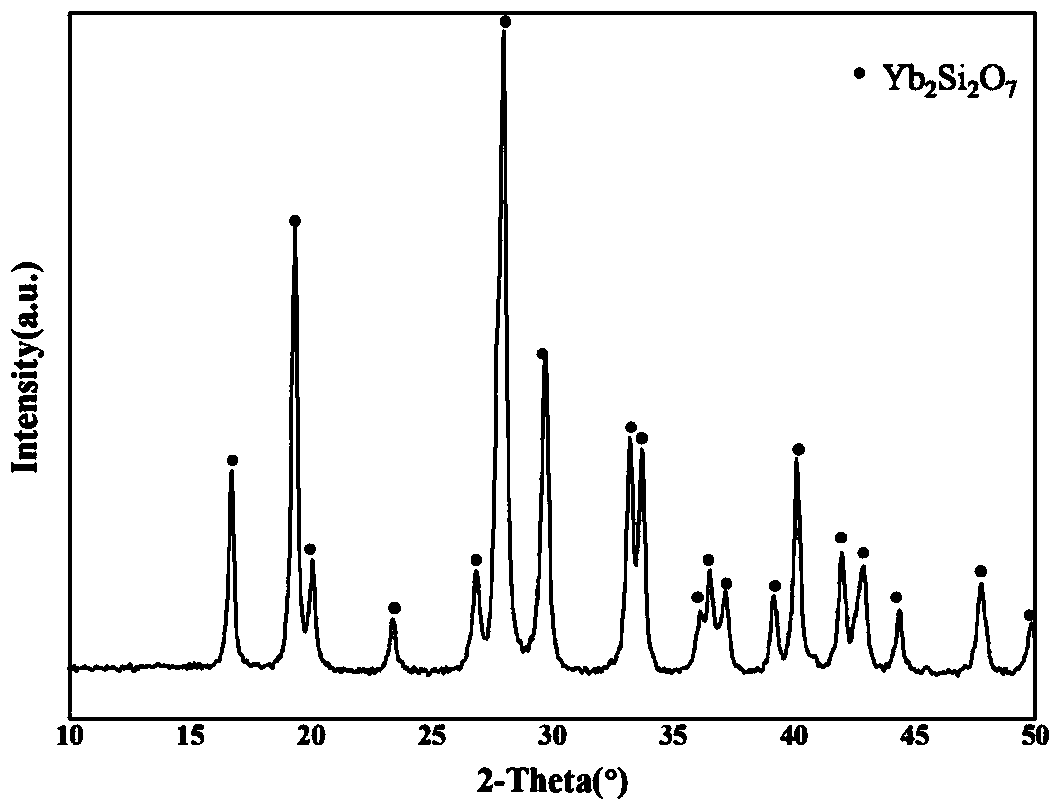

A kind of preparation method of yb2si2o7 powder

A powder, 3·5H2O technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex preparation process, harsh reaction conditions, long reaction cycle, etc., and achieve simple process and high temperature low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a Yb 2 Si 2 o 7 The preparation method of powder comprises the following steps:

[0030] 1) Choose commercially available ytterbium nitrate pentahydrate (Yb(NO) 3 ·5H 2 O), purity ≥ 99.9%; commercially available ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), purity ≥ 99.8%; commercially available sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O), purity ≥ 99.8%; commercially available dehydrated alcohol, purity ≥ 99.8%.

[0031] 2) Weigh Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.1mol / L, and the obtained solution was designated as solution A.

[0032] 3) measure ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O: TEOS = 1: 1, the measured amount of tetraethyl orthosilicate was added to the solution A, put into the magnetic rotor and placed on the magnetic stirrer, and the solution B was obtained after stirring for 1 hour.

[0033] 4) Pour solution B into a hydrot...

Embodiment 2

[0038] a Yb 2 Si 2 o 7 The preparation method of powder comprises the following steps:

[0039] 1) Choose commercially available ytterbium nitrate pentahydrate (Yb(NO) 3 ·5H 2 O), purity ≥ 99.9%; commercially available ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), purity ≥ 99.8%; commercially available sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O), purity ≥ 99.8%; commercially available dehydrated alcohol, purity ≥ 99.8%.

[0040] 2) Weigh Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.15mol / L, and the obtained solution was designated as solution A.

[0041] 3) measure ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O:TEOS=1:1.5, add the measured tetraethyl orthosilicate into the solution A, put it into the magnetic rotor and place it on the magnetic stirrer, and get the solution B after stirring for 1.5h.

[0042] 4) Pour solution B into a hydrothermal kettle, tighte...

Embodiment 3

[0047] a Yb 2 Si 2 o 7 The preparation method of powder comprises the following steps:

[0048] 1) Choose commercially available ytterbium nitrate pentahydrate (Yb(NO) 3 ·5H 2 O), purity ≥ 99.9%; commercially available ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), purity ≥ 99.8%; commercially available sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O), purity ≥ 99.8%; commercially available dehydrated alcohol, purity ≥ 99.8%.

[0049] 2) Weigh Yb(NO) 3 ·5H 2 O, fully dissolved in absolute ethanol, prepared into a solution with a concentration of 0.2mol / L, and the obtained solution was designated as solution A.

[0050] 3) measure ethyl orthosilicate (Si(OC 2 h 5 ) 4 ), according to Yb(NO) 3 ·5H 2 The molar ratio of O: TEOS = 1: 2. Add the measured tetraethyl orthosilicate to solution A, put it into a magnetic rotor and place it on a magnetic stirrer, and stir for 2 hours to obtain solution B.

[0051] 4) Pour solution B into a hydrothermal kettle, tighten the hydrothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com