A kind of composite accompanying environmental protection imitation goose down thermal insulation material and its production method

A goose down and environmental protection technology, applied in the field of traditional wear and non-woven materials, can solve the problems of easy allergy, easy to harden, easy to mildew, etc., and achieve the effect of expanding the scope of use, not easy to drill down, and promoting development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

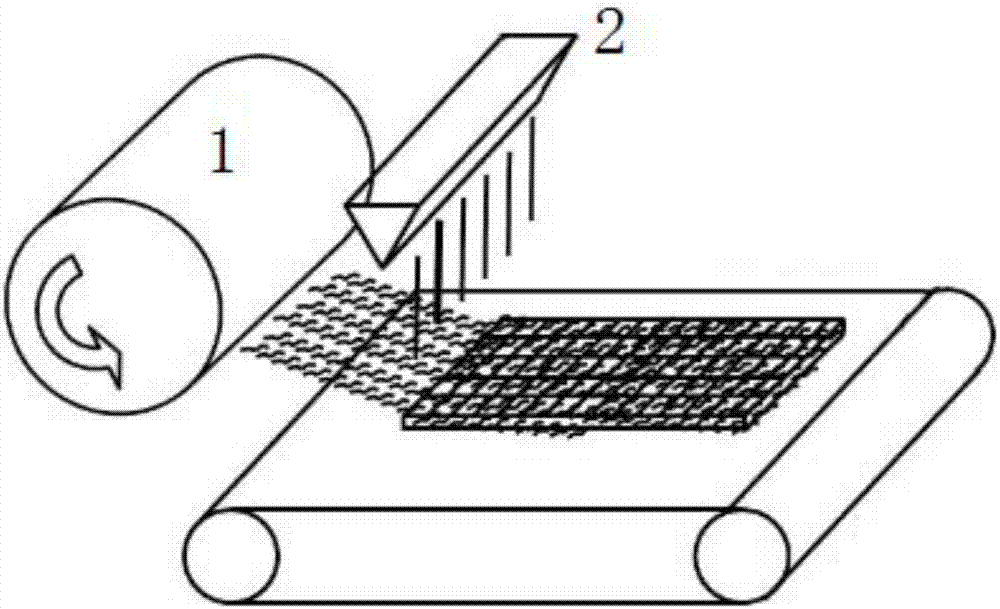

[0028] PLA resin slices enter the screw extruder for melt spinning, and go through the gradually heated extruder zone 1, extruder zone 2, extruder zone 3, extruder zone 4, extruder zone 5 and extrusion Melting in the six zones of the extruder (the temperature of the six zones of the extruder and the temperature of the extruder outlet are respectively set to 160°C, 165°C, 170°C, 175°C, 180°C, 185°C, 190°C), and then filtered The components intercept and filter the impurities in the slices, and finally the completely molten melt is sprayed out from the spinneret, and falls on the mesh delivery curtain of the melt-blown equipment 2 under the drafting of the high-speed hot air flow to form PLA melt-blown ultra-fine short fibers. Among them, the drawing temperature of the melt-blown hot air flow is 200°C, and the spinning speed is 600m / min; the cashmere is loosened on the conveyor net curtain added near the spinneret and sent to the roller 1 to be combed into a single fiber state, a...

Embodiment 2

[0031] PLA resin slices enter the screw extruder for melt spinning, and go through the gradually heated extruder zone 1, extruder zone 2, extruder zone 3, extruder zone 4, extruder zone 5 and extrusion Melt in the six zones of the extruder (the temperature of the six zones of the extruder and the temperature of the extruder outlet are set to 163°C, 168°C, 173°C, 178°C, 183°C, 188°C, 200°C respectively), and then filtered The components intercept and filter the impurities in the slices, and finally the completely molten melt is sprayed out from the spinneret, and falls on the mesh delivery curtain of the melt-blown equipment 2 under the drafting of the high-speed hot air flow to form PLA melt-blown ultra-fine short fibers. Among them, the drawing temperature of the melt-blown hot air flow is 230°C, and the spinning speed is 800m / min; the alpaca is loosened on the conveyor net curtain added near the spinneret and sent to the roller 1 to be combed into a single fiber state, and th...

Embodiment 3

[0034] PLA resin slices enter the screw extruder for melt spinning, and go through the gradually heated extruder zone 1, extruder zone 2, extruder zone 3, extruder zone 4, extruder zone 5 and extrusion Melt in the six zones of the extruder (the temperature of the six zones of the extruder and the temperature of the extruder outlet are set to 163°C, 168°C, 173°C, 178°C, 183°C, 188°C, 200°C respectively), and then filtered The components intercept and filter the impurities in the slices, and finally the completely molten melt is sprayed out from the spinneret, and falls on the mesh delivery curtain of the melt-blown equipment 2 under the drafting of the high-speed hot air flow to form PLA melt-blown ultra-fine short fibers. Among them, the drawing temperature of the melt-blown hot air flow is 230°C, and the spinning speed is 800m / min; the alpaca is loosened on the conveyor net curtain added near the spinneret and sent to the roller 1 to be combed into a single fiber state, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com