A kind of filling material for phosphate mine with high pumpability and preparation method thereof

A technology for filling materials and phosphate mines, applied in the field of filling materials and its preparation, can solve the problems of low bleeding, poor fluidity, and high bleeding, and achieve the effects of reducing bleeding, reducing costs, and reducing bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

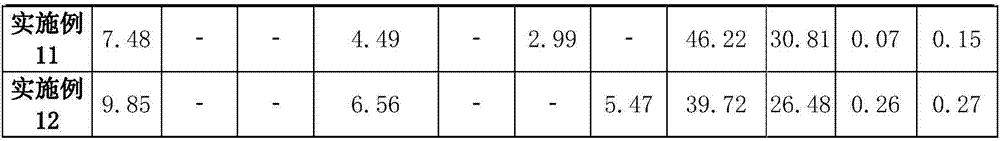

[0025] See Table 1 for the batching of the embodiment of the filling material according to the present invention, and the water-binder ratio remains unchanged at 0.52.

[0026] The preparation method of the above-mentioned filling material for phosphate mines with high pumpability includes the steps of: pouring the cementitious material, aggregates and additives into the mixing tank, starting the mixer, mixing for 5 seconds, adding water slowly, and finishing adding in 20-30 seconds. Start the mixer and stop stirring for 180±5s to prepare the filling material (mixture) for phosphate mines with high pumpability, which is transported to the goaf through pipelines by pumping equipment for filling.

[0027] In accordance with GB / T17671-1999...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com