Steel-concrete combined beam and construction method thereof

A reinforced concrete and concrete technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of structural performance, construction speed and construction cost can not be well balanced, and achieve weight reduction, fast construction speed, good effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

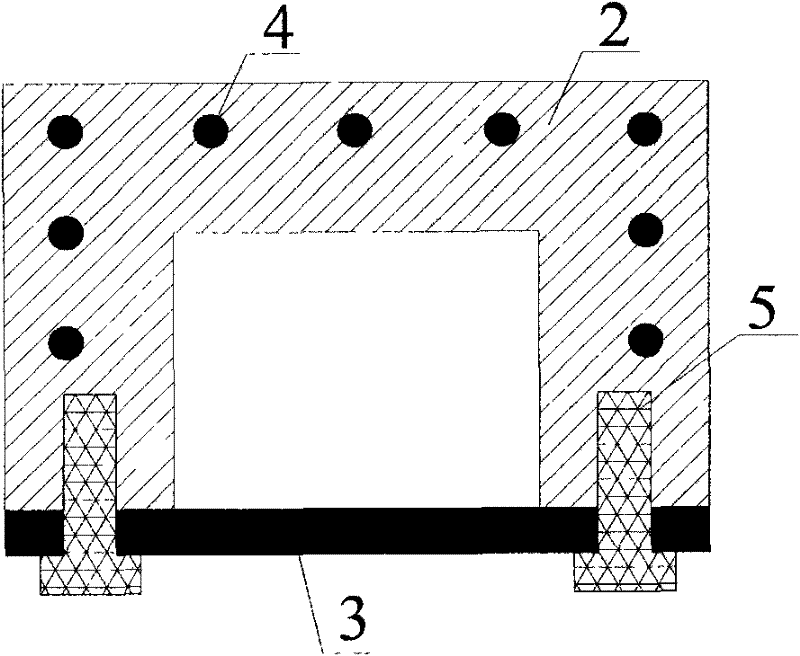

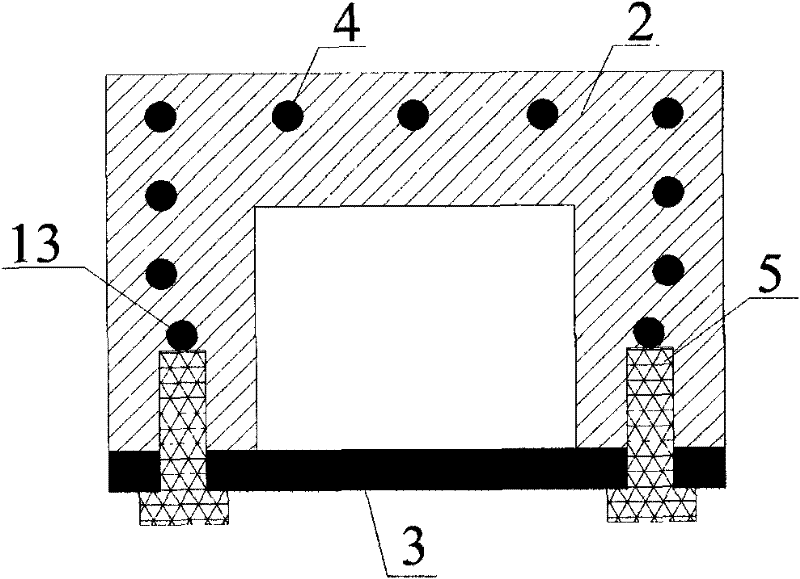

[0034] refer to figure 2 , a steel-concrete composite beam, which mainly includes a reinforced concrete part 2 for compressive resistance and a steel member part 3 for tensile resistance, and the steel member part is made of a steel plate. The reinforced concrete part 2 is an inverted U-shaped section, and the steel plate part and the reinforced concrete part 2 are connected by bolts. The long steel bars 13 connecting the embedded bolts are arranged between the screw rods to connect to each other.

Embodiment 2

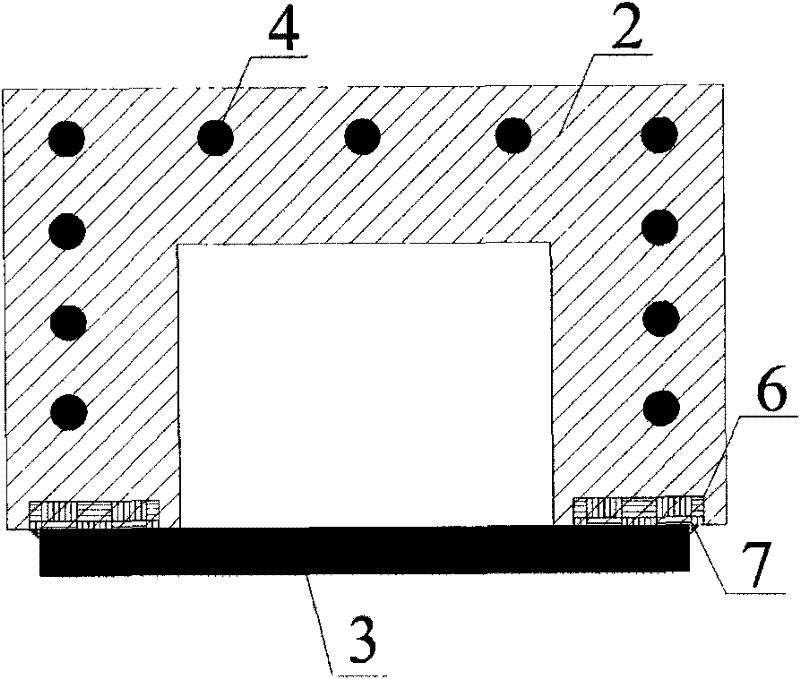

[0036] A construction method for a steel-concrete composite beam: first make an inverted U-shaped mold, put steel bars into the mold and fix it, then pour concrete into the mold to make a U-shaped reinforced concrete member, and set the pre-buried in the concrete Screw rod 5, and finally weld the steel plate to the embedded connector or put the steel plate on the screw rod and tighten it with nuts to form a steel-concrete composite beam. Steel-concrete composite beams connected to walls ( Figure 5 ), the composite beam is placed on the wall body of the wall, and the beam and the beam are connected with steel bars protruding from both ends of the beam. A certain gap is left between the beam and the beam, and crushed stone concrete 8 is poured into the gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com