Full-lining ceramic ball valve special for thermal shock

A ceramic ball valve and thermal shock technology, applied in the field of ceramic ball valves, can solve the problems of poor performance of full-lined ceramic ball valves and incapacity in the overall situation, and achieve the effects of simple structure, reduced cost, and increased thermal insulation measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

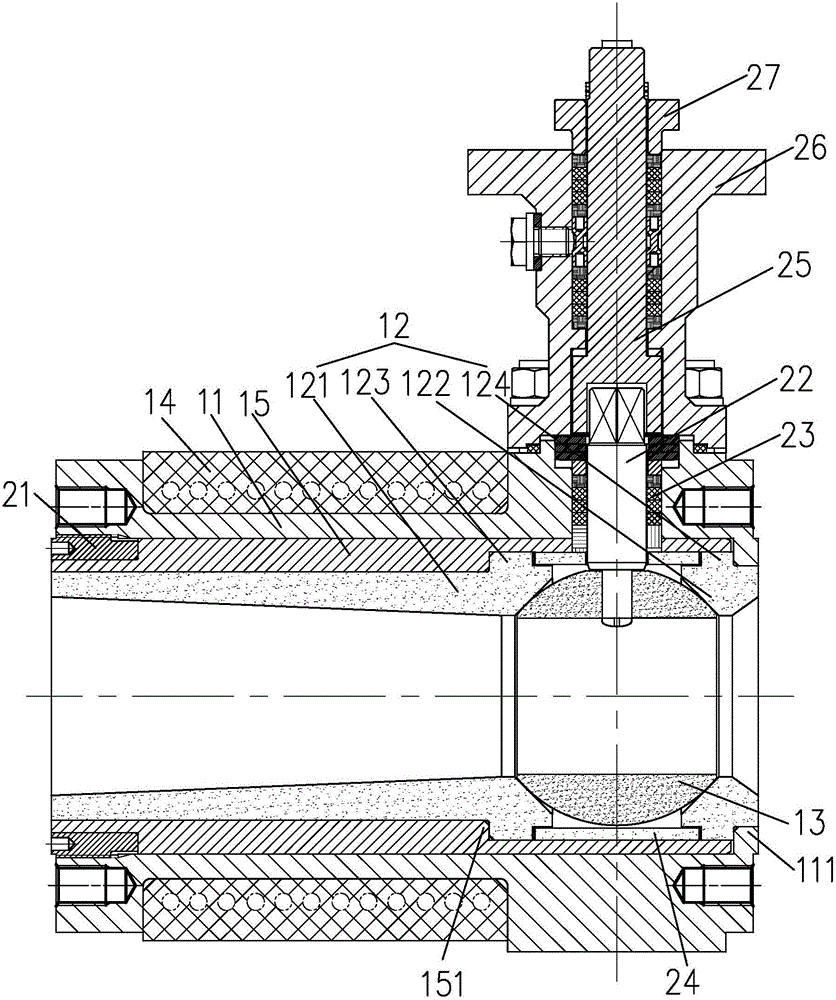

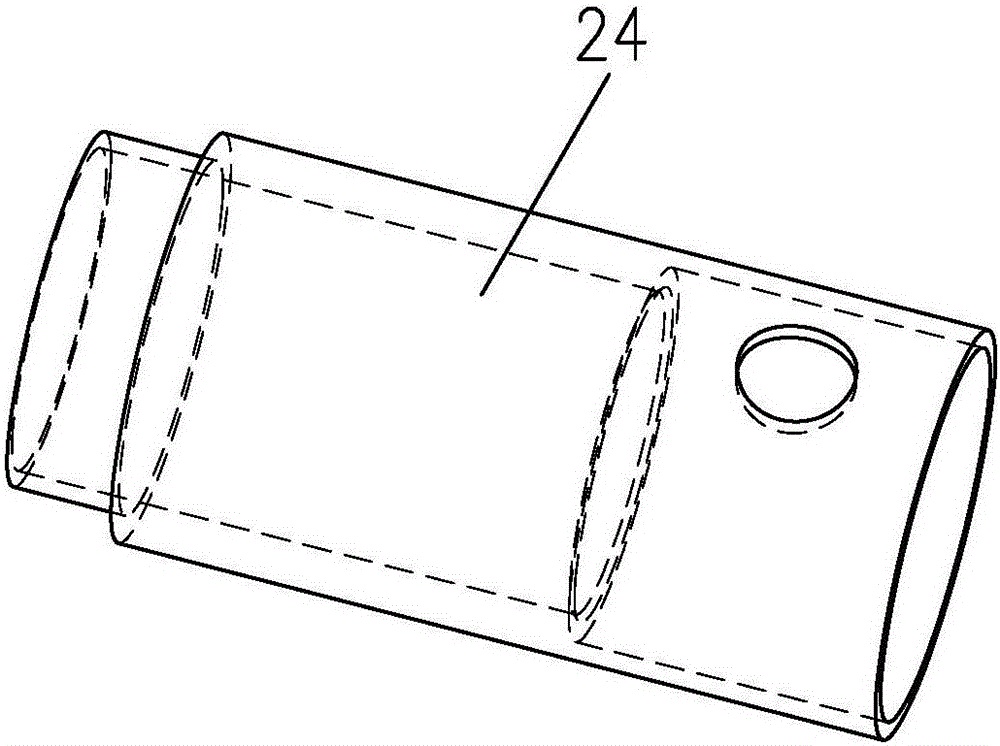

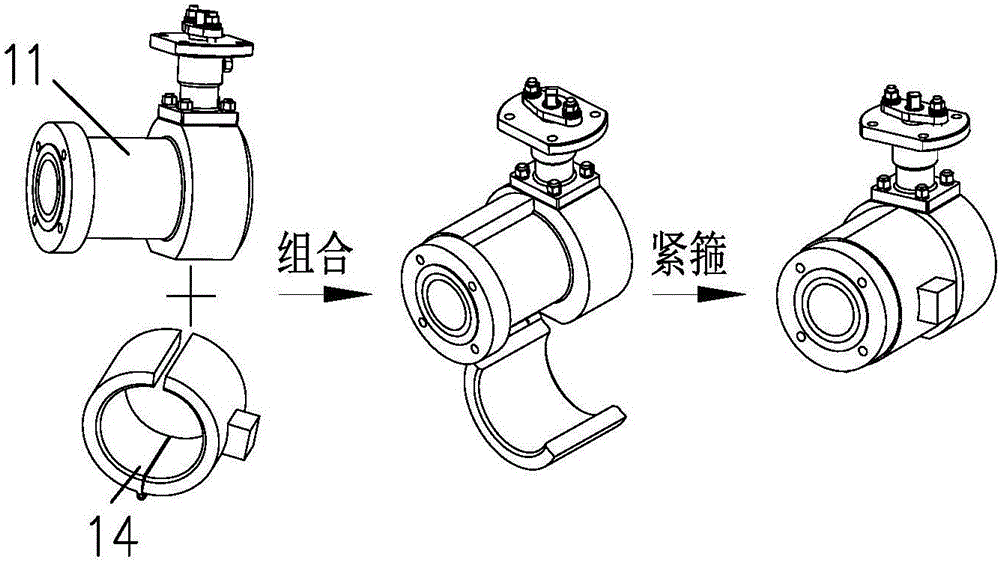

[0019] like figure 1 As shown, the full-lined ceramic ball valve for thermal shock of the present invention includes a valve body 11, a valve seat body 12, and a sphere 13, the valve body 11 is made of metal, the valve seat body 12, and the sphere 13 are all made of ceramics, and the sphere 13 is set In the valve seat body 12, the valve seat body 12 is arranged on the inner wall of the valve body 11, and an annular groove with a certain length is opened on the outer peripheral surface of the valve body 11, and a heating device 14 is embedded in the annular groove, and the heating device The size and shape of 14 are compatible with the size and shape of the annular groove, so that the outer peripheral surface of the heating device 14 and the outer peripheral surface of the valve body 11 at both ends of the heating device 14 are substantially flush after the heating device 14 is embedded, and the heating device 14 adopts electric heating, and a heat conduction lining 15 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com