A Crack Detection Method of Steel Beam Based on Image Processing

A crack detection and image processing technology, applied in the field of fault diagnosis technology and signal processing analysis, can solve problems such as low efficiency, effective detection of difficult steel beams, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

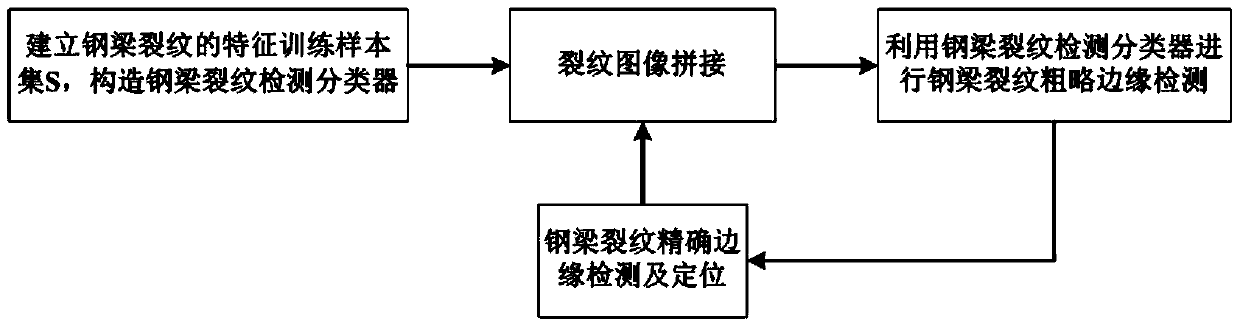

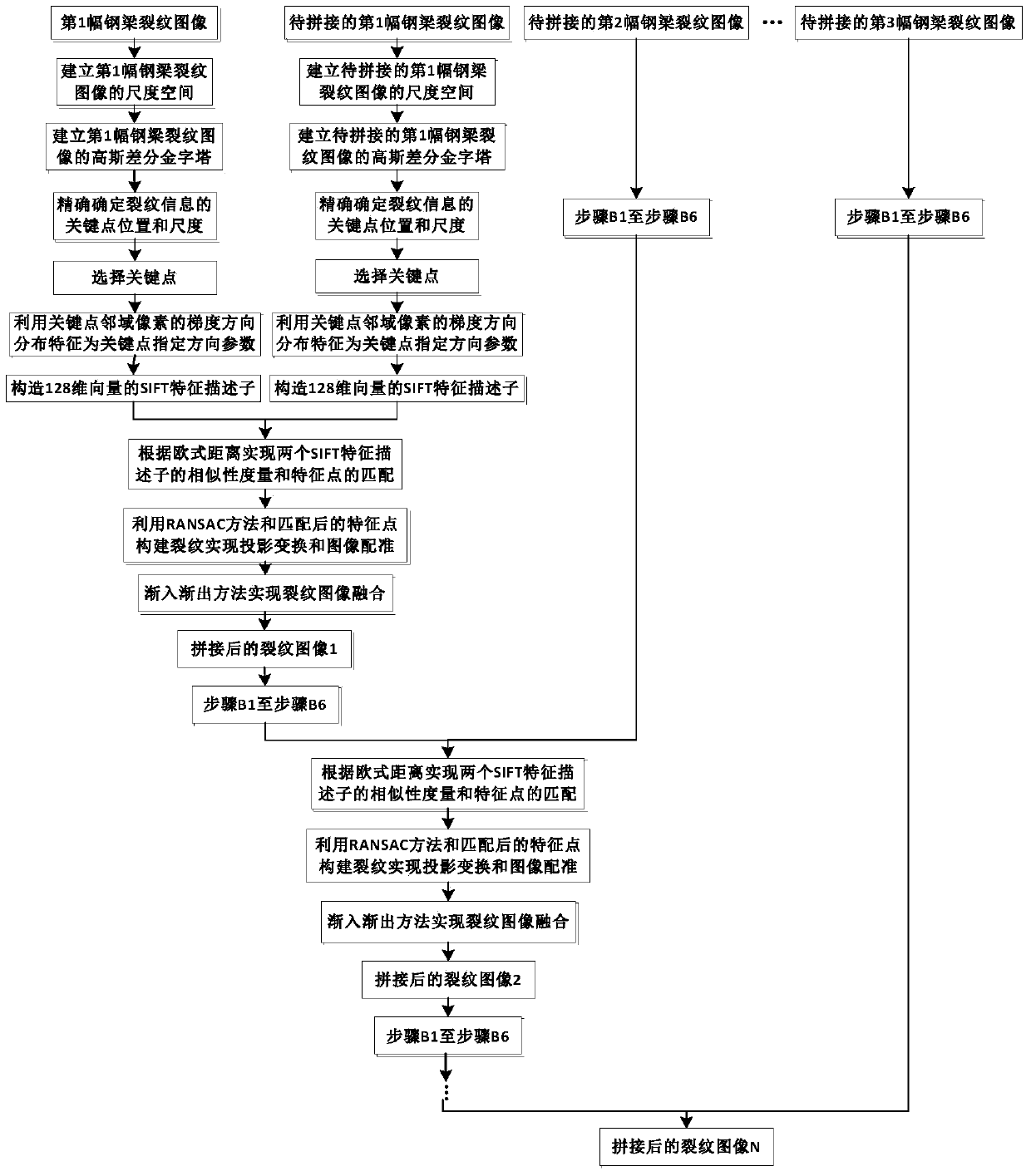

[0050] Embodiment 1: as Figure 1-10 As shown, a steel beam crack detection method based on image processing, first establishes a feature training sample set of steel beam cracks, and makes a Ground Truth set of sample images, and establishes a steel beam crack detection classifier based on structured random forest; then Splice the crack images in each time period in the collected images; use the generated steel beam crack detection classifier to perform rough edge detection of steel beam cracks on the spliced crack images, and obtain rough edge detection results; finally, rough edge detection As a result, accurate crack screening and positioning are carried out.

