Intake mechanism of rotary engine

A technology of air intake mechanism and engine, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., and can solve the problems of insufficient fuel economy and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

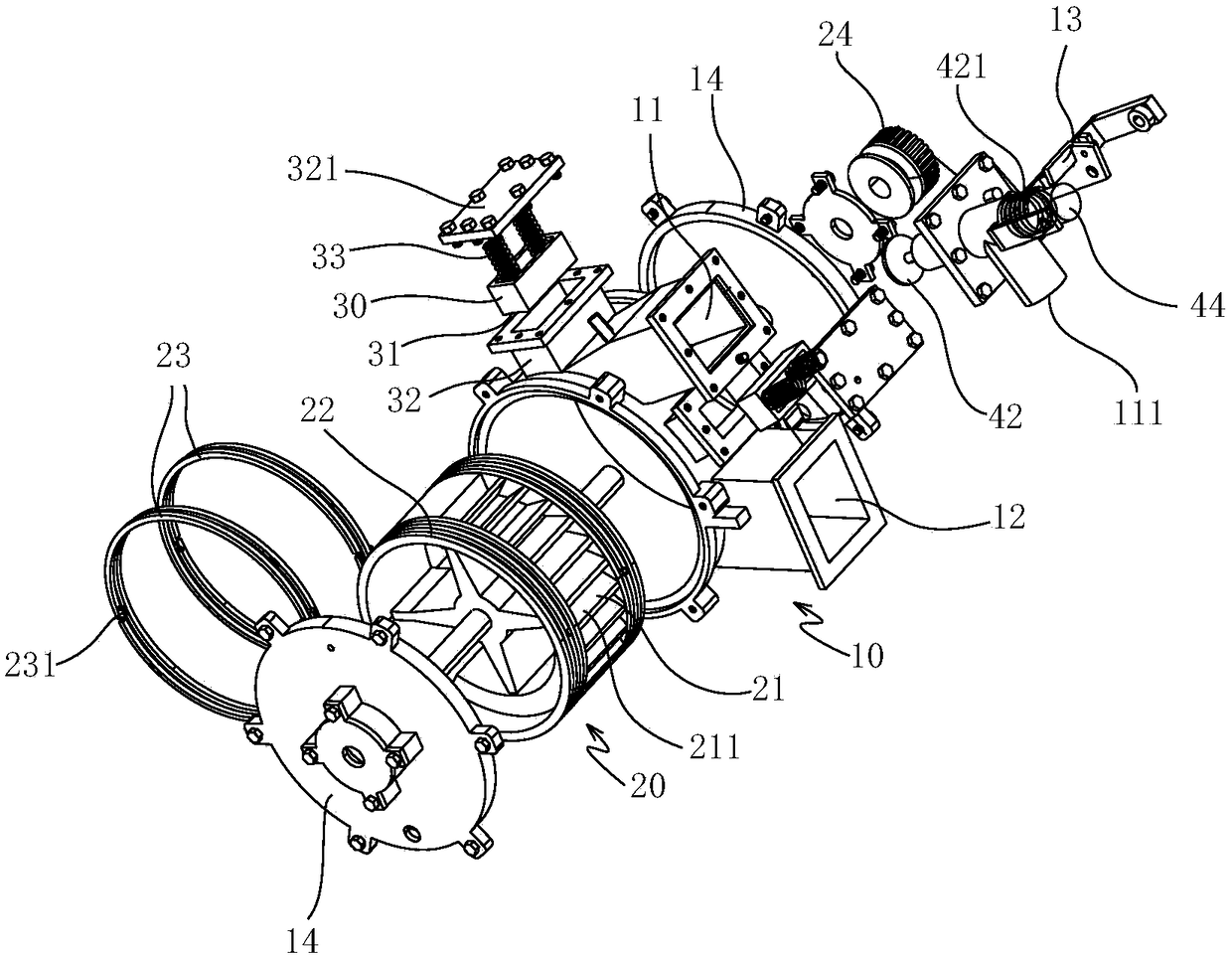

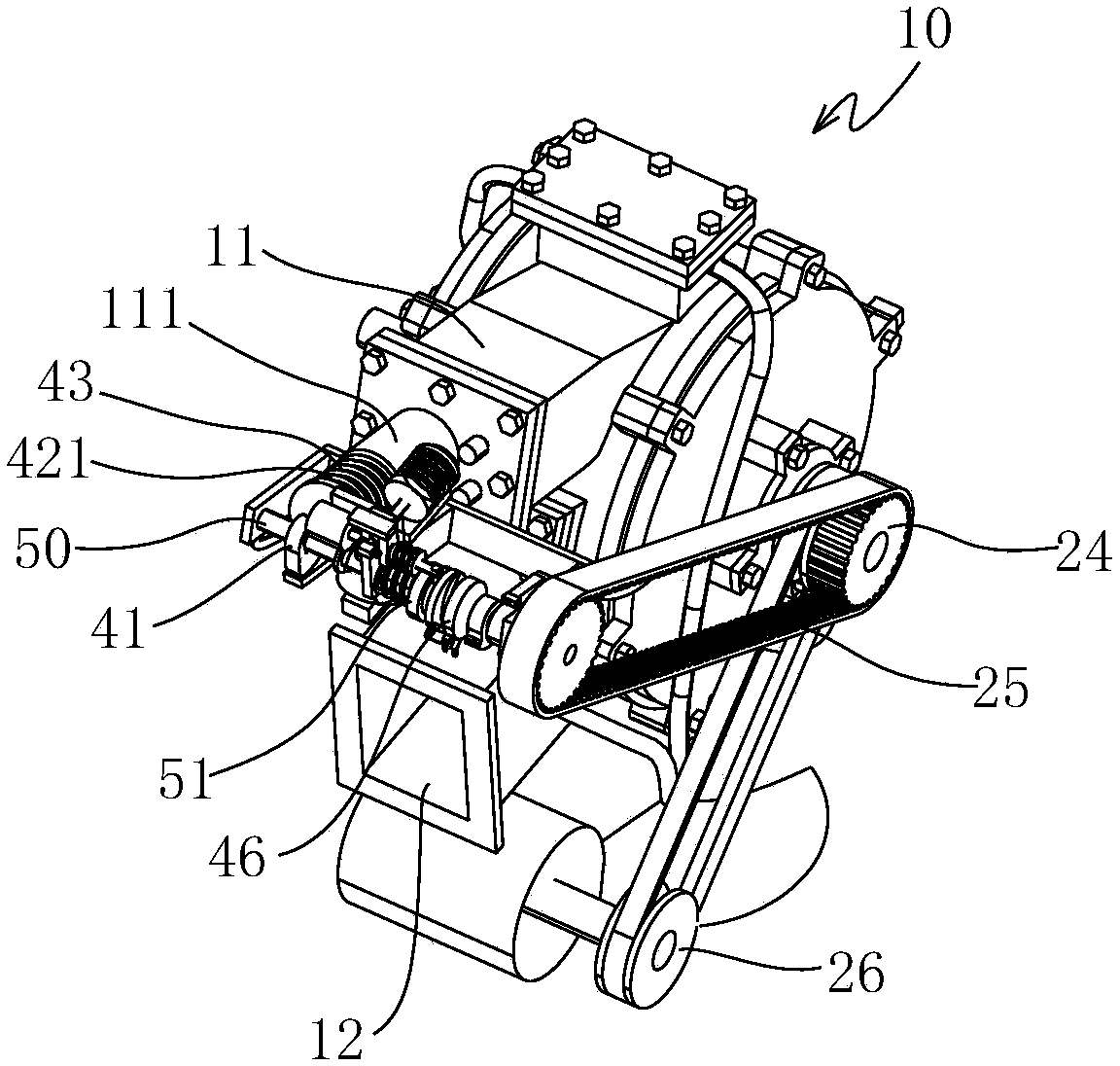

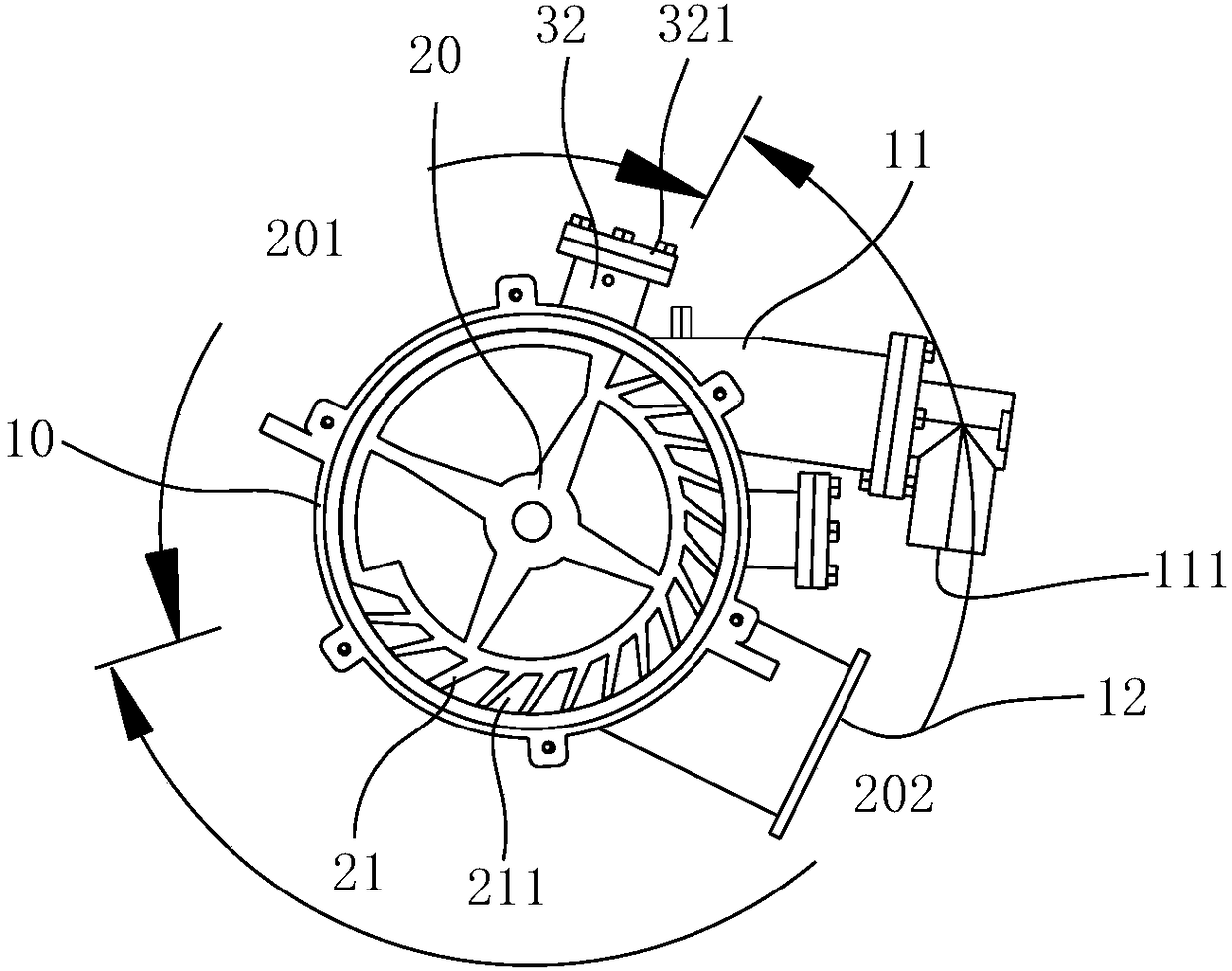

[0027] refer to Figure 1 to Figure 10 , the structural features of the present invention are described in detail as follows:

[0028] At first other structures of the rotary engine of the present invention are briefly introduced:

[0029] combine figure 1 with image 3 with Figure 4 , the rotary engine includes an engine block 10, a rotary wheel 20 is arranged in the cylinder block 10, a combustion chamber 11 and an exhaust pipe 12 are arranged on the cylinder block 10, and a fuel injection unit and an ignition unit are arranged in the combustion chamber 11. unit, the combustion chamber 11 is also provided with an air intake pipe 111, the air intake pipe 111 communicates with the combustion chamber 11 and is filled with compressed gas, the runner 20 is cylindrical as a whole, and the outer wall of the runner 20 is provided with multiple blades 21. The blades 21 are strip-shaped and the length direction is arranged along the axial direction of the runner 20. The chamber e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com