Single-thread elastic yarn feeder

A yarn feeder and elastic band technology, applied in textile and paper making, weft knitting, knitting and other directions, can solve problems such as thickness reduction and achieve the effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

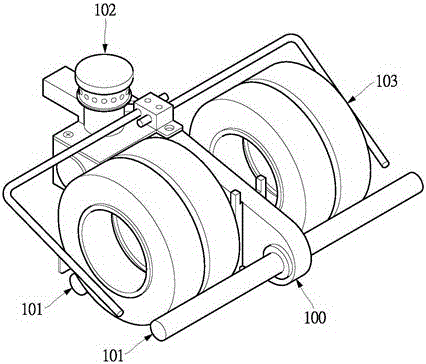

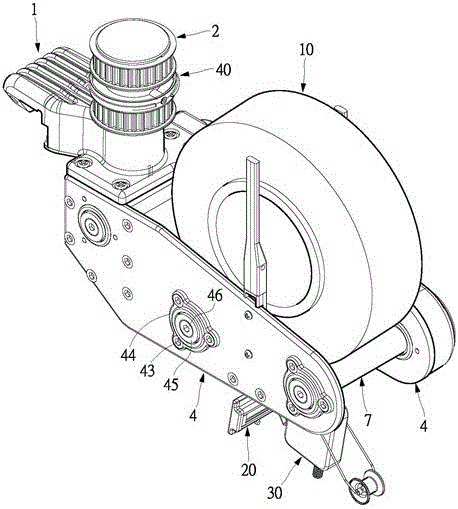

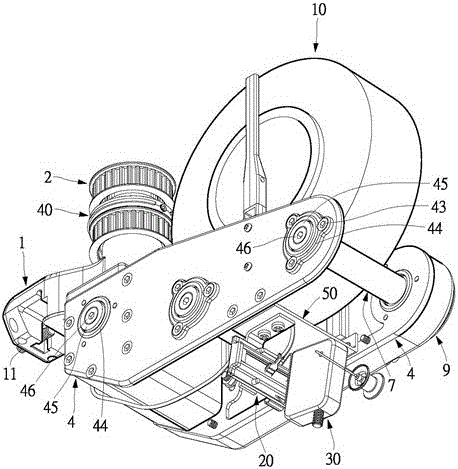

[0065] Please refer to Figure 2 to Figure 7 As shown, the present invention provides a single-thread elastic yarn feeder, which includes a support frame 1, at least one driving wheel 2, a transmission shaft 3, two bearing plates 4, a mandrel 5, a gear set 6, and two support rods 7 and a pulley set 8.

[0066]The driving wheels 2 can be provided with one, two, or three, four and so on. In this embodiment, two driving wheels 2 are provided, and a clutch 40 is provided between the two driving wheels 2 . The drive wheel 2 is connected to the upper end of the transmission shaft 3, and the transmission shaft 3 is pivotally arranged on the support frame 1, so that the drive wheel 2 and the transmission shaft 3 can freely rotate on the support frame 1, and the drive wheel 2 Can be driven with strap components such as belts. A fixing screw 11 can be provided on the support frame 1, so that the whole yarn feeder is fixed on the hoop of the knitting machine.

[0067] The two bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com