Semi-active Vibration Isolation Actuator Based on Permanent Magnetic Electromagnetic Composite

An electromagnetic composite, semi-active technology, applied in the direction of shock absorber, spring/shock absorber functional characteristics, magnetic spring, etc., can solve the problems of inability to reduce system stiffness, increase system stiffness, and high force transmission rate, and achieve good results. Vibration isolation, system stiffness reduction, and complexity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

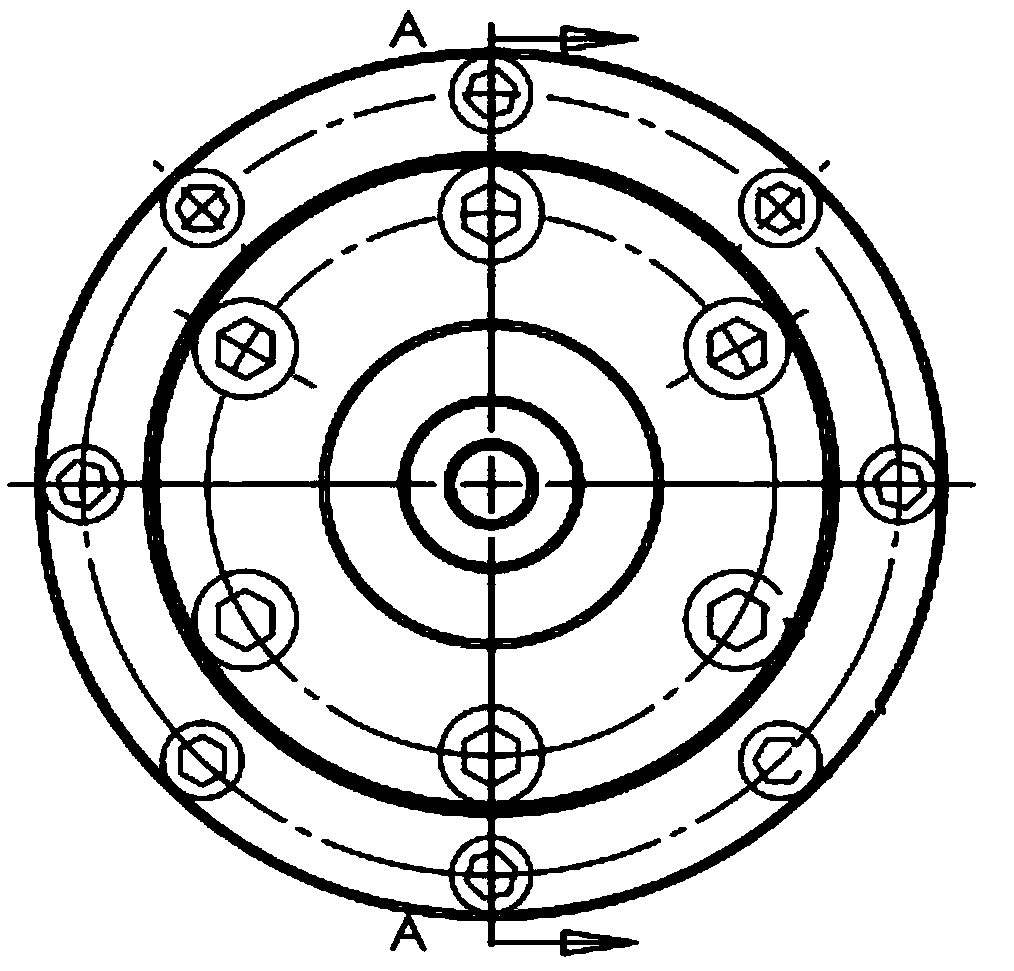

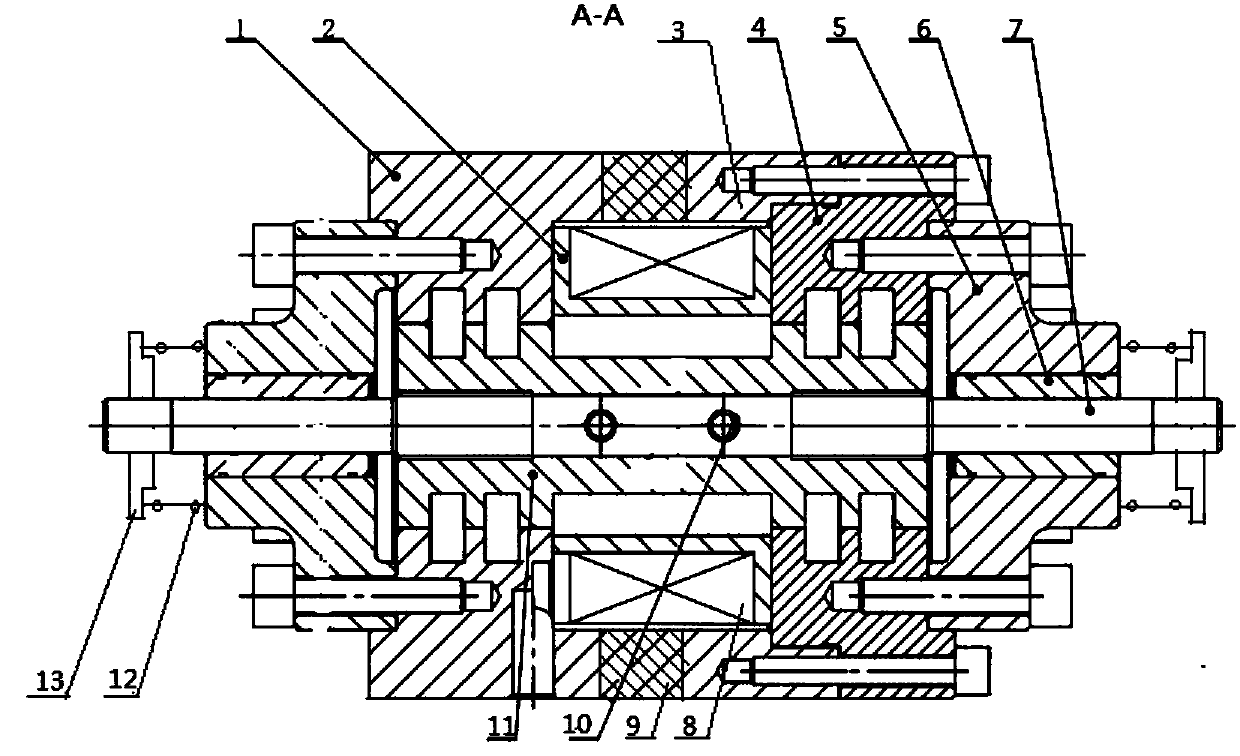

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] combine Figure 1-2 , the present invention mainly includes a first housing 1, a coil frame 2, a second housing 3, a flange 4, a bearing end cover 5, a linear bearing 6, a main shaft 7, a coil winding 8, a permanent magnet 9, an elastic cylindrical pin 10, Armature 11, spring 12, nut 13.

[0021] The first housing 1 , the flange 4 and the armature 11 are provided with small teeth with variable pitch and width, so as to obtain a better linear characteristic of displacement-electromagnetic force. There is a working air gap of a certain size between the teeth on the first housing, the flange and the teeth on the armature.

[0022] The first shell 1, the second shell 3, the flange 4 (that is, the stator) and the armature 11 (that is, the mover) are all made of electrical pure iron with good magnetic conductivity; the permanent magnet 9 is made of high-perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com