A spiral winding device for making exhaust filter

An exhaust filter and spiral winding technology, applied in the field of spiral winding device, can solve the problems of inaccurate diameter of core tube filter element, inability to meet the requirements of the end face, and increase the tension force, so as to solve the problem of compactness and improve mass production efficiency. , the effect of accurate diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

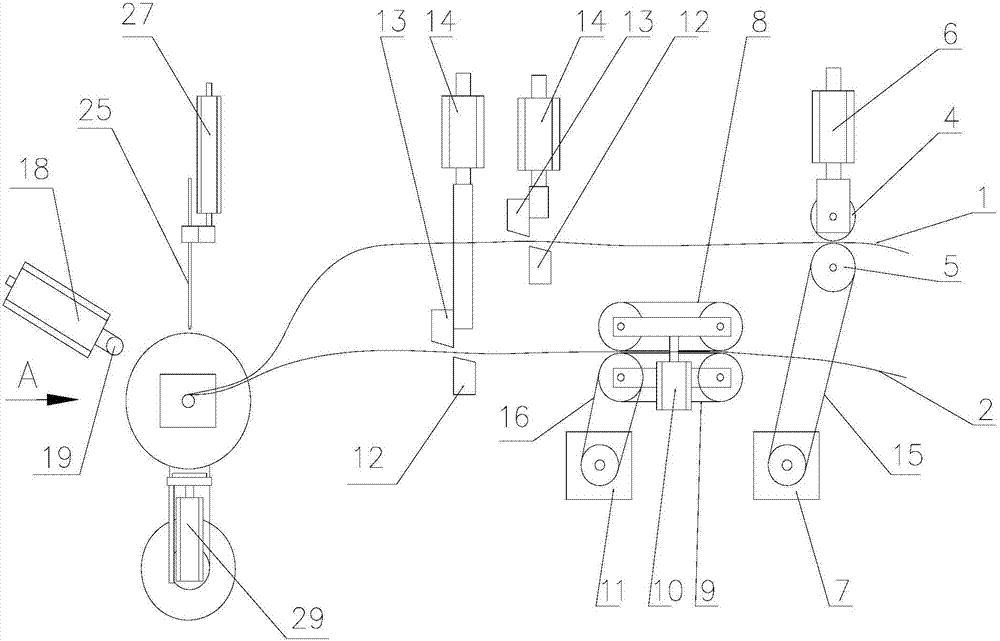

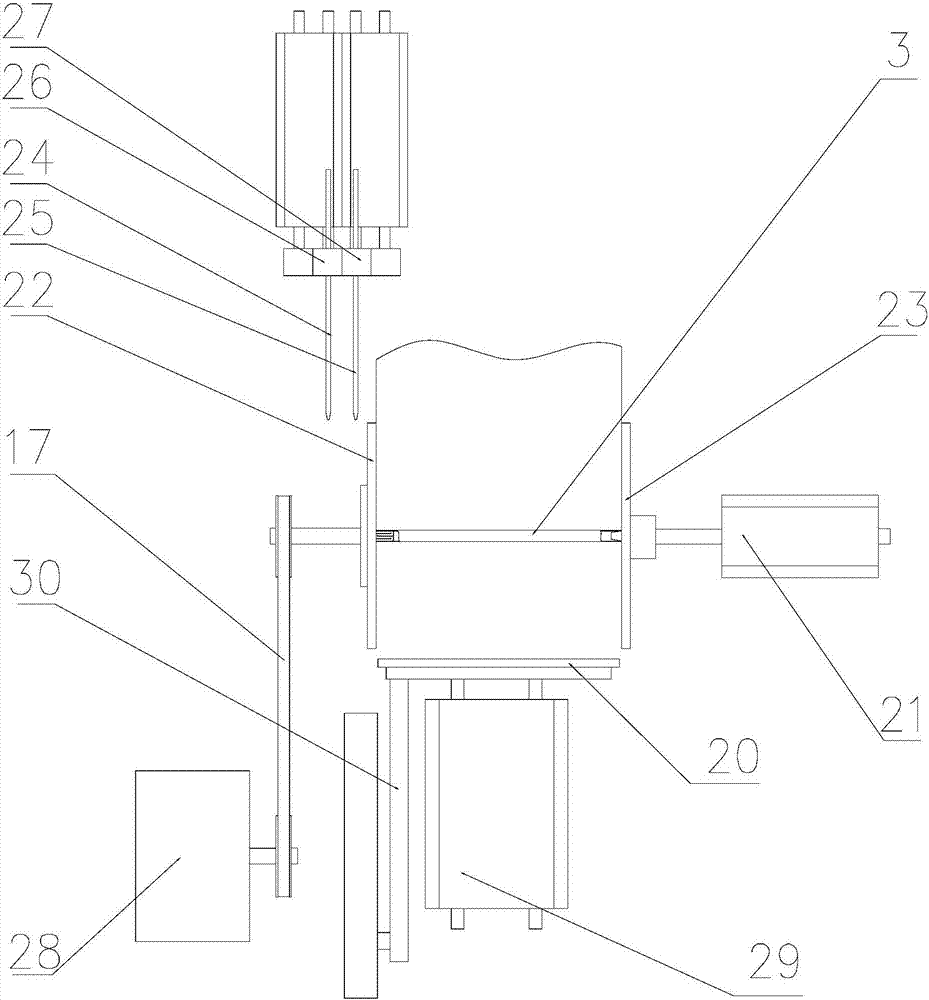

[0024] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0025] The up, down, front and back directions mentioned below are the same as figure 1 The up, down, right, and left directions are the same, and the said left and right directions are the same as figure 2 The left and right directions are the same.

[0026] combine figure 1 and figure 2 Shown is a spiral wound device for making an exhaust gas filter, the exhaust gas filter includes a filter element, and the filter element includes a core tube, a flat plate and a corrugated felt. The winding device includes a first conveying mechanism for conveying the flat plate, a first shearing mechanism for cutting the flat plate, a second conveying mechanism for conveying the corrugated felt, and a second shear for cutting the corrugated felt. Cutting mechanism, welding mechanism for welding the beginning of the flat plate and corrugated felt to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com