Automatic labeling device on bobbin packaging and conveying equipment and using method thereof

A conveying equipment and automatic technology, applied in packaging, labeling machines, transportation and packaging, etc., can solve the problems of high manual operation error rate, large manpower consumption, waste of resources, etc., to improve work efficiency, reduce defective product rate, The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

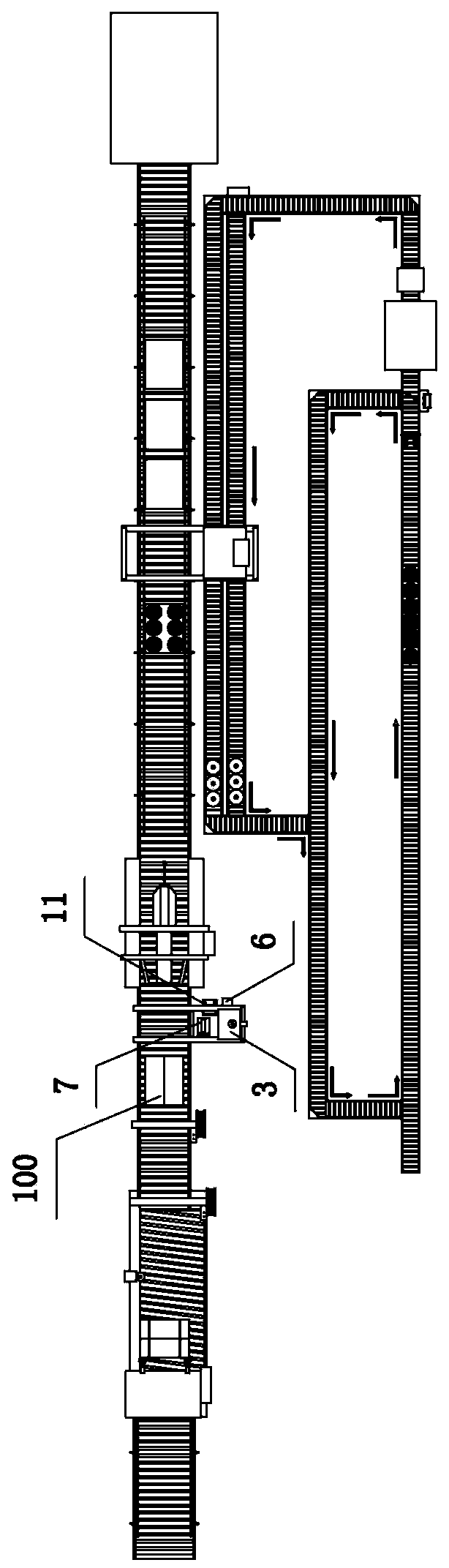

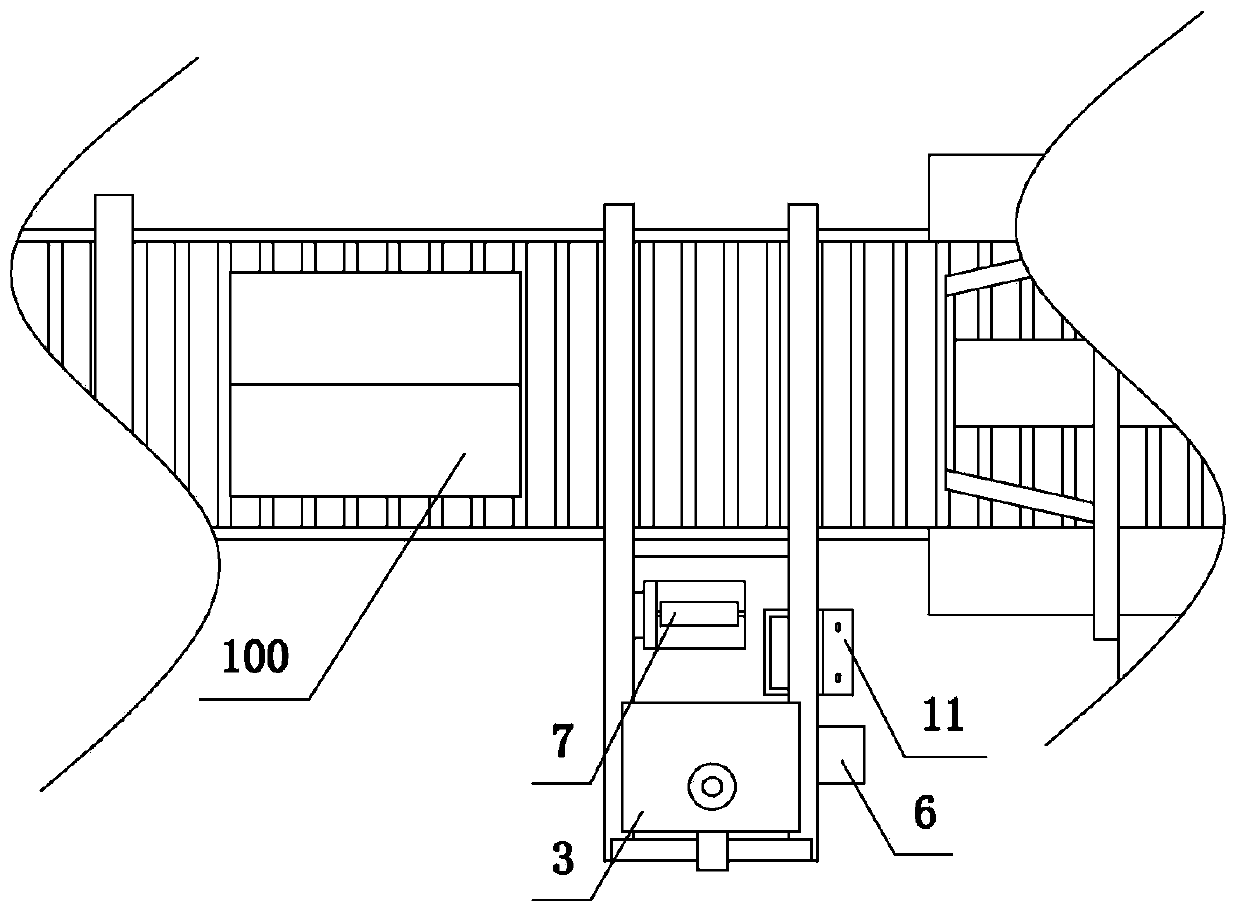

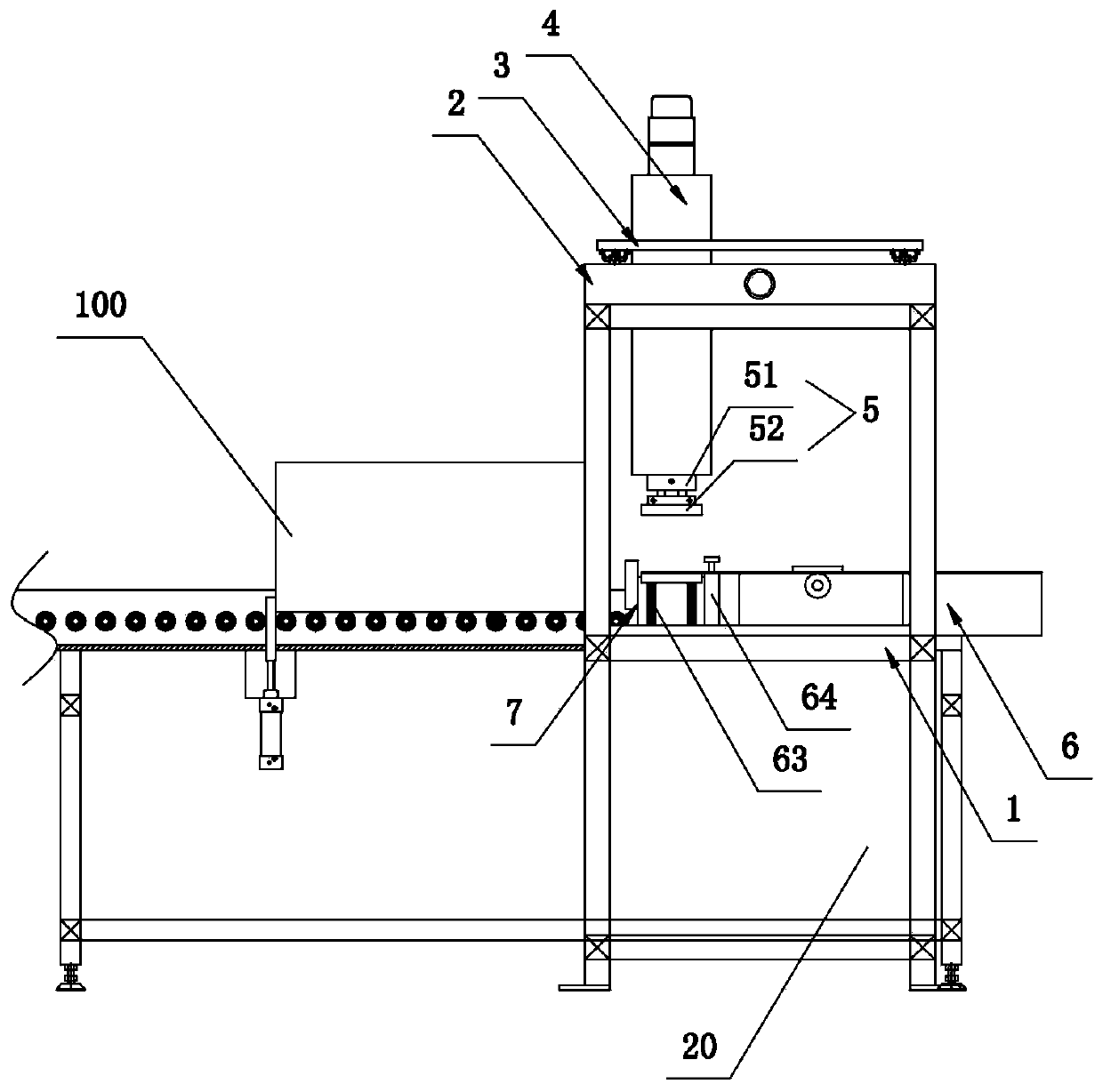

[0043] refer to figure 1 , figure 2 , image 3 and Figure 4 . An automatic labeling device on bobbin packaging and conveying equipment, comprising a labeling device fixing frame 1, a sliding frame 2, a lateral moving mechanism 3, a vertical moving mechanism 4, a vacuum suction mechanism 5, a label conveying mechanism 6, and a label rolling glue Institution7. Wherein, the sliding frame 2 is fixedly installed above the fixed frame 1 of the labeling device; the lateral moving mechanism 3 is slidably installed on the sliding frame 2; The suction mechanism 5 can suck the label 10 located on the labeling device fixed frame 1 and attach the label to the carton 100 to be labeled; the label delivery mechanism 6 can print the label 10 and transport the label to the bottom of the vacuum suction mechanism; the label roll The glue mechanism 7 can automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com