A method for lateral tensioning of a cable system with a space cable-plane structure

A horizontal and spatial technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problem of lack of a mature and reliable construction method, and achieve the effect of reducing the difficulty of construction management, ensuring project quality, and simple tooling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

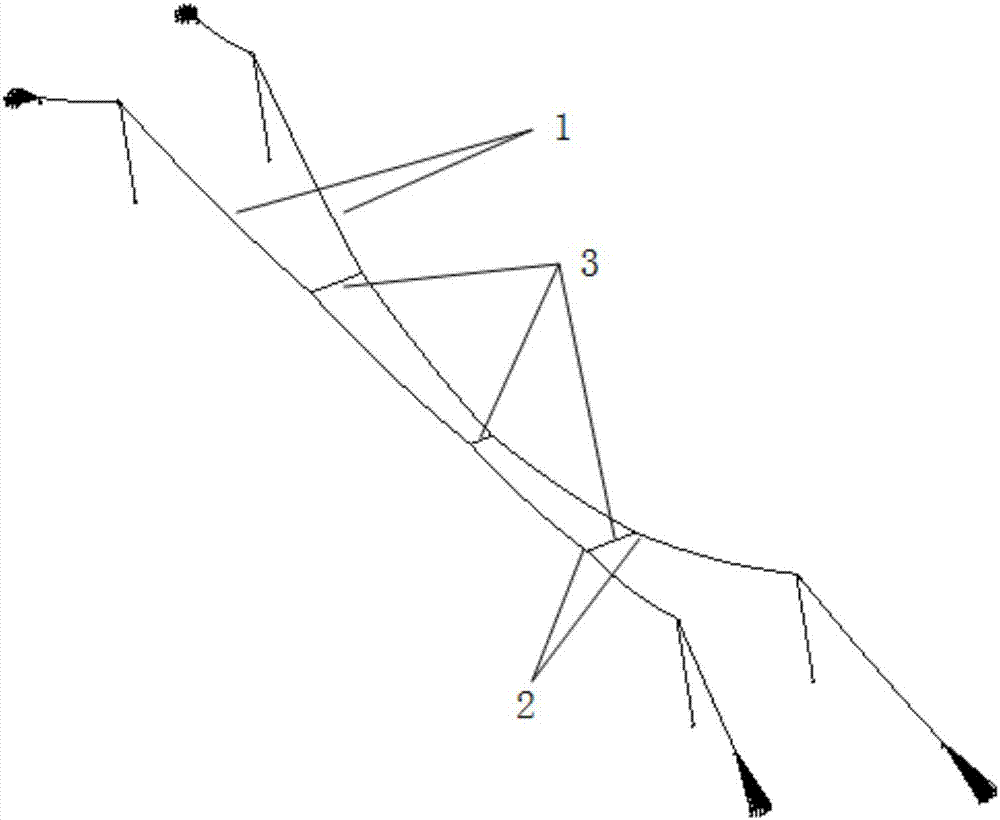

[0025] (1) After the main cable tightening of the space cable surface structure suspension bridge is completed, the main cable clamps are installed on the two main cables respectively;

[0026] (2) According to the BNLAS computer structure calculation software, the number of horizontal pairings required for the transformation of the main cable space system is 3, and one transverse pairing is arranged at 1 / 4, 1 / 2, and 3 / 4 of the main span of the suspension bridge. device.

[0027] (3) Hang the catwalk on the two main cables so that the catwalk moves laterally with the two main cables;

