Special turnout for endless rope continuous traction system

A traction system and endless rope technology, which is applied in the field of special turnouts for continuous traction systems with endless ropes, can solve problems such as bending and breaking of curved rails in turnouts, affecting transportation efficiency, and rail deformation, so as to achieve stable vehicle rejection, improve transportation efficiency, Reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

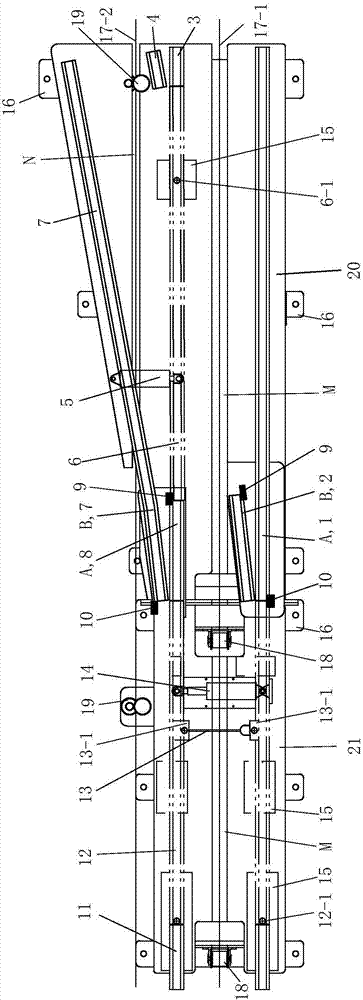

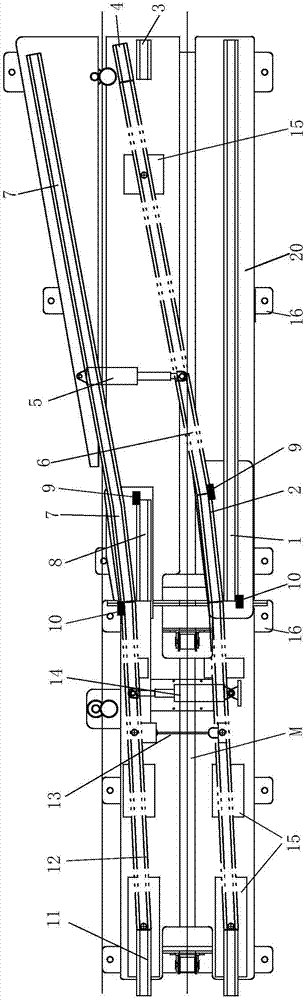

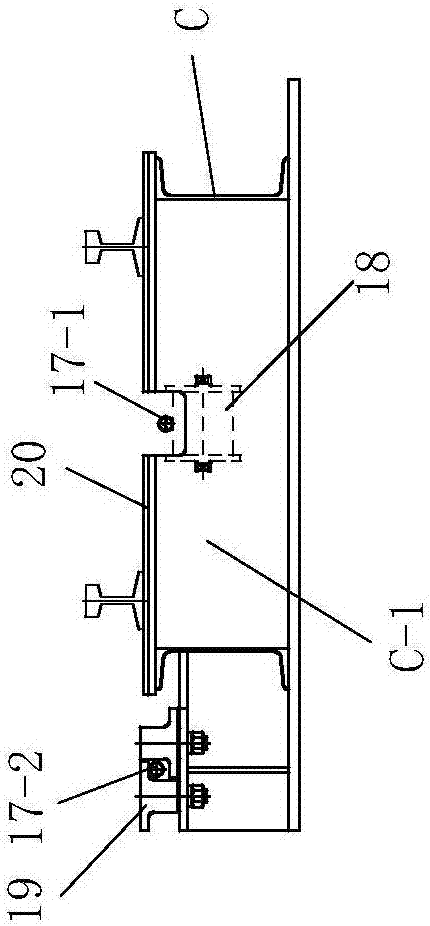

[0014] See Figure 1 to Figure 3 Shown is a special turnout for the endless rope continuous traction system with single rope traction. The special turnout has a front main frame and a rear main frame. The front and rear main frames are respectively composed of a frame C and a panel fixed on the frame C. The front and rear The main frame must have sufficient load-bearing strength. The front and rear main frames are positioned through the pin shaft guide and fastened with bolts, which is convenient for quick positioning and installation.

[0015] The left and right sides of the front body frame and the rear body frame are respectively fixed with connecting seats 16, and the front and rear body frames are respectively fixed on the bottom of the pit by anchor rods through the connecting seats 16. The track surfaces of the front and rear main frames are at least 0.1 meters higher than the conventionally laid track surfaces, and the track of a section close to the special turnout on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com