Starting method for reversed positioning and pressure reduction of engine

An engine and reverse technology, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of small engine compression resistance, large engine compression resistance, excessive reverse angle, etc., to increase engine speed and reduce startup Resistance, prolonging the working time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

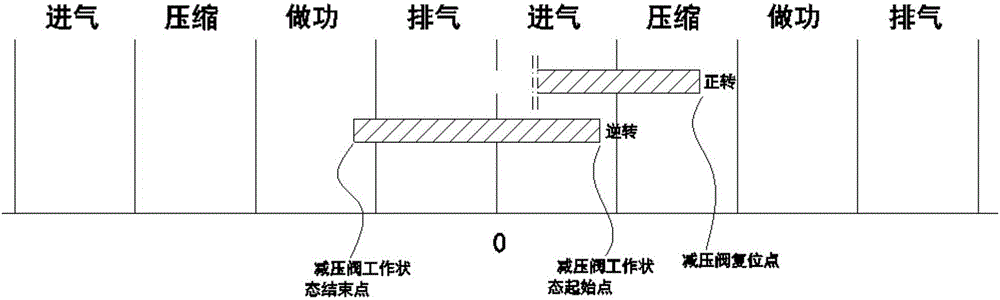

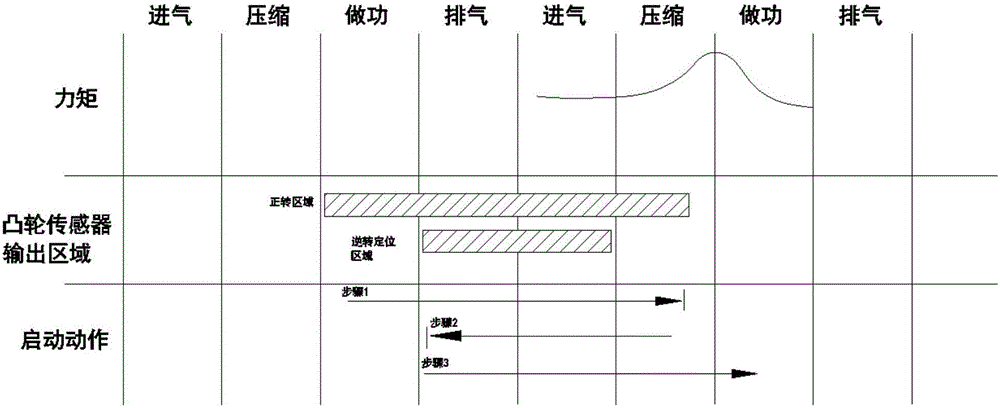

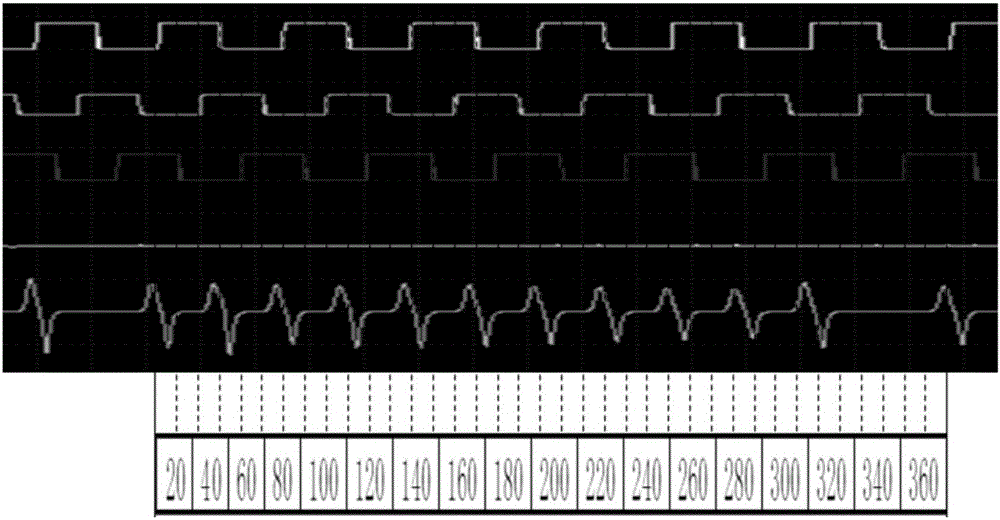

[0034] Such as figure 1 , figure 2 , Figure 5 , Image 6 As shown, a method for reverse start of an engine according to the present invention includes the following steps:

[0035] 1) Before starting, control the motor to rotate forward to make the crankshaft rotate to the compression stroke;

[0036] 2) After the crankshaft rotates forward to the compression stroke, control the starter motor to reverse to make the crank enter the decompression zone;

[0037] 3) After the crank enters the decompression zone, the motor is controlled to rotate forward with a large torque.

[0038] This embodiment is controlled in response to the engine start operation. When the engine is started for the first time, or when another abnormality occurs and the engine is not in a decompressed state, the starting method can be used. The starting method is to reverse th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com