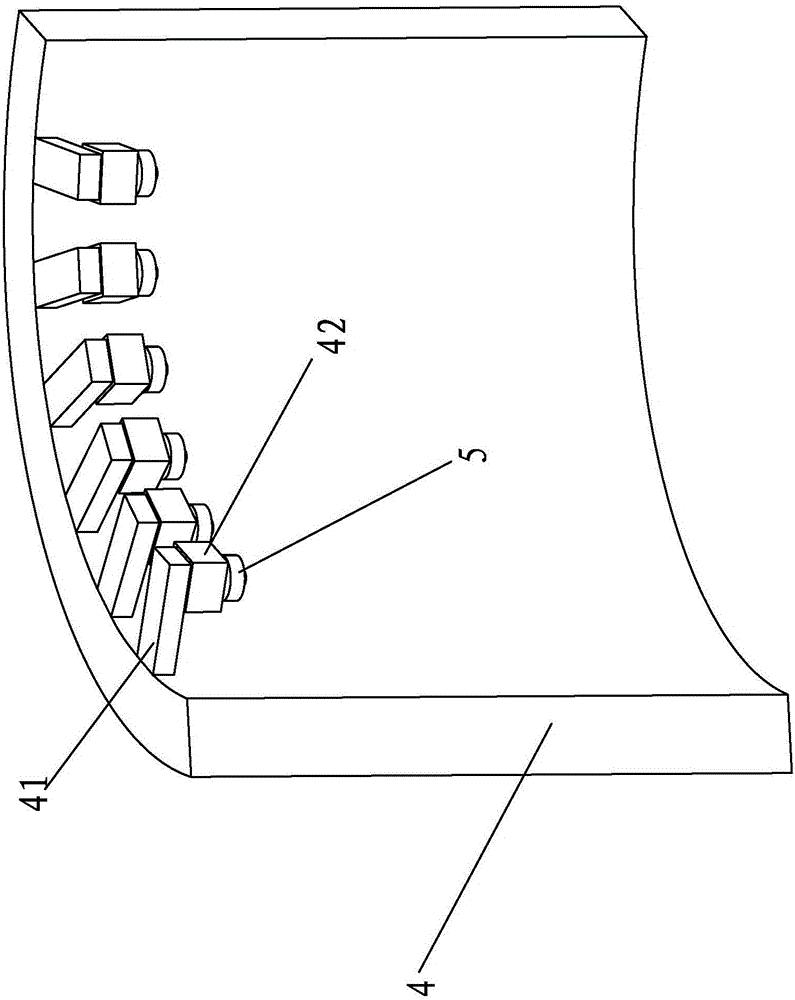

[0034] A large rotary disc stone processing equipment of the present invention, such as Figure 1-4 As shown, it includes a chassis base 1, a lower tray 2 for the workpiece to be processed to be rotated and placed on it, an upper top tray 3 that is directly above the lower tray 2 and can move up and down, and a mounting bracket 4 outside the lower tray 2; Wherein, the lower tray 2 is rotatably installed on the chassis seat 1, and the lower tray 2 is synchronously rotated and connected with the upper top tray 3. One side of the mounting bracket 4 faces the lower tray 2, and the side of the mounting bracket 4 facing the lower tray 2 is the inner side. One side of the lower pallet 2 is the outer side, and the inner side of the mounting bracket 4 is provided with several processing heads 5 for processing the workp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com