A belt-wearing hydraulic elevator

A hydraulic and belt-threading technology, which is applied in the field of hydraulic lifting machinery and belt-threading hydraulic elevators, can solve the problems of slow lifting speed, large layout space, and reduced vertical size of the hoistway, and achieve stable descent and docking, installation and maintenance. The effect of easy maintenance and extended loading height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

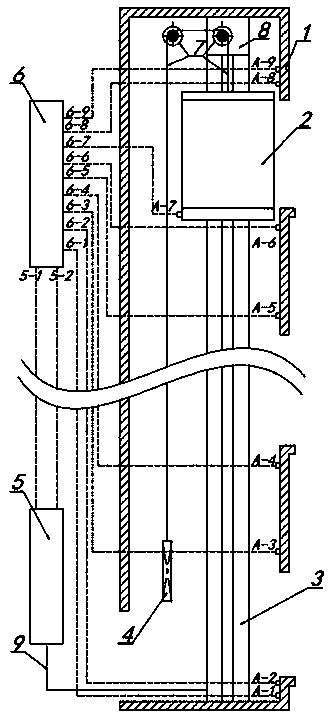

[0047] see figure 1 , a belt-piercing hydraulic elevator, comprising an elevator shaft 1, an elevator car 2, a hydraulic cylinder 3, a pulley rope group 7, a counterweight 4, a prestressing mechanism 8, a hydraulic unit 5 and a hydraulic pipeline 9, and an electric control center 6 , sensing components A1-A9 and signal lines 5-1, 5-2, 6-1-6-9, the hydraulic cylinder 3 is vertically fixed on the bottom or the side wall of the elevator shaft 1, and the top of the hydraulic cylinder 3 is connected to the prestressing mechanism 8. The pulley rope group 7 is fixed near the top of the elevator shaft 1, and one end of its steel wire rope is connected to the elevator car 2, and the other end is connected to the pair assembly 4; the sensing components A1-A6, A8, and A9 are respectively the limit positions arranged according to the floor Or speed change switch, the seventh sensing component A7 is installed on the elevator car 2, is the control and detection part of the elevator car 2, t...

Embodiment 2

[0050] This embodiment is basically the same as Embodiment 1, and the special features are:

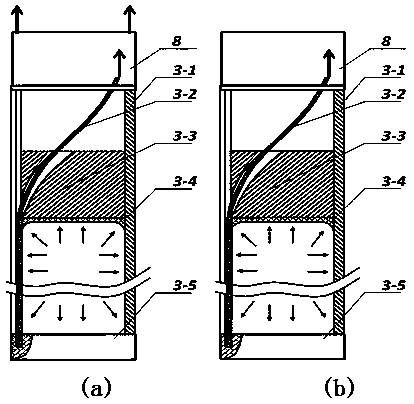

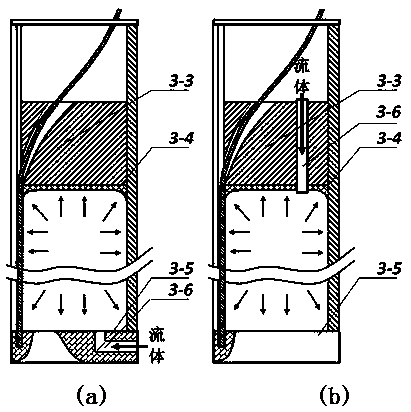

[0051] see figure 1 with figure 2 (a), the prestressing mechanism 8 is upwardly connected to the elevator shaft 1, and while providing prestressing force for the sealing strip 3-2 of the hydraulic cylinder 3, it also provides upward prestressing tension for the hydraulic cylinder 3 itself. This arrangement is more conducive to the stability of the hydraulic cylinder and the entire elevator system, and is recommended for elevators on higher floors.

Embodiment 3

[0053] This embodiment is basically the same as embodiment one and embodiment two, and the special features are:

[0054] see figure 1 with figure 2 (b), the prestressing mechanism 8 does not upwardly connect the elevator shaft 1, but only provides prestressing force for the sealing strip 3-2 of the hydraulic cylinder 3, and does not provide upward prestressing tension for the hydraulic cylinder 3 itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com