A fully automatic quantitative packaging machine for vegetables

A quantitative packaging, fully automatic technology, applied in packaging, wrapping paper, packaged food, etc., can solve the problems that vegetables cannot be automatically and continuously completed, distribution and packaging are time-consuming and labor-intensive, and space utilization is low. Fully functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

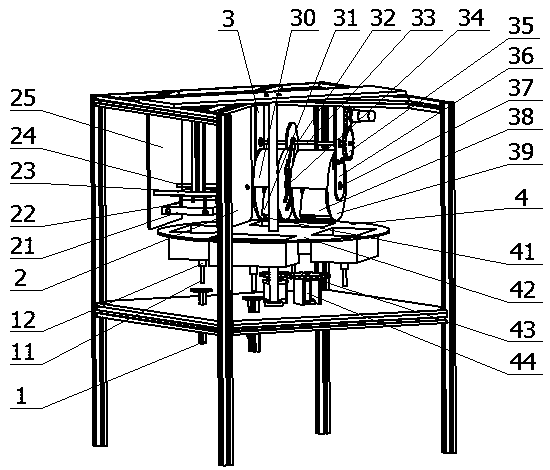

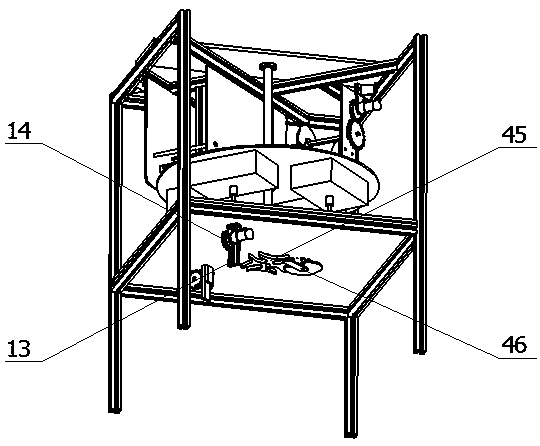

[0010] Such as figure 1 , figure 2 As shown, a fully automatic quantitative packaging machine for vegetables is mainly composed of a transmission mechanism 4 , a vegetable dispensing mechanism 3 , a plastic sealing mechanism 2 and an ejecting mechanism 1 . The transmission mechanism includes a main shaft 41, a turntable 42, a gear shaft 44, a transmission gear 43, a transmission sheave 45 and a transmission arm 46; The sheave 45 is installed on the main shaft 41 lower end; the gear shaft 44 is installed on the lower plate, and the gear shaft 44 upper end cooperates with the transmission gear 43, and the lower end links to each other with the transmission rotating arm 46. Dispensing mechanism 3 comprises large dispensing cylinder 39, small dispensing cylinder 30, large dispensing dish blade 38, small dispensing dispensing blade 31, rotating shaft 33, central shaft 37, positioning plate 36, dispensing sheave 34, rotating arm 32 and side dish gear 35; Big turn dish blade 38, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com