Hoisting method for large-span steel structure of limited working face in heating furnace area

A hoisting method and heating furnace technology, which are applied in building structure, building material processing, construction and other directions, can solve the problems that cranes cannot be hoisted, the construction site cannot be hoisted in place at one time, and the hoisting environment in the heating furnace area is complex, etc. The effect of hoisting construction progress, improving construction efficiency and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated below by specific examples.

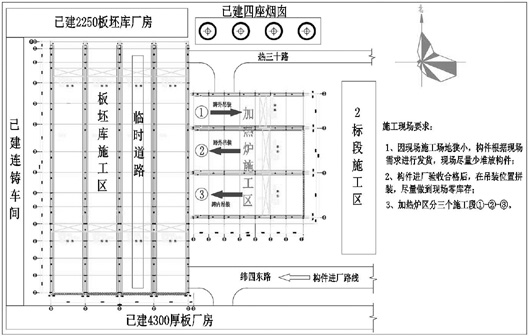

[0030] Such as Figure 1~Figure 8 As shown, a hoisting method for a large-span steel structure with a restricted working surface in the heating furnace area, including

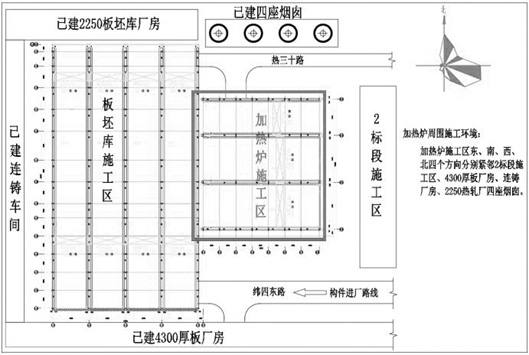

[0031] Step (1) Understand the construction environment: understand the construction status in the east, south, west and north directions of the heating furnace area, the distribution of existing buildings, roads and aerial work surfaces;

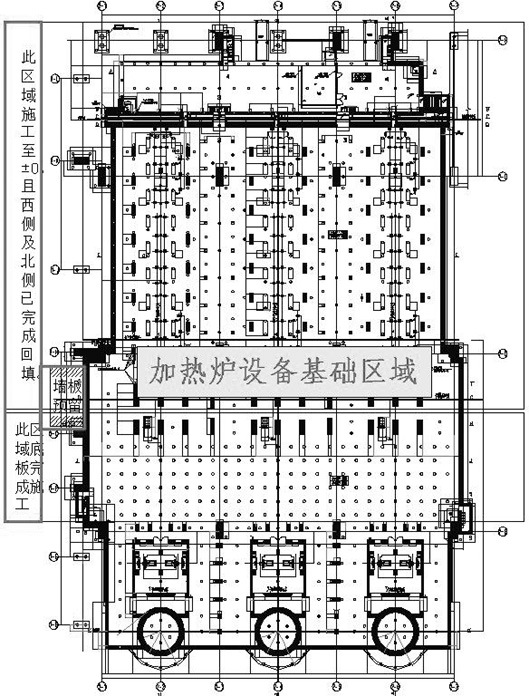

[0032] Step (2) The construction conditions are reserved in advance for the hoisting of the steel structure during the preliminary construction: when the roof beams of the heating furnace are hoisted, the equipment foundation of the heating furnace has been constructed to ±0, and the strength of the bottom plate and column foundation has reached the design strength, ensuring that the heating The earthwork backfilling on the northwestern sides adjacent to the furnace has been completed, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com