LED lens designing method capable of achieving hexagon uniform illumination

A technology of LED lens and uniform lighting, applied in lighting and heating equipment, components of lighting devices, lighting devices, etc., can solve the problems of low production efficiency, large volume, fragile, etc., to improve production efficiency and simple construction method , the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

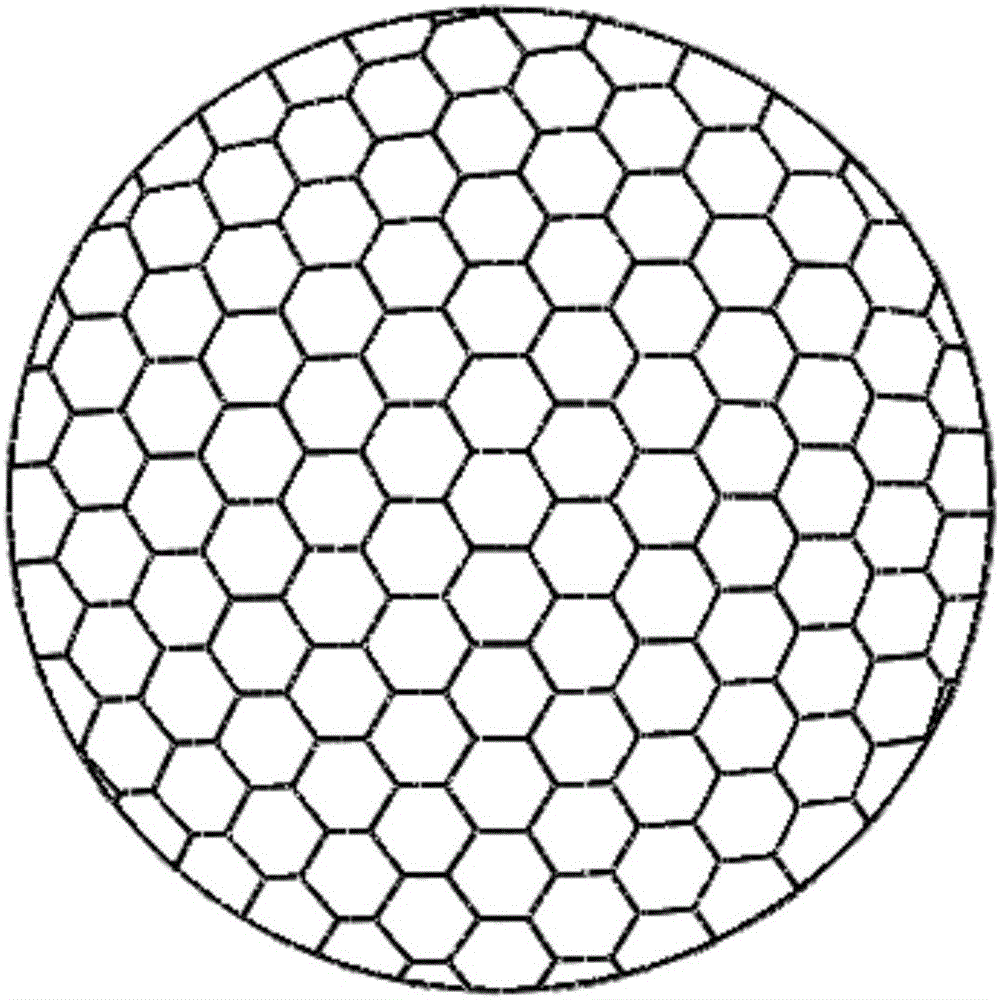

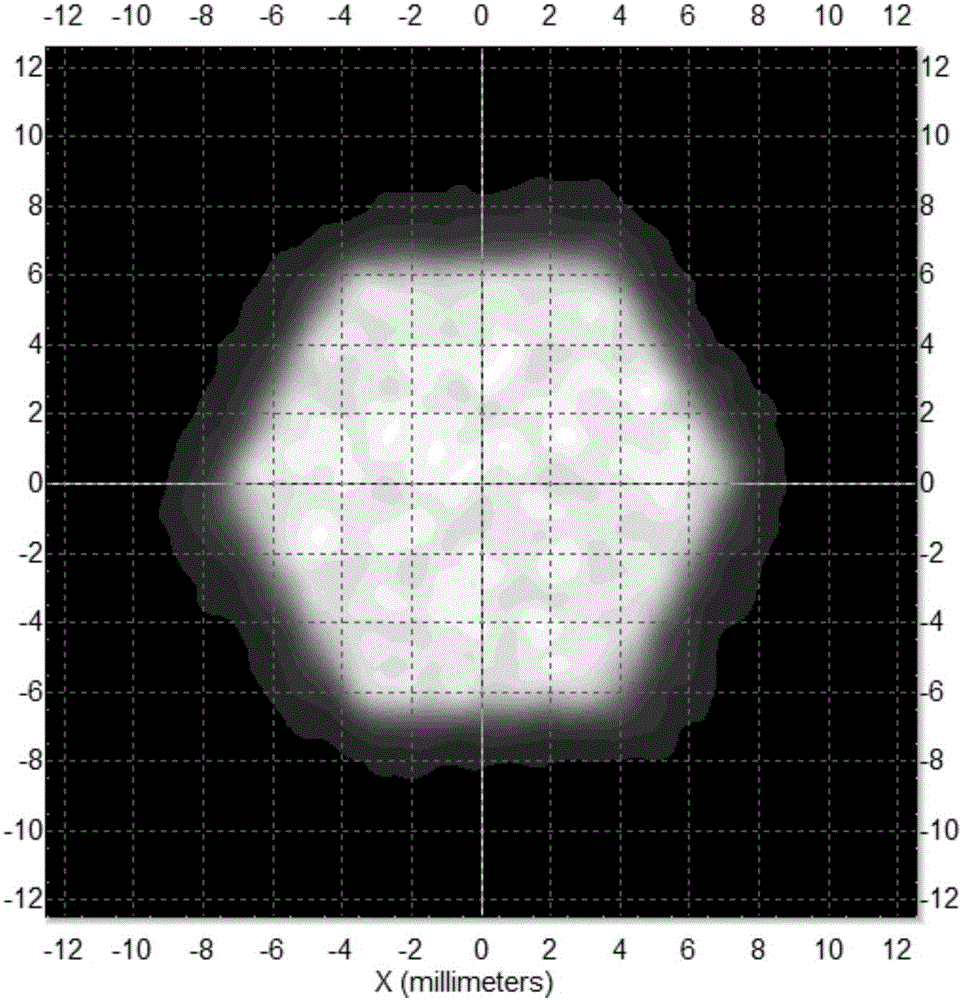

[0017] Aiming at the existing single-shaped lighting spot, a hexagonal spot is designed. Based on Snell's law of refraction and the principle of compound eye bionics, the light emitted by the LED light source is refracted by the lens and then reaches the irradiation surface. Optical