Coating process of flange sealing surface

A flange sealing and coating process technology, applied in coating, damage protection, pipeline protection and other directions, can solve the obstacles to the normal operation of oil and water treatment equipment and transportation pipelines, destructive accidents, damage to oil and water treatment equipment and transportation pipeline anti-corrosion systems Integrity and other issues, to solve the problem of anti-corrosion protection and eliminate slight deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

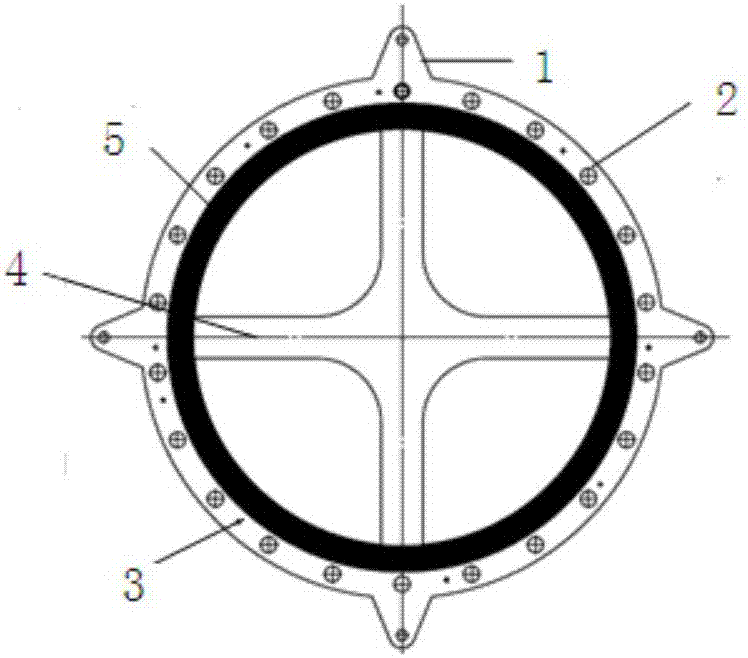

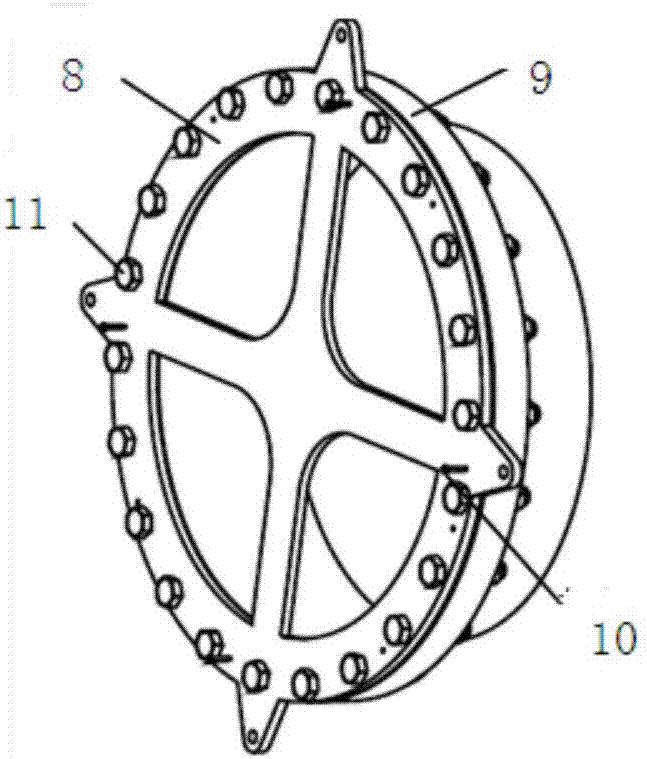

[0033] Such as figure 1 — Figure 5 Shown, the present invention adopts following steps:

[0034] The first step: sandblasting the sealing surface of the flange 9;

[0035] Step 2: Apply a release agent on the surface of the sealing water line 5 on the sealing surface of the mold 8, the connecting fastening bolt 11, and the surface of the ejection bolt 10;

[0036] Step 3: Brush the paint on the surface of the sealing water line 5, and scrape the paint flat on the basis of the plane where the fastening bolt hole 2 is located; at the same time, brush the paint on the sealing surface of the flange 9 to make the middle part of the flange 9 Form raised "ridges", and then scrape the paint evenly;

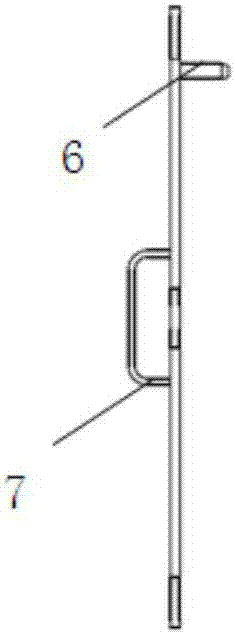

[0037] Step 4: Hang the lifting point 1 on the mold 8 by the hook of the crane, then, hold the handle 7 on the crane to adjust the angle, and use the positioning pin 6 to align with a lifting bolt hole 3 of the flange 9, and insert positioning;

[0038] Step 5: Use the fastening bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com