Spray dust-removal haze-removal vehicle with vector nozzle

A vector and nozzle technology, applied in the field of environmental protection, dust removal and haze prevention in construction sites and mines, can solve the problems of short spray range, inflexible operation, environmental pollution, etc., and achieve the effect of reducing labor intensity, high speed, good dust suppression and dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

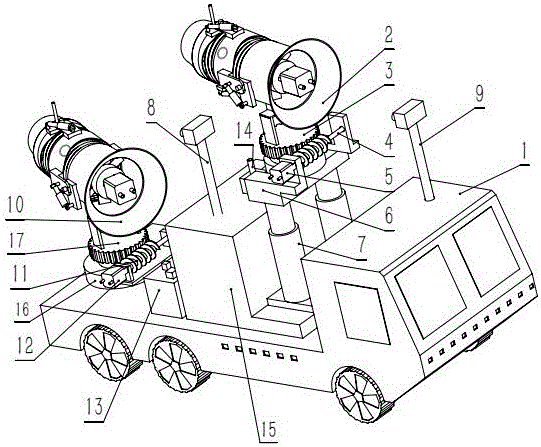

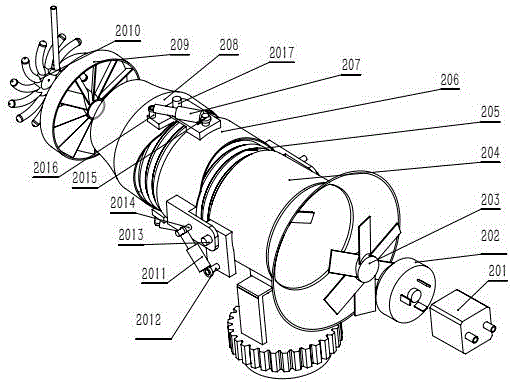

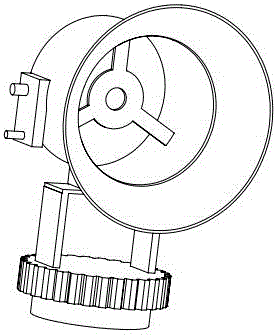

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a spray dust removal and haze removal vehicle with a vector nozzle includes a six-wheeled automobile chassis 1, a front vector cyclone sprayer 2, a first worm wheel 3, a first worm 4, a first plunger hydraulic motor 5, and a lifting platform 6. Double hydraulic cylinder 7, rear camera 8, front camera 9, rear vector cyclone sprayer 10, second worm 11, second plunger hydraulic motor 12, hydraulic system 13, high-pressure water pump 14, water tank 15, rotating base 16 , the second worm wheel 17, the display in the car, the central controller, it is characterized in that: the described front vector cyclone sprayer 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com