design is carried out so that the required spot shape is formed when the light reaches the irradiation surface. Since the LED chip is a rectangle, the shape of the chip is ignored during design, and it is designed as a point light source. First, the light at a specific angle passes through an afocal system lens to make the outgoing light parallel, and then passes through the fly eye lens to emit the light into a beam with a hexagonal spot.

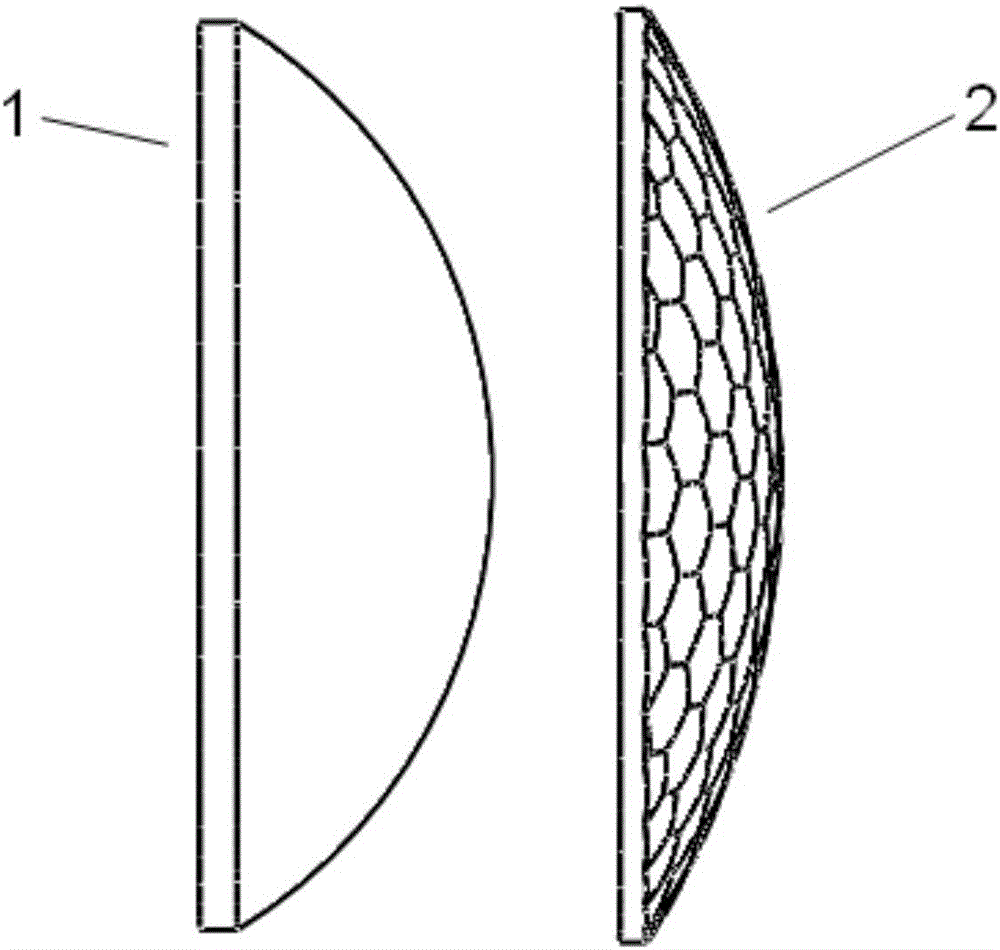

[0018] Such as figure 1 The schematic diagram of the LED lens structure with uniform illumination of the hexagon is shown, and the specific implementation steps of the design are as follows:

[0019] Step (1) Build the afocal system lens 1, the shape of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com