Auto-induction cushion block for film laminating machine and using method thereof

An automatic induction and laminating machine technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problem of expensive, automatic backing boards relying on infrared automatic detection means, increasing detection time and response time, etc. problem, achieve the effect of reducing equipment cost, reducing automatic detection means, and reducing a lot of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

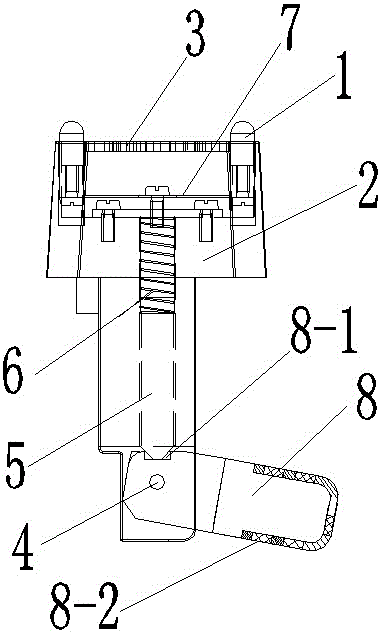

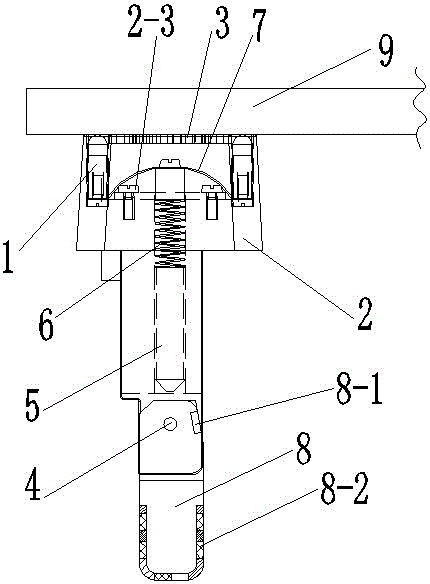

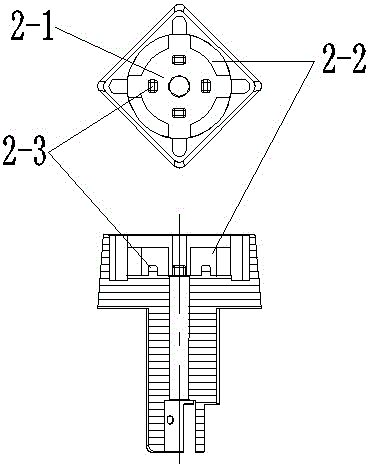

[0026] like figure 1 , figure 2 , image 3 As shown, an automatic induction pad for a laminating machine includes a support rod 2 and a top column 8 hinged to the bottom of the support rod 2 through a pin 4. The upper surface of the support rod 2 is square, and the middle of the support rod 2 is hollow. A positioning column 5 is arranged in the hollow tube, and the lower end of the positioning column 5 is in the shape of a cone. The upper part of the positioning column 5 is covered with a positioning spring 6, and the upper part of the strut 2 is provided with a groove 2-1. The glyph-shaped induction spring piece 7, the center of the induction spring piece 7 is fixedly connected with the top of the positioning column 5, and the four corners of the upper surface of the strut 2 are also provided with four vertical induction push rods 1, and the bottom of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com