Airtight chamber and method for balancing air pressure inside airtight chamber

A closed chamber and gas technology, applied in the direction of sampling devices, etc., can solve the problems of incomplete vacuuming, poor sealing performance, poor corrosion resistance, etc., and achieve the effects of good air tightness, accurate test data and good test reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

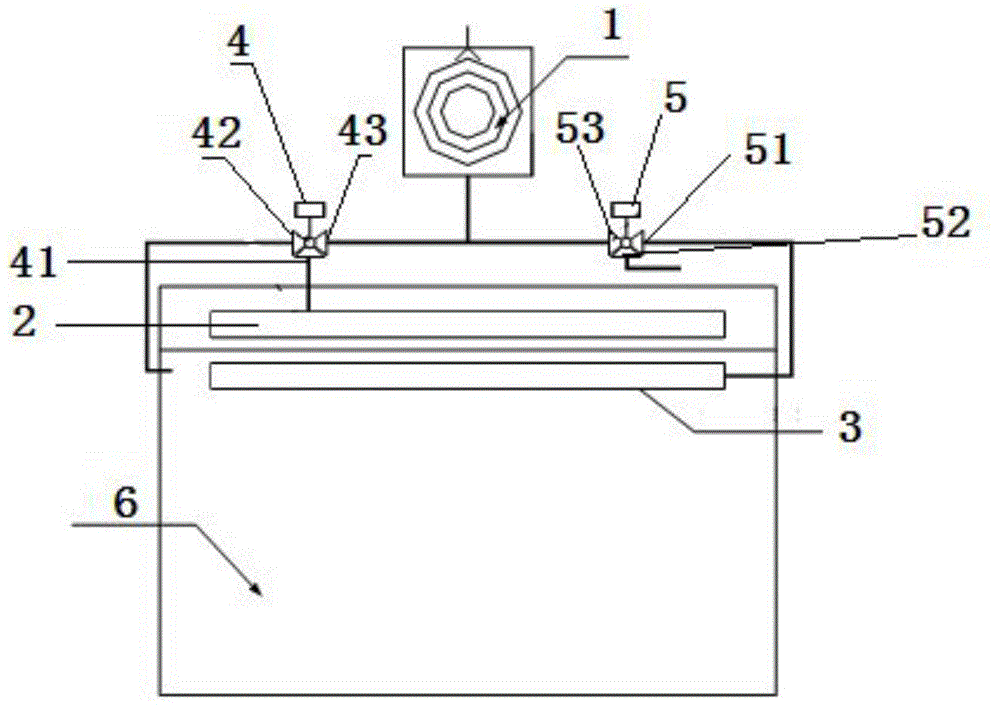

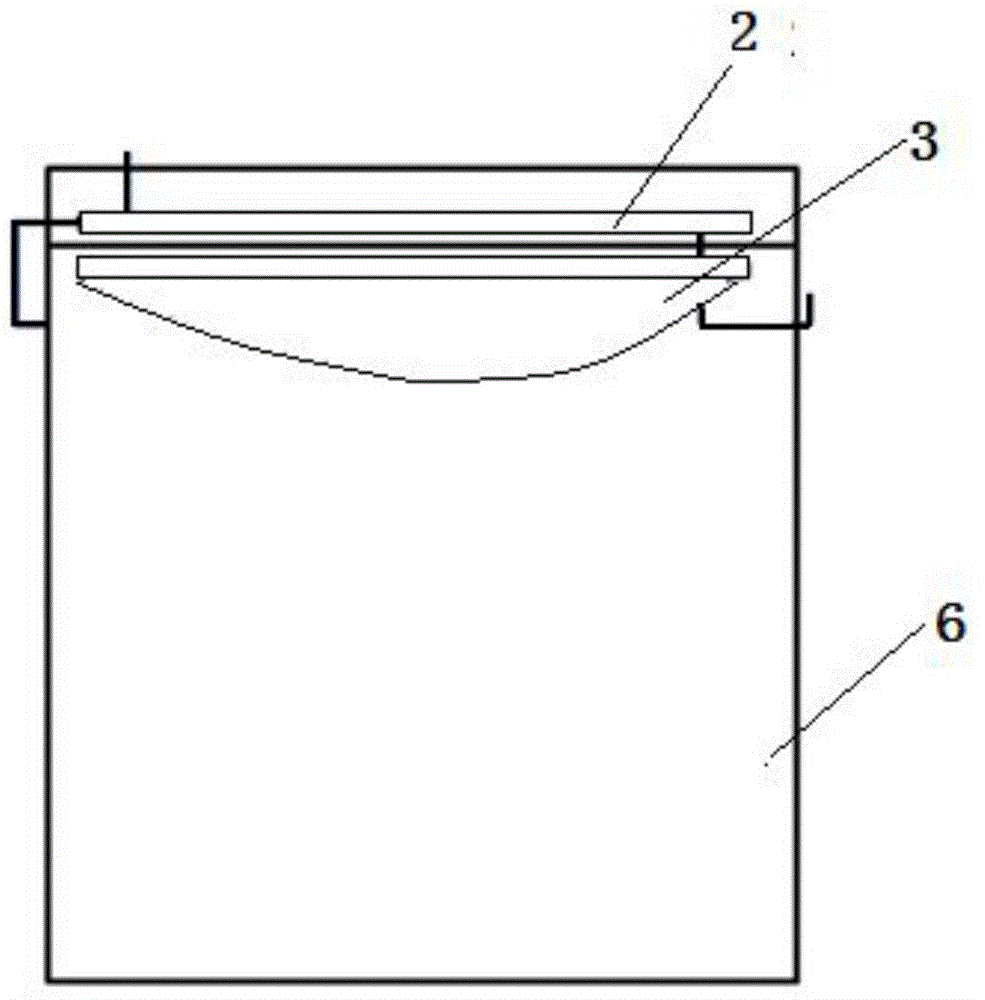

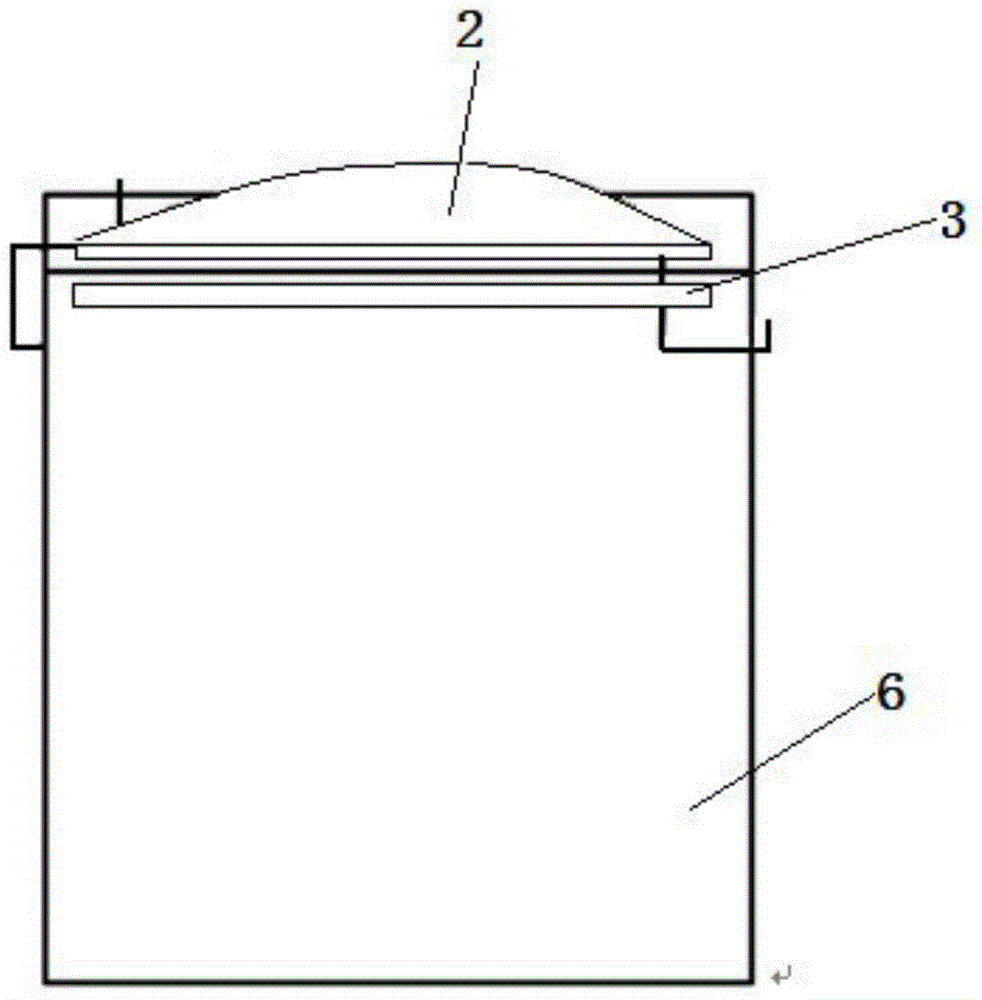

[0019] Such as figure 1 As shown, a closed room with balanced air pressure includes a vacuum pump 1, a gas collection bag a2, a gas collection bag b3, a three-way pneumatic rotary valve a4, and a three-way pneumatic rotary valve b5. The gas collection bag a2 is arranged in the closed room 6 Externally, the gas inlet and outlet of the gas collection bag a2 are connected to the port a41 of the three-way pneumatic rotary valve a4, the port b42 of the three-way pneumatic rotary valve a4 leads directly to the inside of the airtight chamber 6, and the gas outlet of the three-way pneumatic rotary valve a4 c43 is connected with the vacuum pump 1; the gas collection bag b3 is arranged on the ceiling in the airtight chamber 6, and the gas inlet and outlet of the gas collection bag b3 are connected with the port d51 of the three-way pneumatic rotary valve b5, and the three-way pneumatic The port e52 of the rotary valve b5 is directly connected to the atmosphere outside the airtight cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com