Polythiophene modified cold zinc coating and preparation method thereof

A technology of polythiophene and cold coating of zinc, which is applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of short cathodic protection time and achieve the effects of improving corrosion protection, increasing dispersibility, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

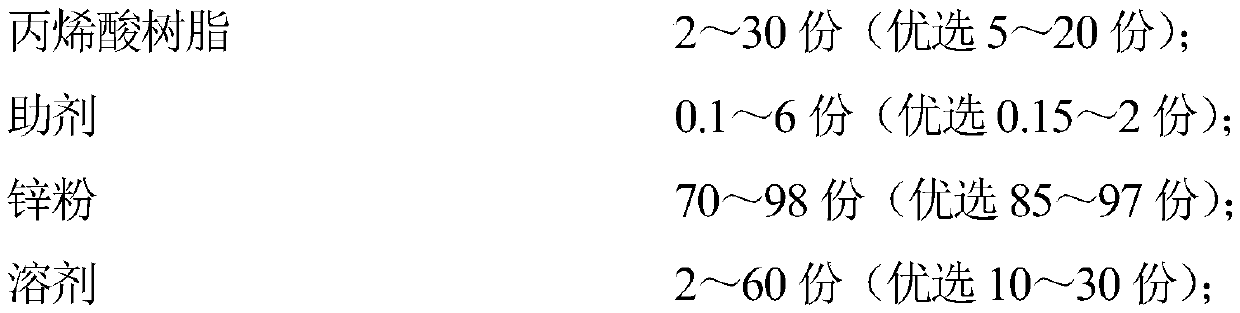

[0026] The preparation method of the polythiophene modified cold coating zinc coating of the present invention is carried out in the following order and steps:

[0027] (1) Preparation of modified zinc powder

[0028] Add solvent into the reaction kettle, add 0.5% to 20% polythiophene aqueous solution of the solvent mass in the stirring state, then add zinc powder according to 10% to 70% of the solvent mass, heat to 20°C to 50°C, and react for 0.5h to 3h ; After the reactant is centrifuged, take out the powder, rinse it with a solvent for 2 to 5 times, then dry it at a temperature of 40°C to 70°C for 10h to 24h, and then grind it into powder to make modified zinc powder;

[0029] (2) Add acrylic resin, solvent, and additives to the reaction kettle in sequence, and disperse at 300rpm-1000rpm for 15-50min; then slowly add modified zinc powder, disperse at 300rpm-1000rpm for 30min-100min, filter and discharge , made of polythiophene modified cold coating zinc paint.

Embodiment 1

[0032] In this embodiment, deionized water is added to the reaction kettle, and 1% poly(3,4-ethylenedioxythiophene) aqueous solution doped with deionized water quality is added in a stirring state, and then Add zinc powder according to 40% of the mass of deionized water, heat to 30°C, and react for 1h; Powder, made into modified zinc powder;

[0033] Add 166.7kg acrylic resin, 200kg toluene, 0.4kg Disperbyk-140 dispersant, 0.5kg BYK-055 defoamer, 0.4kg EFKA 3600N leveling agent, 0.4kg BENTONE 52 anti-settling agent into the reaction kettle in sequence, at 700rpm Disperse at rotating speed for 20min; then slowly add 833.3kg of modified zinc powder, disperse at 1200rpm for 70min, filter and discharge to make poly(3,4-ethylenedioxythiophene) modified polystyrene sulfonate doped Cold-dip galvanized paint.

Embodiment 2

[0035] In this embodiment, add deionized water to the reaction kettle, add 8% poly(3,4-ethylenedioxythiophene) aqueous solution doped with sodium polystyrene sulfonate with deionized water quality in a stirred state, and then Add zinc powder according to 40% of the mass of deionized water, heat to 30°C, and react for 1h; Powder, made into modified zinc powder;

[0036] Add 166.7kg acrylic resin, 200kg toluene, 0.4kg Disperbyk-140 dispersant, 0.5kg BYK-055 defoamer, 0.4kg EFKA 3600N leveling agent, 0.4kg BENTONE 52 anti-settling agent into the reaction kettle in sequence, at 700rpm Disperse at a rotating speed for 20min; then slowly add 833.3kg of modified zinc powder, disperse at 1200rpm for 70min, and discharge after filtration to make poly(3,4-ethylenedioxythiophene) cold water doped with polystyrene sulfonate sodium. Galvanized paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com