[0051] The specific steps of the steel beam crack detection method based on image processing are as follows:

[0052] Step1. First extract the steel beam crack image, establish the feature training sample set of the steel beam crack, and make the Ground Truth set of the sample image, together constitute the train...

Embodiment 2

[0077] Embodiment 2: as Figure 1-10 As shown, a steel beam crack detection method based on image processing, the concrete steps of the steel beam crack detection method based on image processing are as follows:

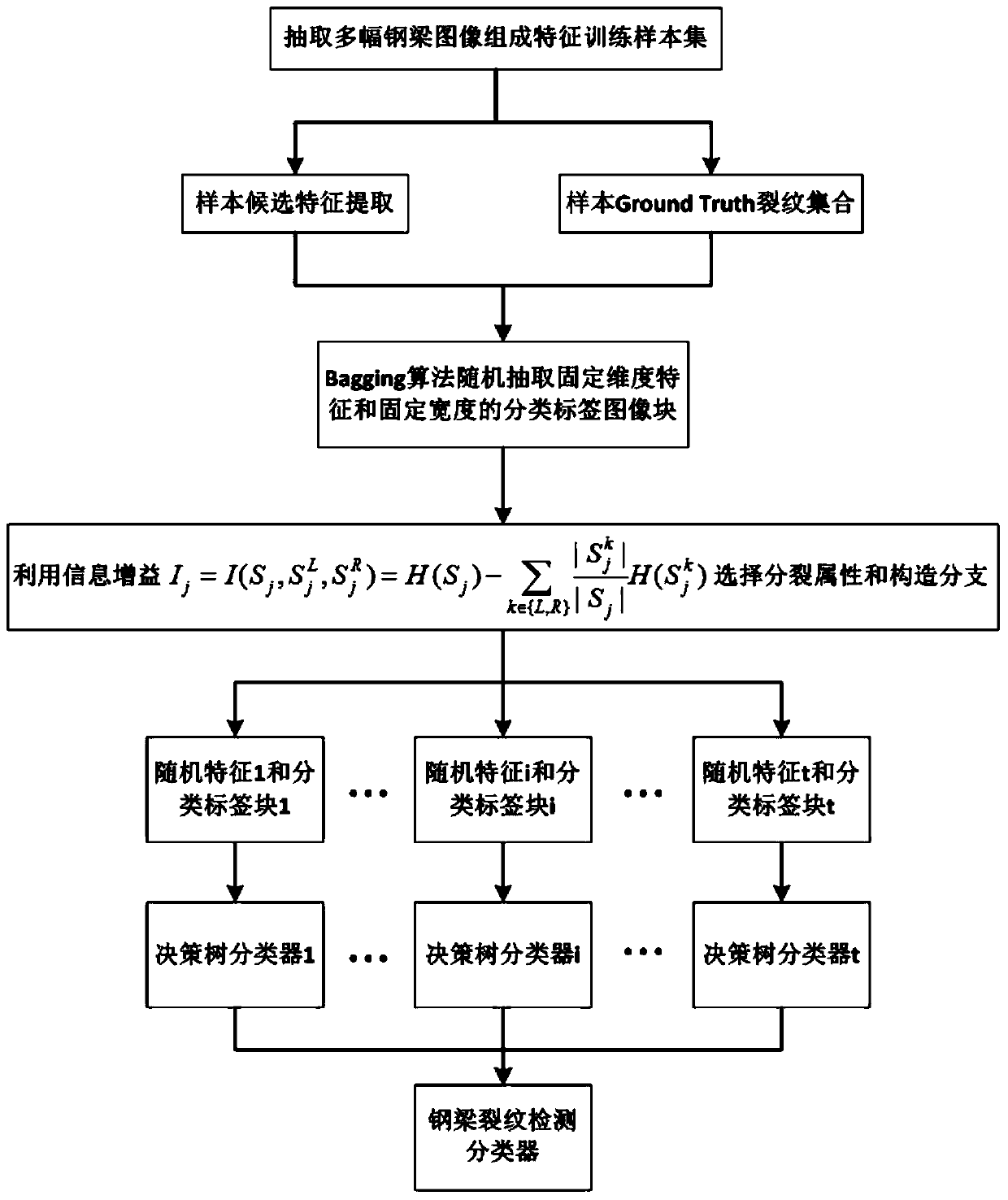

[0078] A. First extract the steel beam crack image, establish a standard 6m square steel beam crack feature training sample set, and make a Ground Truth set of sample images to form a training set S based on the steel beam crack image; secondly, establish a structured random forest The steel beam crack detection classifier h(x,θ j ), the flow chart of constructing the crack detection classifier is as follows figure 2 As shown, by establishing the training set S of node j j ∈X×Y, establish h(x,θ j ) in the random variable θ j The forest model that can maximize the information gain makes the output of the steel beam crack detection classifier a discrete value;

[0079] In the step A, the main steps of constructing the steel beam crack detection classifier are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com