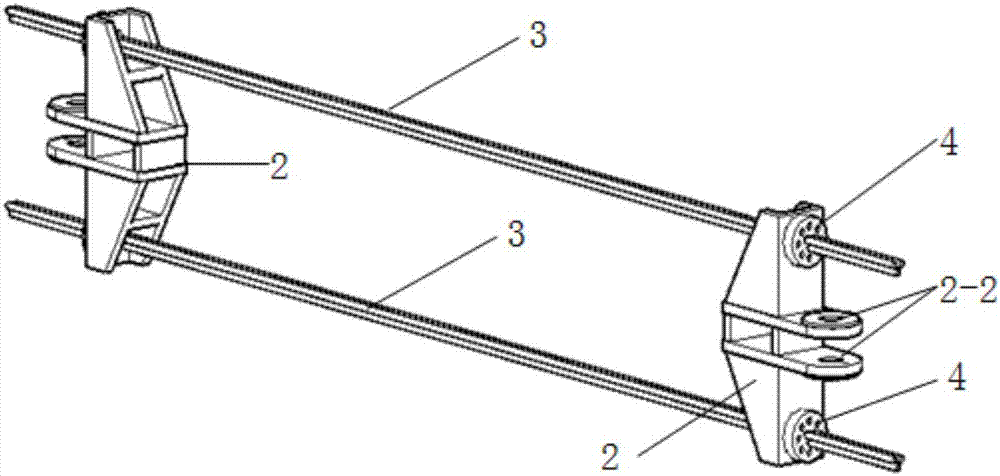

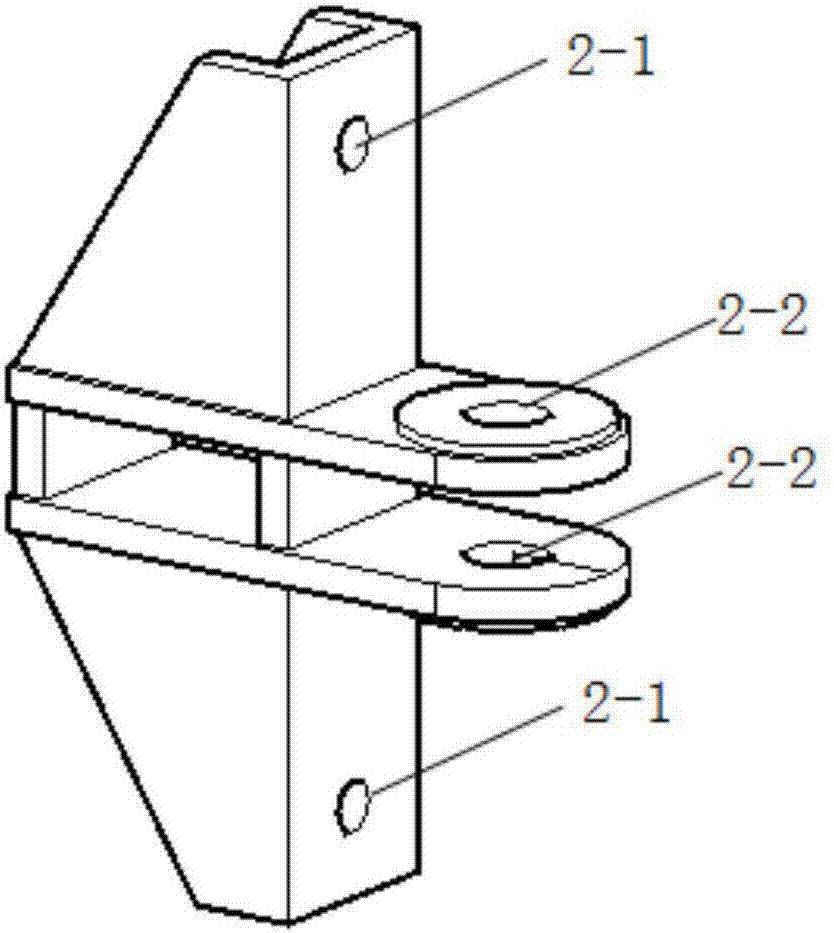

[0028] (4) According to the position of the horizontal pull set in step (2), install the horizontal pull device on the catwalk. -2 Connect multiple pairs of main cable pull bases 2 with the main cable clips on the two main cables 1 respectively; Two main cable pull seats 2, each main cable pull seat 2 respectively includes a seat body, symmetrically opened in the middle of the upper part and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com