Liquid photothermic conversion solar thermal collector

A solar collector and heat conversion technology, applied in the field of solar energy utilization, can solve problems such as excessive energy consumption, cumbersome additional facilities and operations, and achieve the effects of reducing heat dissipation loss, improving receiving efficiency, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

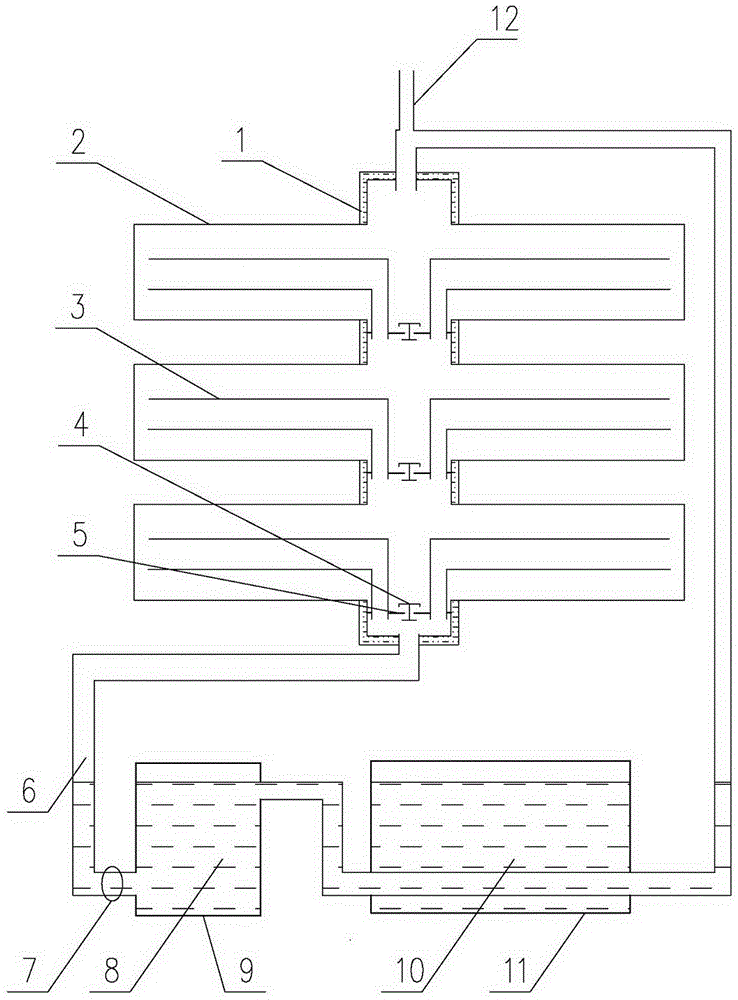

[0014] The liquid light-to-heat conversion solar heat collector includes a vacuum tube connection box 1, a vacuum heat collection tube 2, a liquid pipeline 6 and a pipeline pump 7, a plurality of vacuum heat collection tubes 2 are connected to the vacuum tube connection box 1, and a liquid pipeline 6 is connected to the vacuum tube connection box 1. There is a liquid medium 8 in the circulation pipeline, and the pipeline pump 7 in the liquid pipeline 6 is the power of the liquid circulation; an exhaust port 12 is arranged above the vacuum tube connection box 1, and the vacuum heat collecting tube 2 is a tube A transparent vacuum tube without coating on the wall, the liquid medium 8 is a black liquid, and the liquid medium 8 in the embodiment adopts water-soluble carbon black water. A convection water pipe 3 is arranged in the vacuum heat collecting pipe 2, and the water inlet of the convection water pipe 3 is located in the vacuum tube connection box 1. There is a sealing baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com